All Suzuki ECU, and for sure the pre 1996 ECU’S LOVE TO FAIL.

See TCM here (the 4sp tranny brain 91-96) In 1997 they moved the TCM in to the ECU , & now called, PCM.

Focus:

1989-1998 Suzuki Sidekick’s and Geo Tracker’s ECU Engine Controller Units Details and tests, in the USA.

This page (1st published in 2007) covers the most rudimentary repairs & failures ,tests , the most common! Advanced ECU testing, is both complex, and expensive.

I have personally, have tested many pre 1996 ECU on car and on my bench tests jigs, (with custom signal simulators) I have tried, to force every kind of failure, possible and results.

I have discovered personally, and wth 100s of others, that starting in 1996, The Cap.s don’t fail. If Suzuki had used, ‘icon UPJ cap.s, most of this page would be moot.

Most CAP.’s have a design life or about 20 years, but some beat this hands down, in the real world, if not true, just about all things this old would be dead, and are not.

Keep in mind the Suzuki cab temperatures can hit 200F degree’s parked in the sun. 100C approx.

The ECU will not operate correctly unless it has good power and ground, (battery 10vdc min. to about 15v is max.) Yes, do check the voltage to the ECU power pins, if ECU acts odd.

Normal battery voltage is 12.6vdc rested, and 13.3 to 15vdc running.

The Main relay must be energized at key on, or the ECU will never get DC power to operate.. If you have power, then the CEL lamp glows, if not?, find out why first !

The ECU will also mess up, if inputs (sensors) are wrong. (it’s a computer, and all computers do that…) (finding cause, scan tool free, can be a harrowing experience)

Rule 1: No ECU (or PCM , ECM, TCM) on earth, can tell you, what PART is bad or failed, it can only inform you ,which tests, or monitors failed. (only humans can find out what really is bad .)

On all 1989 to 1995 USA Federal ECU’s have the CEL lamp shared with the mileage NAG lamp feature. Nag Not found on California cars or outside USA cars.

Best practice is to just remove the NAG switch and ash can, it forever, nobody deserves the grief, pain, and nuisance of this leaded fuel warning, it’s not needed now.

Keep in mind the ECU is programmed to CUT fuel (injections) for many reasons. No injections, are not a sure sign of a bad ECU.

Use the main menu below, to see details on exactly your, ECU type.

My ECU pages, only purpose, is how to repair the easy and very common failures, or where to find a good ECU.

Do not let the FUD mongers convince you , that you are helpless. (Fear, Uncertainty and Disinformation)

- Refurbished , Exchanges and Repair shops &USED ECU’s (Cardone is #1 and they have R&R too !)

- My large Capacitors (CAP.’s) are leaking what are the best to buy and who sells them (Mouser.com).

- Is my ECU still virgin “OEM ORIGINAL” ( untouched and in need of CAP changes?)

- The relays, or VSV, ISC all clicking madly

- Most ECU FAILURE MODES

- How to remove ECU.

- A FAST ECU test, take the 8 tests , it’s easy !

- ECU Part numbers , of all N.American Sidekicks, and all Trackers. (not all markets !)

- Full details on the 8 valve ECU’s G16A TBI 1 injector ( This ECU has p/n 56B30 or 40 or close on the side and a Big green connector )

- Full details on the 92-95 16 Valve ECU, G16B, MPI 4 injectors (with yellow connectors x3)

- Full details on the 1996 + ECU (first OBD2 ECU)

- FAQ

- Things the make ECU look bad, but ECU is not bad. (vast)

- A DIY way to test bipolar transistors.

- Parts Substitutions (IC’s , SIP’S, DIP’S , SMD, Hybrids and Transistors)

- See all ECU Schematics, (not inside the ECU, but ECU to car body wiring)

- Buy Injector drivers transistors.

- DTC code 53 from HELL

- How to prevent my car from blowing up the new ECU!

All general information below:

96 to 98 ECU never fail for bad CAPs. ( 96-98 only fail for bad injectors, if at all , ever) (hot wiring, excepted)

The Top reasons for ECU failures: See the bad Cap slide show for the leaks and to discover lost (acid damage) POLARITY marks!

See my secrets folder.

Common causes of ECU Failure:

- 1989-95 (only) The Electrolytic Cap.’s have not been changed out yet (1 time), Rubycon Disease. Kick the Ruby’s to the curb now. Use 2013 or newer date coded caps. never 2003-4.

- Hot wiring any ECU, and for sure the injector lines. The bad practice, of using a jumper wire from battery or ground to ECU output pins. (you let the smoke out, sorry!)

- Hot wiring the TPS or ECT you risk blowing up the ECU +5vdc-ref power supply.

- Hot wiring the fuel pump relay is an open inventation to blowing the ECU main relay diode to kingdome come,. seen many. D102 on many ECUs

- Injectors shorts, can act just like hot-wiring, as does injector wire harness shorts.

- Running the Engine with the battery cables pulled. The Alternator can go berserk, and hit way over 20 vdc and blow up a perfectly good ECU, and FRIENDS ! (old school

, never dies)

, never dies) - Jumper starting the battery, in car, using a tow trucks with 24 vdc power packs (old school truck). (BOOM ECU damage $$$$)

- Connecting battery cables or jumper starting the engine, backwards (reverse polarity), . This bad act, also blows up other expective parts too.. $$$$

- Got code 53?, (wrong ECU or wrong EGR main)

The ECU has a reversal protection diodes inside, but why tempt fate.? with battery reversals,. and all the other electronics in the car, Audio gear, etc.

The ECU will be fooled by the following things: This list proves the FSM quip ” never condemn any ECU until all this is checked first”

- Bad DC power feed to any EFI parts. (fuses blown or main relay bad or dead)

- Bad sensors (reading crazy for any reasons whatsoever)

- too low or too high fuel pressure,

- A Bad engine. (low compression on one or more cylinders, or low or bouncing vacuum and induction air leaks.)

- Stuck open EGR or melted CAT converter (clogged)

- Bad injectors, dead,clogged, leaking ,or sticking.

In neon lights, and trumpets blaring load and hard, you see?: THIS IS FIRST on all cars. Just one 5 minute check.

THE +5 VDC REFr ECU PIN: (it is just an ECU generated, power source to some EFI sensors. TPS, MAP (8v)

It is a Gray-red wire and when this wire is dead, the TPS is dead. On 8v, the MAP dies too. “limphome happens”

The only Causes are: (disconnect all 5v sensors, if 5v is still bad, then the ECU is bad, or has no power to ECU)

(4.5 to 5.5vdc is typical good reading) 0v volts be bad.

- Blown fuses in cab fuse box, the ECU has 3 fuses. IG coil, FI, and Dome,

- A cut +5v wire (open circuited) from ECU to TPS (this is true if directly at ECU pin, the Gray-red reads good, but measures, bad at TPS)

- Wire grounded out, to car body ( this is true, if when you disconnect the Gray -red wire , the voltage returns to normal) hint: Unplug TPS and MAP. Shorted MAP?

- Bad ECU , note how I assume it’s not , until I prove it is bad here. Replace ECU LAST. Spares are like $500 so… last.

IF CEL lamp is out ,key on, no start, then the ECU has no power, (fix that 1st) or the lamp is bad, or the Prev. owner, black taped it out.(missing lamps …?)

The schematic pages show all the other ECU power pins (all pins).

The power to the ECU must be good and so must the main power feed in the body of car, fuse box 1 and 2.

The ECU must have good power (over 10v) and must have good inputs, or the ECU outputs can be bad.

The battery must be good and charged, 12.6v is charged, at about 9-10vdc the ECU drops dead. (approx.)

Most newer cars spec the PCM power at 10 to 16 vdc.(operating range)

The ECU can not report all errors, in most cases, only the worst errors. (this improves greatly in 1996 but is never “AI” like, at all)

Let me give an example of this, It can not tell you if the thermostat (coolant) is bad or the ECT reading wrong.

The old ECU can only warn you of dead ECT.

New cars can warn of , ECT is slow, or slow get to normal temperature or too slow to reach closed loop. (a bad thermostat) ECU’s have evolved.

Do not hot wire the ECU!

The ECU can mimic bad sensors and will seem to run ok, but is not okay, the mimic is part of the limphome, and MPG will be near 15 MPG (horrid) (pre 1996 cars are worst)

Keep in mind, all failures can happen with just 1 bad wire in the EFI system. See Wires BAD.

Do not condemn the ECU for the Stuck on CEL(SES) lamp , slide the NAG switch (1989-95 only , USA Federal bodys only)

Do not condemn any ECU, until you proved the inputs to it, are good and the output devices work, (injectors) or if Distributor spark, is bad.

This page does not solve all 1000 of possible ways to ECU fail, but does cover the 2 main fail modes. (Bad CAP.’S “large capacitors” and bad drivers {all bad outputs covered}

A bad CAPs’ inside ECU, can cause the powersupply regulator (inside) to lose control and the ECU to crash or reset constantly, with horrid results.

The ECU is just a microcontroller, a computer, and as such , wrong inputs , will result in wrong outputs. Known as GIGO , garbage in? , garbage out!

The ECU can not inject fuel with out proper fuel pressure (30psi) or a clogged/leaking injector or any injector with an OPEN coil.

Not all bad OLD ECU’s can be repaired, repeat NOT ALL ! (only by cannibalization of 1 , and 2 ECUs parts to make 1 good ECU, in many cases)

Or not at all (burned up main board, acid damage gone wild, etc)

The hybrid chips have no published schematics, nor are they sold new. This limits repairs, greatly and reverse engineering and substitutions (vastly).

ESD? issues? Do not zap your electronics.

First things first: (CAP means Electrolytic Capacitor. CAP for short ) and no others… non of the other cap technologies, fail . Cermamic, Mylar, etc.

The EFI system and ECU works like this.

Most caps have a design life of about 20 years, most top brands, do that ,times 2.

The 3 large Cap.’s must not read zero uF, leak , short, open or be dried out. See how to buy em’.

What pray tell is uF?, it means Micro Farads. The Cap.’s are clearly marked for uF and volts. (do not use less volts or uF, is a general rule)

That corner PCB, cap loves to leak acid and eat the traces up real bad, the ECU will never run right again with bad traces. See my slide show for how it should look.

What are traces, well , those are the copper lines that connect all the parts on the board, the board is a PCB, a Printed Circuit board. Circuit card.

The caps , mostly have -20% lower limit , so 50uf must be no lower than 40uF, but I know all new caps read way high new, so if they read low, out they come. (paranoia wins here…)

All 89 to 95 ECU’s fail for bad electrolytic Capacitor’s just 1 time, if you replace them with a quality brand. See comments later on choices.

If the CAP’S leaked boric acid , and eat up the copper traces, only a technicain Pro can fix the copper damage. (jumpers added with great care)

NEVER EVER drill through the PCB, no matter how desperate you feel, It is a multilayer PCB !

Ok? (the main corner CAP , loves to do that, and wrecks the main power feed that passes nearby.)

That same corner cap , i’ve see the plated through holes are bad, (called Via’s by Pros) Some times Acid cause, or poor service shop proceedures.

Do not condemn any ECU/ECM or PCM. without first checking: (dead spark or no fueling) Engine will not run. (new order)

The ECU (Brain) is only as smart as it’s inputs.

- There are 3 Fuses for Power, The FI , IG-COIL and the DOME fuse must be good and must be hot KEY ON. Test them with a ohm (resistance) meter ,0 ohms is good, Infinty is bad.

- LOW FUEL PRESSURE , Below 30 PSI fuel pressure will cause no starts, or very low engine power. Check the fuel pressure with a real fuel pressure gauge, DO NOT GUESS !

- The ECU keeps blowing the ECU fuses above random or at speed bumps?, see clicking relays.

- No DTC error codes live or stored in the ECU memory, if yes ?,address those failures first. Example ECU Inputs bad? ! DTC 12 is NORMAL (all others NOT)

- Battery must not ever be allowed to drop below 10 vdc (ECU will NOT work below that “about” ) Fix the battery or charge system first, charge the battery to 12.65v.

- The Grounds to the ECU must be good. (power and ground most be good. FIRST)

- The ECU must not have a low or a dead +5vdcREF power supply output pin (always check it 2nd, at the TPS “Gray-red wire” pin, is easiest to reach)

- Bad injectors. (clogged, leaking, open coils, or shorted coils) No ECU can run any engine with bad injectors.

- The ECU outputs must NOT BE GROUNDing out OR SHORTED OUT. EVER ! (no shorted injectors!) Grounded outputs will blow up this ECU and all new ones installed.

- Make sure your ECU wiring is not damaged in any way, cut, frayed, shorted to each other or ground. (or hacked up by Alarm or remote start installations)

- ECU’s with madly clicking Fuel pump, relay and VSV valves. Might be a bad ECU or Fuel pump sucking too much current. (normal pump, current is 4 amps)

- Lets say, you have spark and using test fuel the engine runs for 3 seconds and stalls, so you connect the NOID lamp up and it glows just keyon, not cranked. That is a bad ECU , the injector driver is shorted or the wires are bad from ECU to injector.

- If the ECU passes the NOID light test above, and you then crank the engine and the NOID flashes, be aware that at 300 RPM (strong battery CCA) the NOID will seem to glow, steady, this is normal.

- If the NOID lamp flashes and fuel pressure is over 30 PSI and the injector don’t spray, then the injector is clogged. The TBI engine, you can watch the injector with eyeballs, do so.

- The MPI engine, the spraying injectors cause the spark plug tips to drip in raw fuel, (look at them is the check here)

- The injector tests with NOID are not 100% conclusive , only using a scope, has 100% accurate. But see ways to get better NOID usage here.(4 ways)

- Keep in mind the TBI low driver, if shorted, the fueling will be flood stage, and you will be powerless to stop it. Both TBI DRIVERS must pulse or all accurate injections end. (but runs with black smoke)

- I will not attempt to go through each other bad output on the ECU, (VSVs dead or stuck on, relays, etc.) For those you must work just that exact failure with a volt meter.

- Last and not least, is the FSM ECU pin voltage checks, see details links here for those facts.

Never run any old pre 1996 ECU with out at least looking inside for damage ! IS MINE VIRGIN? (old caps,etc)

Smoke stains and signs (under ECU lid too), water damage, mud, bugs? , acid leaks, and CAP.’s with split open sides (cracks, tiny volcano’s venting acid? of the main Capacitors. (large can shaped objects)

One or two times, seen a tiny spider build a nest in the main ECU PCB altitude baro sensor, totally blocking this AIR port (hole) to said sensor. LOOK at it !

FYI:

Use this page to correct acid damage to the traces.

How to replace the Caps – video.

ELECTROLYTIC CAPACITORS: 1989 to 1995. Installed on the PCB , the Printed Circuit Baord, PCB for short.

If these cap’s were Nichicon UPJ series, we’d not be reading this… See how to buy em’.

To make my buddy happy, read ESD 10 times.

The are all “Can” shaped, Capacitors or CAPS for short.

They are all shaped like small garbage cans, or perfect cylinders for you Geometry buffs.

It is true, all Cap.s like this do not last 100 years, like Silicon IC’s can , IC’s have a design life of about 20 years or more. But not ELECTROLYICS.

No all Electroylyice makers are equal, from from it, and to be 100% sure, you can buy cheap caps or heavyduty cap, I list some of the best made in the world here.

The Number one failure mode for all ( 89-95 SIDEKICKS only!) is CAP LEAKAGE HELL. ( I bought new CAPS here)

Up to 3 CAP’s can be bad.

These 3 parts, sit on top of the main ECU PCB , Printed Circuit board.

These CAPS , either dry out (unseen) or leak, the leakage can get very bad. (see it here)

LOOK FOR: split sides, tiny volcano’s on sides, buldging tops or bottoms and the green slime.

But only a CAP meter, tells the truth. OR ESR meter works if they look ok with visual inspections.

The pre 96 ECU’s all love to fail for these 3 parts, the big corner one , is the #1 single failure.

Many shops get rich just replacing this one part! Then calling it rebuilt. (not Cardone , they do the best job , state side)

The #1 failing CAP brand is Rubycon , original parts. Some are 25 years old , today.

It is best, to change out any pre 1996 ECU CAPS, that are ORIGINAL.

The below is an ELECTROLYTIC CAPACITOR (called a CAP from now on) the other technology caps do not fail, (mylar, ceramic, tantalum, etc) Just the CAN type,fail.

This device, is POLARIZED (if the acid leak has not etched off the silk screened (painted words) component ID’s you will see Plus and Minus symbols on the PCB.

Some older boards, the designer used a ground symbol for minus.

This CAP below is leaking boric (typical) acid, it can leak, or crack the case and leak or make tiny volcano’s on the side, spewing acid like this one.

Once the cap is dry inside, you have just an empty CAP and zero uF value, the results are a ECU crashing over and over.. (rebooting endlessly, crazy actions.)

The main CAP, if bad will cause the on board Regulator to go nuts. (drop outs) Car electrical noise is huge, and the ECU is designed to work right , at huge noise.

If curious look at A/C clutch noise, with a weak battery or loose corroded terminals. NOISE ! or load dumps.

Bad 2:

The acid can eat the copper traces under it , and kill major functions in the ECU. <<The 2nd most common serious failure of this age group. (the corner cap, look under it)

One guy , found the + traces under the corner cap, destroyed, so he drilled a hole in the PCB, killing it for ever. Do not drill this multilayer PCB, you will be sorry.

(replace these CAPS , using the proper polarity, the CAP case stripe is MINUS and the PCB is marked + (plus) and a ground symbol (earth) or MINUS symbols.

You must Match Minus for Minus and Plus for Plus or the CAP will explode as power is first applied, some can be very violent.

Do not put your face near a first powered up PCB with NEW caps intalled.

You can be injured and have see it with my eyes, in a huge factory production setting. (flying aluminum chunks). (I wish I could forget all bad things seen in a factory, wish)

This corner CAP is a main power filter.

The one on the corner of the PCB is the worst. C111 (8v) and C103 (16v)

C111 swap out example, it’s not hard to do? Details. The longer version is here. I’m using full ESD protection and a ground strap to my wrest.

- Using my Weller WCC100 soldering iron, set to 700F on the dial, I Heat the bottom pads of C111 for 1 second or tad more, then at the same time

- I using my solder sucker, I suck the solder off the pad and the via through holes.

- I then heat the pad again and wiggle the CAP lead wire, so it is free of this VIA hole. These holes are called, “plated through holes or VIA’s for short.”

- The Cap now falls off the PCB and now you can install a new one.

- Insert the new cap , minding POLARITY, and bend (just a 45 degree tweak ) the leads, so it can not fall out of the PCB.

- Solder the new CAP leads to the pads. Using Ersin flux solder , never acid flux solder of any kind.

- Wash hands after touching any lead parts, and this PCB is lead. Do not eat or smoke while handling lead objects.

- I clean the flux off the pads ,with pure near Alcohol. Do not Clean the whole board, because it is conformal coated. Just your working pads.

- .Any trace or pad damage needs to be corrected. If not sure?, ask a pro. tech. (a jumper wire can be added, for sure)

The CAP’s can be tested, out of circuit.

Top branded DMM’s meters has a CAP testing mode (FARADS). like a Fluke 88V 1000V Automotive Multimeter (MicroFarads or uF)

There are vast meters sold at $100 that can do this , easy.

A good meter can read the micro farads, uF , and must read at least -20% of the stamped rating. so 50 uf must read at least 40uf, or as much as 90 uF.

+20% to -80% is the spec. on variances. Us old guys , from Radio days called uF mmF, or micky mikes.

Please ignore my stock photo below and the huge uF values. My main Kick Cap is 47uF.

The “u” in uF means Micro, and the “F” means Farads. Expunge#1, means “mark for deletion“.

In my mind, all Ruby’s are marked for removal. Tag em’ and bag em’ , huh?

Replace only these Large can Electrolyic’s they are the weakest link, in most electronics.

In our shop, we call them “weak technology”, for good reasons.

Or as my very old buddy says, ” it is , what it is !”

Funny how only the Rubycon brand fail from this era, odd , huh? But after 20 years all of these, are suspect. Read the data sheets carefully and life span.

When buying new caps, buy the Lowest rated ESR you can find. See how to buy em’.

just joking with Enema…only…

just joking with Enema…only…

See my CAP horror slide show on leaks.

Here is the 1989 ECU. See caps? Replace both CAP.’s on the left side.

You are here, because you have evidence that your ECU is acting weird, no CEL at key on, no code12 when commanded (diag jumper), no idle signals to IAC.

CEL lamp on full time (SES not ON) and will never go out, running. (and DTC codes will not flash out) When the happens ECU is in BACKUP mode.

This page is USA vehicle centric. There are 97 markets world wide and hundreds of ECU designs used by Suzuki and GM.

This ECU is OBD1 technology the one that likes to fail.

Your OBD2 (96 + in USA) ECU is most likely in perfect shape. I do have 96 OBD2 repair data ( new)

Let me list the classic fail symptoms in a list.

- The CEL will not come on ever, even though the lamp is good.

- The CEL stays on all the time, key on running and the Diagnostic Jumper is dead. NO FLASH codes. – First remove the SES NAG switch on all FED48 cars!

- The Diagnostic jumper is dead for any reason. (other that the SES nag switch reason)

- The Diagnostic codes start to come out and halt mid stream. (this is the ECU rebooting mid stride)

- Idle controls are dead , and ISC is good and TPS idle switch is good. (a symptom of ECU stuck in Limphome or worse BACKUP)

- Engine runs RICH and ignition advance are RPM are grossly limited, (again ECU is stuck in Limphome or backup and all EFI sensors and Engine are good)

- NO DTC code 12 when commanded via Diagnosis jumper or any other codes.

- The ECU keeps blowing the“FI” fuse over and over. (the CAP above keeps shorting can do so when you hit bumps in the road)

- ECU is flashing Code 53.

- ECU lid under side is covered in black soot.

- ECU CAPs are visibly leaking acid, or are split ,cracked or bulging.

- ECU CAP has exploded .

Just because the ECU is stuck in Limphome ,does not mean the ECU is bad.

BACKUP mode is ECU failure

Limphome is what ECU does when confused ( conflicting or dead, sensors cause that , and if true is a normal function to mimic dead sensors)

The ECU does go to Limphome (Fail-SAFE) for many reasons. Those reasons must be explored.

If the ECU still has Rubycon in it (orig) then your ECU will fail , and will do so soon, if not already happening.

If the CAP above dries out,the ECU will keep rebooting itself , endlessly or in a very random way.

This rebooting (resets self) causes , the ECU to work correctly one minute then fail the next.

ECU Part Numbers: My PDF LIST, needs Acrobat to view it.

All USA and Canada ECU part numbers: below: !

EPC = Electronic Parts Catalog. (ECU Excerpts)

Now annotaged for smog part changes… IAT, and EGR.

Real EPC ECU list, for all 89-95 1.6L cars in N. America.

Real EPC 96-98 ECUs list for all , 1.6L in North America

Last is:

Real EPC ECU list for all 1996 to 1998 Suzuki 1.8L Sport ECU P/N page 1, Page 2.

How to find a spare or replacement ECU (PCM) , TCM , etc. Engine or transmission controllers.

- GOOGLE IS YOUR FRIEND , just type in the ECU part number, in the search box and bingo, vast hits.

- I fix my own, but if I can’t, I buy the best:

- The best is CARDONE (also sold in all top , brick and mortar car parts stores in the USA)

- IF YOU call them (using a telephone, CELL?) CARDONE, they do fix some ECU’sby demand (R&R), This is an ISO-9000 shop, no bull.

- The next one is a joke , and is true.

- Ask a SUZUKI dealer? the price is $1700, that is the cost of a new ECU. You can look for your self, see it.

- See my list of Suzuki dealersstill selling parts, state side.

- Ask GM, here.

- Ebay has many, used, repaired, As-Is, and some rebuilts, some rebuilts are not really rebuilts , only fixed (patched up) The price, is the first clue.

- Goto the best wrecking yard, heaven place online,at Car-Parts.com, find the part in any state or all States. (pigs in pokes? sure)

- If you find the bad component using my page, you can find a Ham Radio guy or other big , true electronics repair shop, to do the replacment.

- No ,Geek squad is not going to fix your ECU. But a trip to any college electronics shop , you will find good help. Early pre-Engineers and techs. are here. Try them.

- No warranty is free, so expect to pay way more for any product with one. CARDON is the best. Here in USA.

Best practice, is to have a good spare at all times, in the future, finding good ECU’s , will be harder. Be proactive, in this regard.

R&R means: Repair and Return, return yours.

Keep in mind not all ECU’s are repairable, but most are! Damage has no limits (fire or lightning, floods)

Many of the Misubishi parts are no longer manufactured or stocked. (not a good thing at all, very very limiting to any technician)

If the ECU is burned to a crisp , it may be a total loss, or if the microprocessor, is bad ,this part has the SUZ ROM code for this car ,stored inside, and are not sold.

Some of the SIP (single inline package) parts are very hard to find and some are not sold new.

The same is true for other parts on this PCB, the WHITE hybrid SIP parts . PCB means Printed Circuit board, (the main green board) SIP means, single inline package.

Most shops that do fix these, ECU, get many key parts, from the practice of cannibalization.

Overview:

( #1 Failure is bad dried out Electrolytic Capacitors or leaking acid out the bottom of it, and collateral damage from these caustics leaks)

We call them Cap’s for Short !

The early “black Cap’s” are junk, they LOVE to leak , crack , blow up and leak acid over the Printed Circuit Board , PCB. (and eat up vital copper traces.)

What’smore? the old caps were designed to blow out the bottom (big time bad that) the new caps , top vent fail, saving the $500 main board.

When this happens, the ECU will constantly crash. (and reboot over and over, relays clicking over and over too. or will cause engine misfire.)

If you are not sure, what Cap. to replace?, then only replace just 1 , the one to pick is the biggest one near the Main Power input connector., in the corner.

This is the one that is always a perfect cylinder shape , and has plastic wrapped over metal aluminum. SEE C111 Below on 8V ECU.

It will be marked similar, as the below shown Caps. EG: 100uf @ 50v or 63v is typical. Your circuit ID’s may be different. or 50uf , just read the side.

Find a replacement, that is the same value and with the lowest ESR and the highest temperature rating. See Parts section below.

Do not replace the bright colored plastic looking gum drop caps or flat disc caps. They will be fine, just replace the Black Piston shaped cylinders ones.!

Doing this one step , is the best thing you can do for your old 89-95 ECU. The 1989 ECU looks like this.

Lets replace the one CAP? Read on.

The ECU is designed to last 20 Years or more, but the CAP.s (cheaper) are NOT. They are the weakest link in the chain. There ARE better caps made for sure.!!!

(aka: ECU, ECM, PCM, Engine EFI control Unit, or fuel injection processor /controller, or power train control module (modern SAE name))

Can’t wait?, then:

Click here for ECU removal instructions.

YOU ARE HERE BECAUSE?:

The CEL lamp is dead and the Fuse ALL 3 ARE GOOD.?

The ECU power pins are not dead?

Spark dead. Fuel injectors all dead and spark dead?

The ECU +5vdc refr. pin is Dead? (seen easiest, at the TPS pin)

The ECU is causing all my VSV solenoids or fuel pump realy to chatter, click madly?

You are here because all else IS GOOD so it must be the ECU is bad?

- Good motor good compression, good vacuum readings at the Plenum.

- Good static spark and is timed right?. Correct firing order on spark plugs not crossed over. (The ECU can not tell that you timed it wrong, not at all)

- Dynamic spark is good, and the strobe light advances off scale, over 3000 RPM. (if not , ECU is in limphome.) If spark is dead make sure the CMP sensor is working.

- Injectors were checked fully and are not bad, in any ways. (not leaking, not clogged, not dead, not open coils)

- The sensors all pass the tests shown here or here or look good on the scan tool.

- The ECU fails one of the 8 tests seen here.

- The car loves to have fuel pump shorted (very old pump) or the wires feed it shorted, and this overloads the ECU power feeds, causing the ECU to rest (reboot) over and over, like mad.

The most common failures, are:

These are the top fails and by no means , a full list.

-

-

- ECU Fuses blew?, (IG-coil or FI) and is because of the next item bad. and the CEL lamp is DEAD KEY ON.

- The electrolytic Capacitors dry out, leak and fail, causing the Brain to go crazy. This boric acid leaking eats up the copper TRACES, causing internal power loss. 89-95′ only.

- The injector transistors burn up , usually because someone hot wired the Injector (TBI), or by natural causes. Injectors are 1.2 ohms and are Pulse Width Modulated to keep them cool. The ECU will be destroyed or the Injectors by this practice. The Injector wires can NOT be GROUNDED out on the 8v or shorted to 12vdc on the 16v. Stop the inane practice of hot wiring EFI system parts.

- Any of the other up to 10 drivers blown up, that operated any solenoid device or relay.

Check the +5vdc ref pin for dead. The ECU must produce this voltage reference or it is bad or something is grounding it out. If 5.0v is not within 1/4 volt of perfect, the MAP and the TPS will be INOP (or grossly inaccurate). Test with keyon, if it fails , pull the MAP and TPS connectors and retest, if it passes then one of the two sensors [MAP/TPS] (or the wires) are grounding out this critical reference voltage. This voltage is infamous for dropping to zero due to a trace burning up in side the unit. (easy fix ). If you get a +5vdc failure you will see lots of DTCs for sure.

-

It goes without saying , that anything can happen, on such a complex board, but the above items, are very common. 1000s of transistor and connections.

If a good CEL lamp is out key on, the ECU is dead if the main relay still pulls in.’ (lamp good and power to lamp good)

The main relay must be active at all times keyon.

All failures above are usually, caused by outputs shorted in the harness or objects under control , except #1.

Look for shorted injector, solenoids and relay.

Not to mention lightning hits, floods or owners hot wiring pins to the ECU.

TAKE THE BASIC ECU 8 to 10 TESTS , all EFI years

1996 and newer cars too, but you need to use the newer DTC error codes for 1996+.

These test are for Catashopic ECU dead only, these early years love to fail, here… and thus my section here…

This is only a very simple test set, nothing fancy. In no way, is this an extensive test plan. Not at all. (the ECU is complex)

( First, be sure all fuses above the left knee fuse box are good, FI , IG-COIL and DOME fuses, must be not blown out)

On 96+ cars some fuses moved to the right front inside fender main fuse box. (see operators guide or my electric pages ,back one page)

If the CEL (aka: SES or MIL) lamp is good ?(not burned out?) .

Rules:

The ECU Fuses must be good, the 5vdc ref pin must read near 5vdc, at TPS. (4.75 to 5.25vdc is SPEC.)

The CEL must glow keyon or the ECU fuse are blown or ECU is dead, or the lamp is burned out , FIND OUT WHY FIRST !

The 89-95 car (USA) must flash DTC CODE 12 OR OTHERS ON DAMAND OR THE ECU IS BAD. (or on later years, outside usa)

The 96 and newer cars, (USA) all most show scan tool data , on demand using any scan tool. (see TPS data, ECT, live data and show CEL is on or off)

Do not run Rubycon Cap’s in any ECU, get them out while ECU IS NOT ACID WRECKED NOW.

All ECU tests below are CATATSTOPIC fails. ALL ECU’s made, can do this…

ECU Test 1: (KEY ON , DO NOT START engine, LAMP TEST)

Keyon. the Check engine lamp CEL must glow, it MUST glow! (aka MIL, and SES lamp)

IF NOT? ( fix this first) (in 1996+ we can ignore the silly lamp and use a scan tool to see all DTC and the MIL/CEL status at any time)

- ECU is dead. (this page below covers that, fully) The ECU has power ! It must or it can’t glow the CEL.

- The CEL lamp is missing (a rotten Prev.owner fooling the smog man? removed it.?) or the lamp simply burned out. Or black taped over?

- A Dead ECUs may not light the CEL, this is a common See my end zone for all the ways…

- The ECU that failed and dropped to BACKUP mode (a unique mode explained in the FSM) the CEL goes DEAD. (motor may run barely, lots of black smoke out tail pipe.)

- Main Relay is dead, or someone hot wired the Fuel Pump relay slipped and blew up the main relay ECU diode, on 8V pin B15 (Green connector) or 16v A10 (D102)

The ECU can enter failsafe or backup mode ( a dead ECU or inputs bad to ECU) In Failsafe mode, the CEL may work. but in backup mode CEL, may be dead.

” Engine is stuck in Limp Home mode, “Fail Safe” it is called by Suzuki” ( Black smoke, low power, horrid MPG, RPM limit, retarded spark)

One way to get Limphome is to unplug the MAF (16v) or the MAP (8v). BAM , failsafe !

Assuming all the fuses are good and the MAIN relay is pulled in and full power is applied to the ECU. ( check it)

The ECU only has a single diode to pull in MAIN Relay. Do no hot wire main relay or risk blowing this ECU diode up. (on cars outside USA the IMMO may control this relay) (immobilizer)

ECU Test 2: ( Commanding up Trouble CODES Test) Inseart the Diagnostic jumper seen here.

YOU MUST GET SOME Flashing code. 1989 to 1995) code 12 or some other code or the ECU IS DEAD!

The main front engine bay DLC is the Diagnostic Logic Connector for the ECU , not TCM.

Insert the Diagnostic Jumper (89-95) in to the DLC Diagnostic pins of the proper plug. (keeps moving year by year)

Key on , Do not start engine. CEL glows now.

Steps:

- The Diagnostic request jumper is inserted. (paper clip) 1989 to 1995, see end for 1996+ cars, 1996 have OBD2 and no jumpers.

- Federal body cars, the FEDERAL NAG lamp switch must not be in NAG mode, that is CEL stuck on, no matter way. (mileage nag) I defeat all NAG switches !!

- The ECU will now flash code 12 or some other code, if it does not the ECU is dead. (89-95 only)

- The ECU must flash something, in fact it must not ever flash 1/2 a code, it must be consistant or the ECU is bad. (bad caps (etc) cause, aborted, code flashes !!!!) (89-95 only)

- IF a 1996+ car, plug in the scan tool and see that you have communications, if not, the ECU is DEAD. DLC pin 16 dome fuse is blown. See tests here.

- For all newer cars, the test here (1996+) is does the ECU communicate with the scan tool.

The engine don’t start and run?

ECU Test 3: TACHO test: No starts? No spark? or no Injection?

If the ECU is Thowing code 42, there will be no spark. 92 to 95′. P03xx on 96’+

If the 1989/90 Distributor is dead, there will be no tach signal.

This test is not for ECU, it is to see if the brown tach wire is dead, if dead the ECU will cut all fuel.

I use a scope to do this, but with no scope, we are reduced to dash gauge hope.

Some 2wd cars have no Tach. So make sure , ECU does not throw, code 41 cranking.

The dash Tachometer must move up scale cranking, if not?, the spark is dead or the tacho feed is bad. (the needle just moves a very tiny bit here, 0.2 rpm is tiny (200)

( if the battery is weak, this, makes the tach dead or weaker, cranking or the tacho on many old Sidekick is just dead, from age)

If the ECU (pre 96′) throwns no Code 41 just makesure RPM looks good on 1996 cars, then the tacho meter signal is good.

The Tachometer moves at all its good,

On a 1996 car, the scan tool does not show P0355 or 340 or 300s (bad spark or CMP/CKP sensors) and the Scan tools shows RPM Dead, as you crank.

- Keyon (not cranking) (2 digit DTC codes are 89-95 only)

- The 89-95 Diagnostic request jumper, is inserted.

- 12 DTC code is flashing?, (if other codes flash (correct the causes stored), then clear them, with DOME fuse pull and put it back )

- 12s flashing ,you then crank engine over 3-10 seconds, no more , no less. (some manuals list 6 sequential fails cause 41) I do 10 seconds,! (89-95 only)

- Release the key do not turn the key off. Look at the CEL lamp flashes , now? 41, or 42? (or use the scan tool and look for problems or DTCS)

- You do not get code 41 or 42 ( the 2 kinds of ignition failure spark fail or CMP failures.) 89-95 only.

- If a newer 96+ car, make sure you have communications, no DTC 1600 , and that you can see the TPS move up scale as you depress the accel. pedal.

- 96+ the RPM PID ,moves upscale as you crank. All 1996+ cars ,even new cars, all see bad CMP, CKP or dead RPM cranking, if those sensors fail. (all cars EFI)

Key off, if 12s flash out, now. (or the 96+ car passes all tests for TPS, and other sensors reading normal, say the ECT reads room temp)

ECU Test 4: If engine will not start, skip this test #4 and go to test 5.

- After starting car the CEL must go out, if not, it has stored codes, use the diagnostic jumper to find them. (89-95 only)

- If CEL not out? the NAG mileage feature is active. Kill the NAG and repeat this test. (89-95 only)

- The dome fuse pulled , resets the ECU but not the NAG feature, only the NAG switch can reset NAG feature.(89-95 only)

- NAG, is the mileage exceeded feature. Found on all 89-95 USA only Federal body cars.(89-95 only)

- If the NAG is defeated and the ECU will not show 12’s or some other code or the lamp going out! The ECU is bad.(89-95 only)

- The lamp going out is normal that means no stored codes. or no live failure codes.

- Starting (no pun) the 1996+ and newer cars there are no flash codes.(no 12s) You must use a scan tool and check all sensors and DTC’s stored with said tool and check for errors. Any modern scan tool can scan any 1996 and newer Suzuki.

ECU Test 5: Rapid relays clicking (repeats constantly, key on?) (89-95 only, do this nasty trick)

If the cars battery is discharged down to 10v, why are you here?, and fixing THAT problem

The ECU don’t run on 9.9v. sorry!

The fuel pump and run ok, but be shorted, not drawing 4 amps but draws say, 10 or more amps, this overloads, the ECU power buss (weak copper)

and the ECU boots over and over, (crashes). This is a pump with one shorted armeture segment where others are good and working.

This can be seen with a scope on all cars doing this

The ECU caps are bad, allowing the inputs to internal regulators to go crazy, causing reboot of the firmware.,over and over.

- If relays and VSV, don’t chatter, go to test 6.

- Repeated clicking actuators, Relays, and VSV valves on front of engine? or under the dash ?

- Top cause, bad main Cap.s in ECU , or shorted ISC , shorted fuel pump, or acid damage inside ECU.

- YES, an overloaded (4amps is norm) Fuel pump IN FACT overloads the ECU power buss, causing it to Reboot over and CLICK madly.

- I have personally seen a pump sucking 10amps current do that. and a huge voltage drop on tiny Sidekick wiring…to the pump and ECU.

- Try unplugging the fuel pump or its relay to see if the noise stops.

ECU Test 6: (can the ECU actually see errors and report them test?)

The DTCs can show up, just keyon and some only cranking. (just unplug a sensor and crank , bingo)

- Unplug the ECT sensor ( start car for few minutes, and see if CEL lamp glows.) (same with cars with IAT)

- Most cars can see an open ECT sensor, even just key on. (all mine can)

- Then place the DLC Diagnostic jumper and see if you get code 14. (89-95 only) (use a scan tool in 1996+ cars P0118))

- If no 14 DTC error code, the ECU is dead. (P0118 in 1996+ cars, use a scan tool)

- You can do this test just key on and not running, unplug IAT and or, ECT and you must get a matching DTC, LIVE.

- or the ECU is bad. Those 2 sensors going to infinity is detected in about 1 second flat.

- The IAT is on the air cleaner on the 16v , but is on the right lower side of 8v intake manifolds. see maps here.

- The IAT is a very safe sensor to unplug, so is ECT (it’s locked do not force it !!) they are not sold the connectors.

- The 1992/93 16v engine has no IAT, and odd fact. – 58B30 ECU p/n (use ECT as the test here)

- Most cars when you key on, the ECU scans for dead sensors. 1st thing. Catastrophic monitors tests.

ECU Test 7: No Start’s (is the NOID lamp DEAD? a $1 lamp can answer this)

The ECU can go dead, or an injector driver can go dead. (spark must be good)

No one knows what NOID means, how about, NO Injection Drive, (good huh?)

We use then Noid in place of the injector to see if the ECU is driving injection signals, that is IT.

The NOID test, proves the ECU injector driver is dead, ?, it’s a transistor inside the ECU.

The NOID lamp connected to each injector, 1 by 1 MPI, or just 1 injector seen on TBI 8v engines.

You crank the engine and the NOID flashes, it must not be dead, nor stuck on ,just key on.

Or the ECU IS BAD. (harness shorts, on those 2 wires?)

If the NOID don’t flash or glow cranking ?, then the ECU drivers are bad. (or there wires cut or grounded out)

If one NOID test fails that driver is bad, if all NOID tests fail, x4, then the ECU

is bad or there are codes showing why?

Exceptions: ECU normally cuts all injections for: (fire Safety per 6 ways below: )

- ECU sees bad spark (code 41) newer 96+ cars , use dead RPM,.or DTC P0340 ,355 any 3xx errors. hard fail.

- ECU sees bad CMP ,(code 42) 1996+ P0340 , dead CMP kills spark and dead spark kills injection , by design.

- ECU sees its self dead, (CEL goes dead) it can do go failsafe or backup mode, and may just flood, see DTC errors for why. The ECu can be born dead. (power inside lost)

- IF ECU sees wide open throttle all the time (or ground wire to TPS is open)”unflood mode by accident” or TP (TPS pin) stuck above 3.5vdc. (wide open throttle)

- ECU lost power to ECU, or lost 12vdc power to injector connnectors. Fuses. or bad wire and connections?

- Outside, USA the IMMO can kill injection. The immoblizers does just that, it shuts down the ECU. (by design) outside USA feature.

If any tests don’t work right, pull the Dome fuse for 2-5 minutes and put it back resetting the ECU memory page, and repeat the tests.

On 1996+ cars, the scan tool is used to clear all DTCs stored, and is best practice, but sure,the DOOM fuse resets all DTCs on all cars of this brand.

See my list of all ECU fails here.

ECU Test 8 : NO COMMS checks: USA. (Other countries run OBD1 out to 2001 year )

The 1996+ cars (USA) a dead scan tool is a dead ECU Or fuse blown, Main relay dead, or pin 16 on the DLC is dead (A FUSE)

There are no over the counter scan tools for pre 1996 Suzuki’s (or Trackers) (what is OBD?)

(Autozone can’t do pre 1996 Sidekick or Trackers with OBD1 ) please don’t waste your time, or fuel driving there.

Suzuki does not document pre 96 commications protocols or disclose them to any one. Ergo, no scan tools. Sucks huh?

Attach a scan tool , key on, and if the scan tool , can not communicate?, with the ECU , the ECU is Dead. (or pin 16 in the DLC is dead, no 12v, a blown fuse.)

Pre – 1996 Suzuki’s: (OBD1)

The 1989 to 1995 cars, a DEAD CEL lamp is a COMM fail. If the lamp is good, it must work ,if not the ECU is in BACKUP mode or DEAD.;

Do not forget, you can drive all day with the Diagnostic jumper inserted to find intermittant problems. (89-95 only)

In 1996+ you do this with a full OBD2 scan tool and with a logger active. You can log for days, any parameters you wish called (PIDS)

The OBD1 ECU might stop flashing (89-95 only) code 12s and stall or stop flashing mid flash (that is ECU crashing, bad CAPS , mostly)

ECU acting odd this way, is a bad ECU, and has bad CAPs. See how to buy em’.

The diagnostic mode jumper (OBD1) does not hurt the ECU nor interfere with its operational status. It’s 100% safe to use.

Do not drive with the timing freeze jumper planted. (you will melt the CAT) In 1996 they added a DTC warning you , that you made this error.

Starting in 1996 there is no diagnostic jumpers, forever.(TCM excepted) OBD2 ends that, practice in the USA. A SCAN tool is about $9 today (2013)

In 1997 the TCM was merged in to the ECU and renamed PCM.

ECU Test 9: Get your ECU tested?

(ask CARDONE?) A near endless lists of tests and top ISO 9001 QA checks. No joke.

Keep in mind true testing, is complex. (done at low and high power voltages, done HOT and COLD, and with vibration) and all features tested, not just engine runs.

Cardone does a “send it in for repair” , service, R&R, repair and Return, CALL them.

Most major autostores here in USA, sell CARDONE rebuilts.

Here are the 4 choices , (skipping my DIY above ) see them here.

Finding used, ECU that are good, is very very hard and every day will get worse. (age) Watch out for scalping on Fleabay.

Check out CARDONES, help on common electronics problems.

Test 10? is not to condemn good ECU’s unless? (do not skip this page)

SPARK?

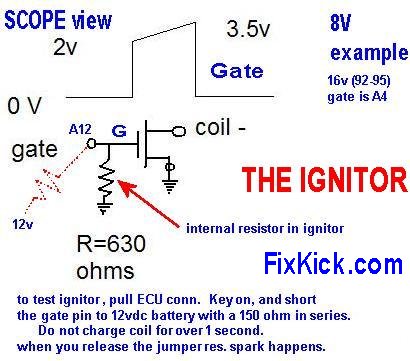

If spark is bad (at coil) and no errors from the ECU and the ignitor input is good, then the ignitor is bad or the ignition coil is bad.

The Ignitor INPUT signal looks like this (cmp and ckp good).

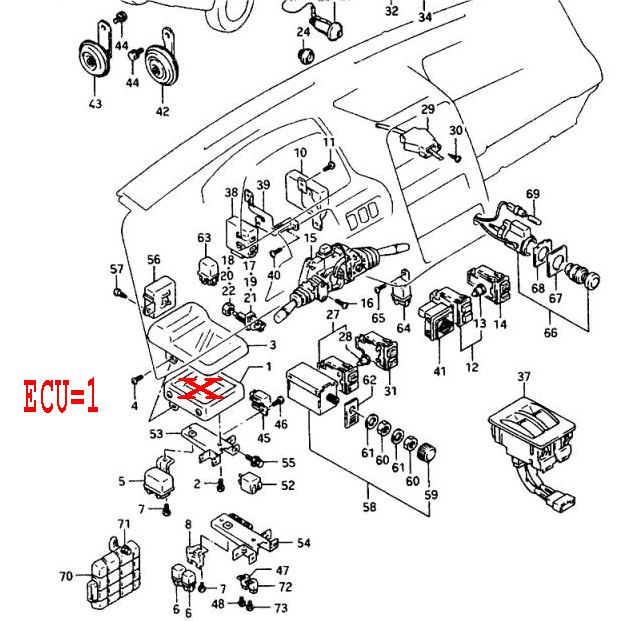

Removal of ECU: 89-95 . (in 1996 the ECUs is still here X, but main and FP relays were moved to right side heater case)

I can remove ECU in 10 mins now. (or less)

Steps 1, 9.

On one car, the 2 Phililps head (binder) screws are very very tight, so I had to remove the whole mount. (then got them out on a bench vise, and replaced them with real screws , hex head)

Use a number #3 Phillips large screw driver, at the front screw and rear 2 screws. (this is the only hard part)ECU: removal: (left hand drive cars). { ALL SUZUKI connectors are locked, Never ever force them, depress the lock lever and wiggle gently)

- Disconnect battery neg. terminal, black color. so you don’t deploy air bags (many cars have them ,maybe not yours) and you dont blow up ECU, if pins cross because that is a real risk. Air bags can be lethal. Most USA cars this year range have no Air Bags, but other markets might. I do not know .

- Remove speaker left front, cover with 4 screws. This 3 steps are NOT necessary, it’s only for folks to see it , easy, if getting under dash is hard for you (large people , ways) or to view TAGS!

- Remove speaker and unplug it. (optional)

- Look inside speaker hole, see ECU?(optional)

- If you are skinny, look under the dash. See number 1 below? bingo.

- If you are big person, removing the front seat is easy (4 bolts) and very helpful. That is MY way. (with blanket on floor boards to protect your spine)

- Some can remove the connectors on ECU now, but the Connectors have locks are on top. if not easy to unlock now, skip this step until later.

- From the bottom remove the 2 Phillips screws (size#3), on ECU front and rear, that have there heads pointing down. (can be real hard to remove)

- The screws can be tight and you may need to remove the whole mount, Later,I replaced the 2 bottom centerline screws with NORMAL ISO 10m hex head screws,(6mm threads)

- Slide ECU to the front of car (firewall). (loosen wire ties or remove them as necessary.

- Next ! , depress the connectors locks and wiggle out the connectors on the rear of ECU, one white and 1 green on 8v. DO NOT FORCE any conn. locks on this car, they are not SOLD.

- ECU is now free. remove it.

- To put back ECU, reverse the above.

This drawing below should make it very clear as to the location. (on some cars I had to remove the ECU mount #53 first. the 2 philips took bench work to remove.)

Part I’d 3 is a rain cover (for driving with broken windshield) Missing on many cars, due to poor service.

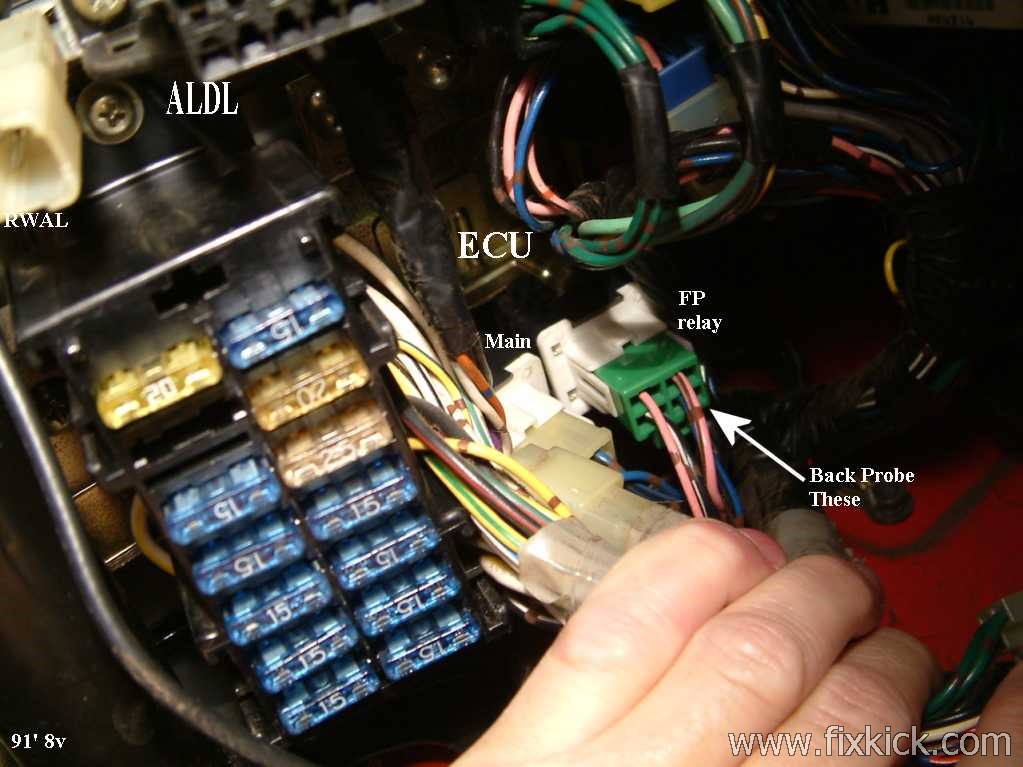

1991 M/T car is shown below (89-95 similar) The Pink wires are Fuel Pump Relay , on Green socket, Main Relay is to the left.

Back probe these for lost power to fuel pump. FP.

![]() Eg. 8v 56Bxx ECU.

Eg. 8v 56Bxx ECU.

Driver Transistors are easy to find and buy.

A dead injector? that you found, and the NOID TEST FAILS?, ( and no DTC 41/42 or P0340 or 355s with the scan tool?)

Never condemn lost injection to an ECU, if the TPS TP pin is stuck high. (or the brown Tachmeter line is dead, “for any reason”

Never condemn it for Code 41 , 42, or P0340s, 355s’ etc. (same with dead power pins to ECU)

That logic state W.O.T is a feature, and is called unflood mode, and the injectors are, in cut fuel state. WOT = wide open Throttle or TPs is stuck high.

Ok all inputs are good to ECU so …

You then want to replace the driver transistor(s). Seen in my photos of ECU.

Where to get parts?: Digikey, Mouser , or MCM are the top 3 sources here in the USA. Mouser ships Cap.’s lightening fast (all parts).

Transistor?:

The below are back up sources for hard to find transistors only.

Source 1: My favorite MCM electronics (they don’t have both transistors only 1)

Alt Source 2: Match a Knob in NY , has both transistors for the injectors. , min. order is 2 (they do have both transistor)

MatchKnob B1020 in New York.

Source 3: Electronix.com , 1 Herald Square, Fairborn, OH 45324

EBAY: But avoid China and HongKong. (a long trip and lots of down time… B1020 – example here.) but is viable, for the hard to find parts.

Again. Use GOOGLE, and search by P/N. like 2SB1020. Finding parts, is a skill and changes weekly, as suppliers dry up or add up..

CAP SPEC’s (the aluminum tiny garbage can looking CAPS. cylinders they are) (new)

I get all my cap’s from MOUSER, they ship Lightning fast (automated it is) ! or from Digikey. (IN THE USA!)

Here is what I buy, I buy Nichicon Cap.’s from Mouser using Nichicons best Low ESR product for radial leads.

This product is called UPW series. Buy only Radial Caps or Axial CAPS if desperate. (bend leads to fit latter) Desperate is not a bad word, stuff happens…/???

The UPJ (old UPF) is long life cap, and is 13 cents ! (The cheap price, reflects huge popularity , vast numbers made, do not let price guide you, Nichicon is fantastic.)

I do not know the radial pitch on Suzuki PCB (distance between leads, 2.5mm or 3.5mm) measure it. Or bend the leads to fit.

Cost? 13- 50 cents/ea.

Here is the most common cap to fail (pre 1996 cars) is high temperature rated use 56uf/63vdc. See it here @ mouser (the origional might be 50uf and volts 50v)

If you need Differant uF cap, use the same Mouser charts for 105°C rated caps by same maker , Nichicon. (btw, mouser ships real fast. lightning fast (click Instock box, first)

Pick list:

- LOW ESR or Low impedance (both mean the same) Nichicon UPJ is the best. (IMO) (impedance , is A.C resistance)

- Higher voltage is ok, , 47uf is same as 50uf. ( if you go too high in volts, the top of cap may hit the ECU lid, so be careful)

- Highest range of temperature, is the most important in cars. -55 to +105C is best . A car cab ,can infact hit near 90C ! So hot ,you can’t touch the steering wheel. Fact.

- Highest load life. 2000 , 3000, and up to 8000 hours are possible.

- In stock.

- Nichicon UPW series are good and UPJ better, I like them. Lejon is good too. RXA series.

Low ESR is a critical factor in modern ECU/PCM/TCM’s

In fact, I bet you the origianal caps in 1989 were not low ESR Cap.’s !

My one example works above, for the other caps, that have leaked, or are marked Rubycon. (originals are known bad)

1996 + cars, the caps never fail.

Just get the same series caps (PUJ), from Nichicon, series, or UPW, per your uF and volts .

The leaks are acids., Glycol Borate? based, I tell you that, to make clean up more easy. (Bicarb cleaned) or Boric acid based.;

WHERE TO GET NEW CAPACITORS ? << click me.!

Electrolytic Cap.’s are far from equal, see over 30 formula’s here.

Buy top brand name parts and stick with them.

Parting shot?, if you find a cap below 50volts, try this solid polymer cap. (can’t dry out or leak)

See guide lines and limits to Electrolytic caps here.

Caps can fail many ways, they can dry out (0 uf?) bulge, crack, split,warp, distort, leak, burst or explode. (even get dented)

See this direct PDF page 17-25 to see failure modes , also linked below.

See the this page, and the link there marked, Extended Lifetime , if serious about quality and life. This is one of the web sites on topic.

ESD Warnings: ElectroStatic Discharge , damage 1a:

MOS Transistor based components are here. (IC’s or as many say, chips , which means nothing in and SMD world.)

AVOID Excess or HANDLING DAMAGE ( don’t touch pins or circuits unless replacing parts)

ESD?, ever touch a door knob?, on a cold fronzen winter day and see a spark? , that is an ESD event !, 10 times less, unseen, will kill some semiconductor electronics.

Even nice days when there is no felt or seen ESD sparks , there are ESD events. (less for sure, but still present)

OLD electronics parts and systems are far worse for ESD, some parts have zero protection inside. (we called it naked MOS, back then.. yes , I’m older than dirt… )

If curious? Read forever here at the WIKI

The reasons for most static problems causes and the Triboelectric effect.(advanced readers)

Be sure to handle your ECU carefully (even the FSM has warnings) and to observe ALL Electro-static discharge procedures. (ESD )

( DIY in a pinch)

ESD protection has NO LIMITS, (I’ve worked and built labs to these spec.’s)

A full ESD works station and carbon tiled floor , chair, clothing ( carbon threaded smocks) shoe straps, wrist straps, and carbon plastic tools .etc.

$10,000 easy to spend, even on special benches and with the mat.

Many smart shops just use a 3M desk carbon mat and the 3M strap.

The costs are near unlimited ,with climat controls ,etc… (yes, 0 percent humidity is a chip killer)

Do your best, don’t let my page, scare you or render you helpless, as do ” F.U.D mongers”, love to do.

Just do it. Imagine yourself saving $500 bucks !

What’s there to lose? a $50 core? (it’s dead already?) ( I buy 3 cores, and put in new caps and now ready for anything)

A professional shop has a 3M grounded desk pad, a 3M wrist ground strap, an anti static chair seat and back (carbon fibers) ,floor tile with carbon.

A pro grade carbon fiber based , solder sucker. (black carbon case) , and all other applied tools containing plastic are carbon based.

(this is repeated in 1000 of Major FSM’s (factory service manuals) of all makers of cars)

The soldering iron needs to be one, with a 3 wire AC line and the tip must be grounded. (no 2 wire soldering tools)

DIY car repair solutions:

- Wear a wrist Ground strap (resistor built in type) at all times working on electronics of any kind.

- Use a straps, even removing the ECU (TCM , PCM, etc) from the car . (in our shop we have wrist straps and foot straps)

- Do not wear plastic clothing, use cotton jeans. The human body generates free electrons, plastic can make 1000 times more force

- Do not touch the PCB connectors, use only a scope or meter to touch them , not your hands.

- If you must repair the PCB, use the strap and ground it to the ECU ground pins.

- If you take it to a shop, make sure they are ESD aware. (look for strap usage and ESD mats on desks)

- At the least use a metal top bench, better is the 3M carbon mat is vastly better, do to RESISTANCE. ( I use this mat)

- The best setup is the person is a carbon resistance to ground and the bench pad , the same. This fact reduces , the total zap currents to nill.

- Keep new parts in a static safe bag (many are tinted pink) until ready to use. For IC’s and semiconductors we use carbon foam pads.

- Do the best you can and be happy, Do the work and try not to get ham strung, to total uselessness, due to all the above.

- At the end play , some one must repair it. But ESD, is real and needs to be addressed.

- Our shop (pro) has $10,000 in ESD equip. , and carbon tile floor, desk, seats, and bench tops and people with carbon in the clothing. FACT !

- See Scanning Electronic Mmicroscope SEM photos of parts our customers blew up!

- “Nothing ventured, nothing gained”, and ESD is like safe sex, the only safe sex, is no sex at all…

- In the early naïveté days late 1970’s, of MOS and CMOS, many devices, the MOS gates were totally unprotected.

- Newer parts 2001 sold are vastly more protected , This document shows how modern computer ports are protected 2012.

Use a wrist Strap clipped to a ground.

This “Van De Graaff Genererator” in physics lab shows how static charge moves. This drawing is brilliant.!

The damage happens , at both end of the spark. !

Did you know, the first weapons grade Uranium was made, with the above device? but LARGER (read this fine book)

This topic, ESD ? , is an endless topic. (end ESD.)

HOW to tell if my ECU is factory virgin or has been rebuilt?

1: Evidence of shop soldering methods (not factory wave or vapor phase reflow soldering ) Hand soldering looks very unique.

2: Warranty stickers sealing !the case. “Joe’s ECU rebuilders , LLC) < I made that up. Or here is a real one, “CARDONE.” lots more companies exist.

3: The Conformal coating in bottom or top was breached by hand soldering. (flux found on pads?)

4: Acid damage obviously corrected, I use litmus strips to detect for, “is that spill acid or not?”,I can tell if the last tech corrected, that spill.

5: Non Rubycon caps , (all or part) some ECU do have non Ruby caps, in the center section, but ruby in corners. Replace all found Rubycons.

6: Cap’s with blowout crosses on top ( this in non 89-95 caps) the cross top says to you , NEW CAP. (Old caps blow out acid via bottom rubber plugs (bad practices then and now)

7: Evidence of the black soot on lid, someone tried to clean, it but didn’t get it all off, obvious to any tech.

8: Corrected burn up damage, a transistor was replaced and the old burn mark soot in till on heat sink or on PCB. “Signs?”

It takes seeing a virgin ECU to detect changes. 1 time. (virgin is, OEM factory stock and unmolested)

So, not knowing what is normal, makes it hard for people to discover differences, No?

A trained tech knows what is normal in a generic sense. But experience ,tells us what parts are non OEM.

NOW , how to replace the main CAP: eg;: C111 (or equiv) ? LONG PLAY:

Any TV electronics true repair shop can do this. (not shops that only know how swap boards, we call them board swappers)

(Arcade game repair shop, home electronics repair shop, ham radio nut “all old Hams can solder ! very well !, and lots of true GEEKS but not geeksquad.)

I can not teach soldering , (can in person) but not in text form , so I will not try , but I can list the steps. One liners !

- Pull ECU out , see above instructions.( disconnect battery minus cable first)

- ESD protected table and person. Use a fan to blow the smoke and lead fumes away from your work station. (and others)

- Take ECU Lid off , Remove the 4 screws on sides of ECU.

- Look for smoke stains under lid ! Not good! Carbon smoke on lid ,underside ?

- Look at each CAP and for Acid damage below it ! (electrolyte leakage, it is called)

- Remove the 4 corner PCB screws. Printed circuit board.

- See heat sink? On drawing 2 , remove 2 screws at each end. The main PCB is now free.

- Lift out PCB , keep left hand on metal case , never put PCB on plastic of any non ESD rated, kind (Use anti static procedures)

- Using solder wick , wick the solder from the bottom of C111 pads, or use a solder sucker. ($5 tools) A solder sucker tool, excels at this.

- Use a grounded tip soldering pencil (30watts or so) (or a 100w soldering station set to 700F) Both have a 3 prong power plug.

- Remove solder (sucker), then wiggle the pins until they are free of the PCB pads and VIA’s, then pull it ,the CAP noting the alignment of the MINUS STRIPE on the CAP side.

- Clean up any acid found under the Cap with backing soda and water mix. (I use a bottle cap, water and Bicarb mix and use a Q-tip)

- Repair any trace damage at this local area, look carefully for damage ! to the traces ! DO NOT DRILL HOLES in the PCB !

- Put in a new CAP in same spot and get the Minus Stripe back to the correct orientation (polarity) Plus mark to non stripe side, and stripe side to minus mark (earth)

- Solder it back with 60/40 Tin lead solder , no acid core , only rosin core. “electronics only solder”

- Clean flux with alcohol , and then Reverse all above removal instructions.

- The board has lead, so using non lead solder is not important, as its already full of lead, Do wash your hands before eating food.

- Touching lead is safe but eating it, big time ERROR. Do not rub eyes or smoke CIGS while sholdering.

- The PCB is conformal coated and this is normal, you must scrape off the coating to solder most joints.

ESD?: NO OCD, no paranoia, no sleepless nights, (LOL)

In a pinch, lay the PCB (ECU) on some Kitchen Aluminum foil. and keep it there. A DIY , anti static work station.

A key fact on ESD, if you don’t build a charge, there is nothing to bleed off. Prevention is #1

The best work station, is a huge brick of carbon. unlikely to find that , expect used, from the Hanford Nuke site.( just joking around, the later)

Carbon bleeds off the static charge, in safe manor. Most techs learn, to keep one hand on ground trick, working on ALL electronics. even swapping PC cards.

At the minimum use a ground strap , clipped to the PCB ground screw. (corners)

Avoid plastic top tables like the Plague, and if your shop is 0% humidity, take super big time care.

Seems hard? ,but it is a 1 hour job.

I can remove ECU in 10 mins now. (2nd time, is way easier) Use a number 3 Phillips large screw driver, or you will fail. (throw old screws away and use Hex head screws! M6

End:

A common Question: FAQ

I get asked this over and over , so here are my answers:

Do the other non electrolytic caps go bad?, NO. Do not touch the ceramic disc, or gum drop Tantalum Caps.

If the acid eats up a ceramic cap “SMD” below the main Electro cap , then get a new cap with 0.1Uf 50v and replace it. even a ceramic cap with leads will work.

SMD means Surface mounted Device, as compared to old school, Through Hole Devices (aka; radial leads, on relic caps)

There are no internal schematics for ECU’s ,nor have I seen any or heard of any, but I have one for the Injectors as listed above.

I have a schematic for injectors drivers, and all +5vRef circuits. See some schematics Drivers . Outputs can blow up. Inputs do not. As a rule.

So, if any output goes bad, you now have the transistor location and P/N. (part number)

Just replace the transistor by function that is failing.

I have car and engine electrical schematics, that are right here.

I also made up a ECU part number list.

Fast facts on repairs: (do’s and don’t)

Q: can all ECU’s be fixed?

Not all ECU’s are repairable. (not all parts in the PCB are made today , nor stocked ! Keep that in mind when things don’t work out…

There is no limits to damage, the worst is lightning damage, or and alternator that went to 30vdc. (went nuts)

If the processor blows up or CAP ACID burns a huge hole through the board ,or the acid burns and the PCB carbonizes it, then she my be END OF LIFE.

An end of life ECU is just like an old rusted out car, so don’t criticize any man who can NOT do what even a Deity can not do! Please ! and thanks !

Q: Can I use just any injector driver transistor.?

Do not use metal backed heat sink driver transistors (injectors) use the all plastic package ( special suffix pn) Do use heat sink compound as appropriate to the drivers.

Q: Can I use any type solder.?

Do not use acid core solder only rosin.

Q: Are all CAPS bad? NO!

Just the Rubycons were bad. ( I’m told the new rubys are good, why would I care?, when top brands abound. Once bitten , twice shy?, how about 1000 times bitten.

I run top brand Japan made caps. I’m not saying Rubycon’s, new today are bad, I don’t know that and never will, but considering the facts here, you can figure that out easy…

I use these UPJ parts (buy the widest temperature range)

![]() A Top brand is Nichicon UPJ/UPW (a very good brand ! so is NEC (Aka: Panasonic))

A Top brand is Nichicon UPJ/UPW (a very good brand ! so is NEC (Aka: Panasonic))

If the caps are not black plastic covered, then they may be ok. (most colored caps are great)

If the caps are marked as “RUBYcon” ,then get them out now. (black plastic wrap is the first warning…)

IF you see acid leaking, bulging , cracking , or tiny volcano’s on the caps , they are BAD. ( they can be measured easy when removed) Ask a technician. (or just swap them)

Do neutralize the acid with Arm & Hammer baking soda. Sodium Bicarb. (mix it and water in tiny cup and brush it on)

Do correct any acid damage to the traces near the caps, with jumper bridges of 20 gage wire . (scrape off the coatings, tin the copper, and bridge it)

Q: Can I solder the Electro…CAP in , just any old way? NO.

Do put the caps back in , using the same polarity as the original or as the silk screen marks clearly show. ( if acid killed the silk screen marks make your own)

Do Clean off your solder rosin with alcohol after you are done, avoid alcohol else where’s as the board is conformal coated top and bottom, looks like shellac.

That sounds contradictory, but is not, clean the pads soldered fresh with alcohol, and not the whole PCB, because the confromal will melt.(or get funky, mine gets mikly and ugly).

Q: Are all transistors the same, NO. Use the Correct Part Number and Package CODES ! These parts are PLASTIC coded.

Sadly, each maker uses different codes for the plastic type. The most populuar is dash “P” but is not an industry standard.

Do make sure your new transistors have the same Pin ID’s E, B,and C. (D,S,G) check the data sheet carefully, or even use a transistor checker to be sure.

Transistor test shows [low beta {HFE} that means it has reversal , E<>C ,emitter to collector reversal ]

Transistors come in different packages, and pin locations.!

The injector drivers are Darlingons. ( that needs extra voltage to forward bias the B/E junctions. (1.4v or more)

Do not use metal backed transistors,for all plastic type. (yes, it can be done, but takes mica kits and lots of patience with metal backed To-220 cases)

Q: How do I replace this CAP? Answer : http://www.afrotechmods.com/groovy/capacitor_replacement/capacitor_replacement.htm

Q: Is there a full schematic for my ECU, Answer: NO. ( but I do all outputs and internal power supplies, as seen here.)

I do show all drivers in each board , shown under each generational ECU in the main index. See “Full Details” in top index of this page.

The driver transistor exact locations are shown in each section of each ECU, generation, for 8v , 16v. See Menu items 17 to 21 above.

Q: Why do I say some parts are Unobtainium , Answer1: they are NO LONGER MADE, or need secret programming .

Answer 2: sure find another old ECU and cannibalized it. or use substitutions.

Q: Do I fix ECU’s for a business,

Answer :Sorry, No, not any more. I retired from working controller repairs of many kinds, even driverless train controllers and fault tolerant types., and other complex robotic systems, PLC’s and proprietary systems. This includes, Military systems. Most of which I can not even mention, and for sure, not in specifics.

Q: How can I learn to solder? easy, buy and electronics kit and practice. You can learn in a day.

CLICKING RELAYS under dash below ECU:

See my click and FI blowing page.

Things that make ECU look bad, but ECU is not bad.

- Bad 12vdc electric power feed to the ECU. (below 10vdc the ECU will go NUTS)

- Shorted Fuel Pump (normal draw is 4 Amps.)

- Shorted ISC solenoid (6 to 12ohms , 89/90 can be good at 6 Ohm’s no less)

- Shorted wiring , off ECU.

- Shorted RELAY’s , off ECU.

- Shorted VSV coils. (up to 5 on some years)

- Shorted Injector coils. (1 to 6)

- Shorted 5vdc power lines to TPS and other places.

- Shorted inputs to ECU (sensors shorted)

Never replace an ECU, until you remove your shorts. My wife slaps me, with I do that.

THE END ZONE:

All the things I have seen (and repaired) with ECU/ECM/PCM and TCM’s go bad .

Engine controllers or tranny controllers,etc.

Not just stall the engine dead, as some my think.

The ECU is not Hamster in a box with a bottle of Whiskey and a push button. LOL !

1: The ECU can go to backup mode

(a dead main ECU section and a back up chip with fixed PARAMETERs, that run a motor , in the most horrible possible way !! “BLACK CLOUD”

2: ECU goes to limphome, CEL on or off, all other facts or tests are useless you must find the cause of limphome. now. 15mph is typical.

3: ECU will not glow the CEL (lamps is present and not burned out, and all fuses are good above left knee) The ECU self test FAILED.

4: ECU glows CEL and will never turn it off , no matter what you do. ( we assume the Federal Nag switch is OFF.)

5: ECU flashes, a DTC code and mid stream, it aborts. ( ECU is crashing, bad main cap’s or a bad internal powersupply)

6: ECU will not even flash 12s, but CEL comes on. (Nag switch off , this is bad ECU)

7: Scan tool keeps, WARNING , “lost communications”.. a bad ECU.

8: Injectors cut out. (ECU is rebooting , interrupting normal injection flows) (ECU internal power loss issues, bad CAPS, loss of CMP, loss of spark cuts fuel)

10: Any ECU connected actuator output ports dead, see my transistor page (above) for that.

11: Any ECU input ports dead (very rare) inputs have very good protection on these ECU. “bullet proof , i’d say” Listed for completeness !

12: BAD caps YAH. Symptoms very ! #1 FAIL !

13: Ignition drop outs, the CMP is 100 % ok. but ECU is not ok. CMP is the CAM angle sender. CMP drops must fail for 3 seconds for ECU to report them.

14: Any of 1000s of other problems , incredibly rare…? 100,000 tranistors in all , no joke.

15: Vibration sensitive fails of any kind . Loose PCB parts?

16: Cold solder joints on the PCB. (shoddy past work?)

17: Cracked traces on PCB (printed circuit board)

18: Acid damage to parts or copper PCB traces (guess who did that… ?)

19: Water damage (Someone Fording streams? knee high?, or running with broken windshield have you.?

20: Invasion of bugs, nests and POOP, dung, bug snot, spider guts.webs,etc… seen it all. Even had a spider plug up the on PCB BARO, and BARO was ok but failed.

21: Collision damage, vibration damage. Inertial damage.

22: Either of the internal power supplies, inside bad , there are two 5vdc power supplies, one can be checked at the TPS power pin. Dead, noisy, or loss of regulation.

23: Some IDIOT ,drilled a hole in to the PCB to re-route , traces missing. (there are better ways)He did this , and cut a hidden center layer trace in the PCB. wow !

Any of the 100s odd parts on the PCB bad. Not one part is extra or useless.

Questions: http://fixkick.com/bbs2/Suzuki-bbs/forumdisplay.php?fid=2

Comments:

This page is complex and so is the ECU , as I have only lightly touched the surface.

The ECU can fail in 1000’s of ways.

Parting shots: Bogus CAPs’

The Capacitor Plague is documented here.

And here At IEEE ! See artical there, called BOGUS

See this SAE Jargon here.

more jargon ?

PN or P/N is part number

CEL , check engine Lamp.

SES, service engine soon.

VSV, vacuum solenoid valve.

SMD , surface mount devices.

No technician or a shop is GOD. (nota all ECU’s can be repaired, due to damage can be unlimited and parts no longer sold)

My page shows the easy repairs: (all outputs++)

Not all bad ECU can be repaired, repeat NOT ALL ! (only by cannibalization of 1 , and 2 ECUs parts to make 1 good ECU, in many cases , may work)

Or not at all (burned main board, water damage or even lightning)

I have repaired boards (and the full component level ) from lightning damage that had almost every chip on the board blown out. (many times, on high end equipment)

No shop will do that, on any old Suzuki POS $50 used ECU, it’s not going to happen. (we scrap these, boards, for rare parts)

The page shows only the 3 most common ECU used in the USA, there are hundreds of other types used world wide and vary to an extreme degree in design.

DTC CODES from HELL DTC CODE 53:? (information from 10 years of FSM and experience)

Bad Electric raw D.C. power to the ECU, not getting full 12vdc power at all times. (the ECU has many grounds, check them all carefully)

Example some one put a CALIF ECU in to your, Federal car? oops. Code 53.

Worse is we don’t know what that does, driving (Failsafe mode?) or if 53s override all other monitor DTC errors)

Any post 93 ECU, put into an 1993 car will fail. Do not mix ECU’s (or PCMs)

1: ECU internal Memory corruption, bad microprocessor or memory in or used by the same. (can not be repaired in most cases, RIP) Very rare, this.

2: Low or dead ECU +5vdc power voltage to SENSORS, due to a bad 5v regulator , and this chip is no longer made or sold in stores this chip (RIP)

3: MIXING, California ECU in a Federal car body or the reverse. ( WRONG ECU !) very common.

3a: Really the same, but the ECU senses the missing EGR thermo-probe (EGRT) and throws 53s. use 10,000 ohm resistor at the EGRT pins, to fool the ECU.(or at ECU direct)

Only the top ECU houses like Cardone can cure #1 or 2 failures and do so , in a professional way. (w/full testing !)

Some failures can only be cured with parts no longer sold new. this is called cannibalization, in the business. (we collect useless ECU and use them for scrap)

Some examples of useless ECU :

1: Burned to a crisp in some way. (sometimes a hole is burned through the main ECU and that is END OF LIFE)

2: Acid burns, the CAP’S leaked and etched all the traces off the main PCB, endings its life.

3: Some idiot drilled holes through the main PCB to fix it, yes, the main PCB is more than 2 layers, and drilling the board, is near idiotic. (we have x-ray views in our shop so…)

In these cases we can cannibalize parts. Stealing from Peter to pay Paul is fair game, here.

Advanced and testing: ( This may be done on FULL ATE test gear) “You do get,what you paid for” I believe Cardone is one of the best, state side )

So, my 8 tests pass? and trip around the block test (geek level testing) all pass? , now you find the ECU dies with a low battery 11v or when ICE on the hood?

Welcome to full testing:

The pro. test engineer, knows that testing the D.C. tests first saves time buy finding hard failures like this first. (test time reduction)

The Test PLAN: (unlike the above crude methods) {at the least}

- Damage inspection, cracks of any kind, smoke signs, burned parts, burned up PCB traces (a skilled technician sees this instantly) {yes, skill is not fee}

- Some nincompoop put the wrong ECU PCB in the wrong case, amazing what some people do. Or mixed up country stickers (smog rules)

- At least 3 ambient temperatures ,the physical outside of the ECU is tested, between -40C to +100C (repeated during all D.C. tests and A.C. test)

- The ECU is also tested at a low power level, say 10v and at and extreme voltage say, 18v {estimates} (the internal ECU 5vdc regulator may fail here)

- The ECU changes injector pulse wides with battery voltage changes (calcs) to compensate for changed injector performance. This is a test in and of itself.

- The all inputs and outputs are checked leakage. ViH and ViL parametric measurements.

- The all digital inputs are tested for proper logic action and not stuck , internally.

- All analog inputs to the ECU are tested, eg: ECT, IAT, MAP, MAF.

- All outputs are tested for proper low signal and high signals. VoH , VoL parametric measurements.