| Sensor name |

Alt. name |

Function

Sensor or device. Items in RED are critical in starting the engine. |

Location (typical) 89-95. |

| IAT |

ACT |

Air temp, or Intake Air

Temperature sensor. IAT |

In the

intake tube or the intake

manifold plenum, not critical , it fine tunes! |

| ECT |

WTC |

Engine Coolant

Temperature senso ECT |

Screws

to water jacket on block or water outlet of thermostat housing. |

| MAP |

--- |

Manifold Absolute Pressure. Critical after Starting. MAP |

Connected

to intake manifold plenum. Vacuum sensor, electronic. |

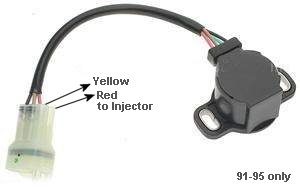

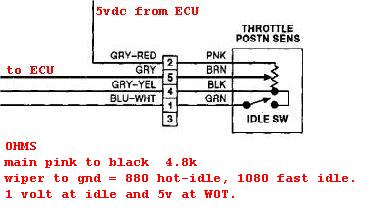

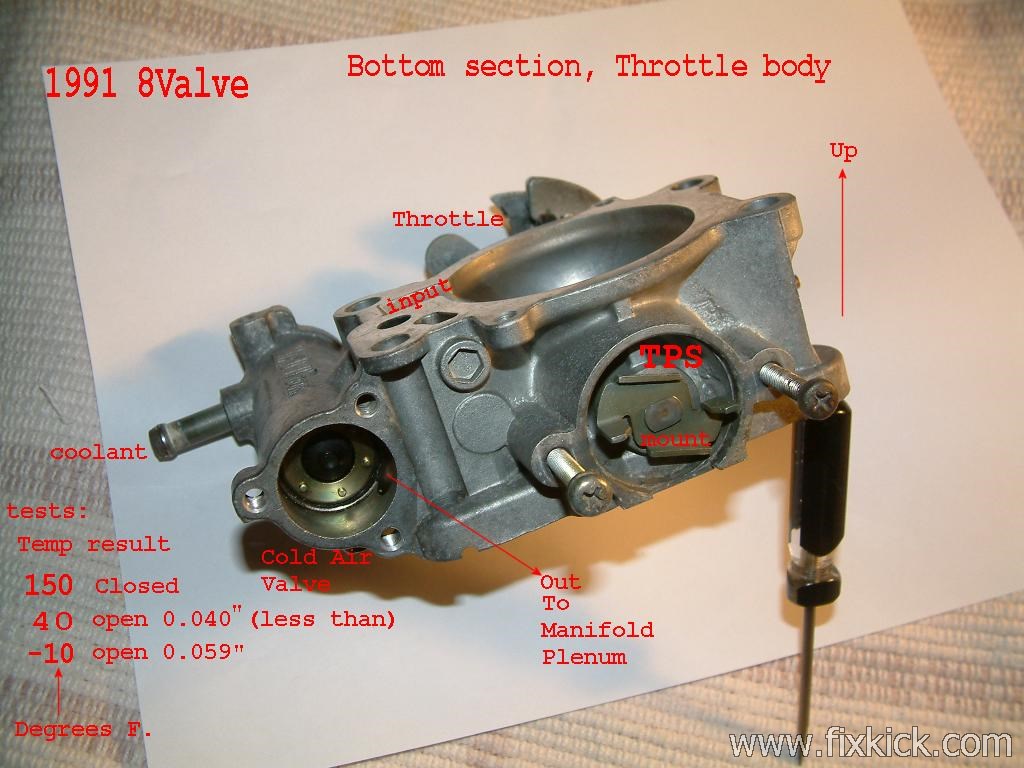

| TPS |

--- |

Throttle (valve)

Position Sensor TPS

with switch |

On the

end of the Throttle Body butterfly shaft. A Variable

resistor. |

| O2S |

EGO |

Exhaust oxygen sensor O2S ( HGEO = heated ) |

Located

in exhaust manifold (on old cars), new cars have 2

or more |

| VSS |

--- |

Vehicle Speed sensor. VSS |

Just

a rotation counter on the speedo cable. Cars speed is measured. |

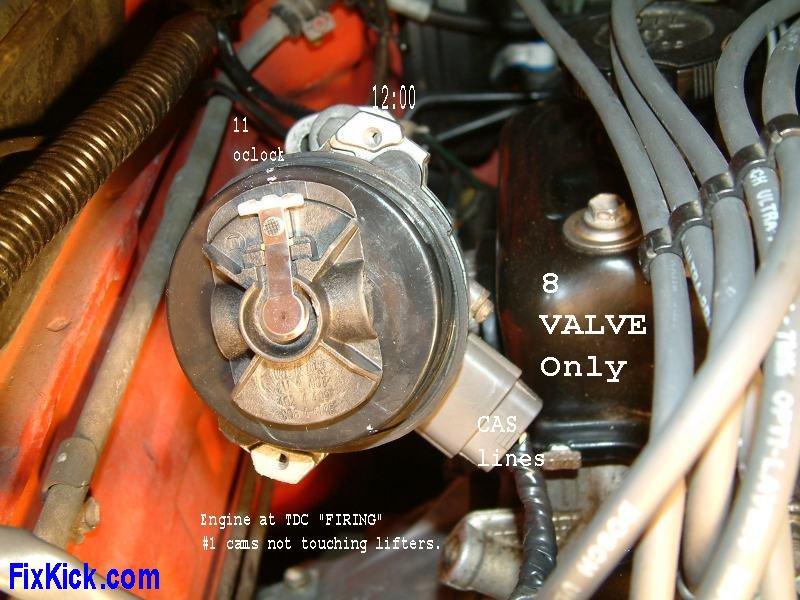

| CMP |

CAS |

CAM angle

sensor. CMP |

Located

in the old Distributor or on Cam shaft end , on newer cars. |

| CKP |

CPS |

Crank position

sensor CKP

(96 an newer) |

Located on

front of oil pan and reluctor wheel behing crank belt cog wheel. |

| EGR |

--- |

Exhaust Gas

Recirculation devices EGR |

Located

on Intake manifold and is not a sensor (but is,on somecars ) |

| MIL |

CEL |

Maintenance Indicated Lamp ,Check Engine Light | On

dash Lamp shared with SES.

Service engine soon. |

| PCM |

ECM |

Power train control

module PCM EFI

controller (suz) |

89-95

is behind left front speaker. aka:ECU,ECA,ECC, BRAIN or Puter |

| MAF |

AFS |

MASS Air Flow, Sensor MAF |

Located

on Air tube

between Throttle body and the Air cleaner. 95 and newer vehicles and

all 16valve engines. NEVER touch the HOT WIRE! |

| ISC |

IACE |

Idle speed Controller (a output

actuator

device) ISC |

ECU

Idle control

valve. Electric modulated Idle control device. |

| IAC |

IACT |

Idle Air Control IAC usually a thermo device |

Located on base of Throttle body

"TB" both MPI and TBI |

| Misc. |

--- |

Injectors, Ignition

coil, Fuel

pump, outputs |

Starter monitor, Battery

voltage monitor. |

| MPI |

TBI

|

Multi Point Injection and

Throttle body Injection. |

16v is MPI and 8v engines

are TBI . Vastly different EFI designs. |

| EVAP |

--- |

Evapoative Emissions |

Large black charcoal

canister and vacuum control purge valves. |

| TCC |

--- |

Torque Converter Clutch

(solenoid) TCC |

varies by year, some PCM's

(newer) have no relay ,ECU has direct drive. |

| TCM |

--- |

Transmission Control

module, 4speed only |

located high in dash above right

knee behind ignition key level. |

My Distributor, click to zoom.

My Distributor, click to zoom. A code Reader for 96 and newer

cars. Other older cars have other methods and devices for pulling

codes.

A code Reader for 96 and newer

cars. Other older cars have other methods and devices for pulling

codes.THE DUMMY SPARK PLUG: (get one)  This is the

best kind (IMHO) but, there are many more good types.

This is the

best kind (IMHO) but, there are many more good types.To test for spark , you should have a dummy spark plug connected (see above photo). Never short out any spark plug top terminal to ground directly or leave it open circuited. You MAY damage the ignitor device.[ a huge transistor ] or in newer cars the ECU will be blown out. ( integrated Ignitor). < best reason to not do it! ( the ignitor, is part of a High Energy Ignition, that which generates up to 50,000 volts, to spark the plugs ) The above is Sold in all Automobile parts stores. It is dirt cheap. Some guys just weld a clip to a new spark plug. RESPECT: ( this is high voltage and can be dangerous , unlike a lawn mower engine with 5 times less power) 50,000 volts, don't touch it while cranking or running the engine. It will be very painful! Even dangerous if it passes through your heart ! |

TPS

, located on the end of the throttle valve TB,

butterfly shaft ! This one is for the 8Valve engine.

TPS

, located on the end of the throttle valve TB,

butterfly shaft ! This one is for the 8Valve engine. 8V config.

8V config.  Click

to zoom , a broken TPS insides.

Click

to zoom , a broken TPS insides. MAP sensor sits on my firewall and a

vacuum

nipple connects to the intake plenum. (8 Valve engine.)

MAP sensor sits on my firewall and a

vacuum

nipple connects to the intake plenum. (8 Valve engine.) The

ECT Sensor.

The

ECT Sensor.  The fuel injector ,

inside the Throttle Body (TB)

The fuel injector ,

inside the Throttle Body (TB) AKA: ISC in some manuals. Click here to see my testing

page on this device..

AKA: ISC in some manuals. Click here to see my testing

page on this device..

A

New

MAF

A

New

MAF < << Click here to find out, how to

trouble-shoot,

test, evaluate and buy a new OxyGen Sensor.

< << Click here to find out, how to

trouble-shoot,

test, evaluate and buy a new OxyGen Sensor.