Suzuki TBI or MPI Fueling systems. 1989-1998. G16a and G16b respectively .

You are here, because the engine runs badly or not at all, and fuel pressure tests all pass. (The basic pump tests pass. seen here.)

No starts, flooding, stalling or bogging, can all be caused by injector problems. "fuel leaking from exhaust ports? or gasoline found in the crankcase oil?"

INDEX to my Injector page (See my linear step by step test page, to starting)

- Safety first:

- Tools the you need to work the fuel system.

- Basic inspections. ( inspect at all wires and connectors on the Injectors , its harness and at ECU connectors and all ECU sensors.)

- The 6 ways

the ECU can fail to inject fuel.

- Basic rules, hints , ways and means.

- Next are some basic tests

- WHAT is a NOID test or injector lamp? (can be

dead,

weak or stuck on, causing leaks) (only a scope never lies)

- TBI- 8 valve all tests for the injector here. (a leaking single injector or its 2 o-rings cracked)

- Advanced

8v NOID test. (finds out which TBI driver is bad)

- blank.

- I got raw liquid gasoline in my engine oil

pan or the exhaust flanges are leaking raw liquid and gas to the

pavement.

- MPI

leak tests. ( a.k.a. the Injector dribble test.)

- Full MPI balance test. not running.

- The MPI Running balance tests. are they equal flowing?

- Full MPI injector tests.

- Parts sources

- HOW to get fuel gauge test port

connected? all the ways.

This test tank holds a special cleaner and you start car running from said tank.

The injectors must fire on demand (by ECU) , not leak , not be clogged, fully or partially . Next up, I will review both EFI fuel systems fast.

Battery is charged and fuel is fresh , no bad fuel. Don t forget tools.

Learn how to use a NOID lamp first. (4 ways) (it's more easy, than doing fuel pressure tests first) If the NOID lamp test passes. Jump on fuel pressure.

Begin:

TBI first: (or Jump to MPI) This first section is for fast testing, the remainder of this document cover both engines in great details.

The injector is just an electromagnetic fuel solenoid valve. (12 volts is open, 0v is closed, a spring closes it with no power applied)

The TBI system has but one injector in the throttle body. (TB) Throttle Body Injection it is.

Anyone can take off the throttle body air horn and watch it inject while cranking, or running.

If the injector is dead, or leaks at just key on, or leaks after key off, the injector has a problem.

Lets do that first. if the injector leaks , at the tip, keyon , not started the injector is leaking, unplug the injector cable and if it still leaks at the tip, the injector is bad (or needs service cleaning) but of it leaks higher up?, then the o-rings are bad, there are 2 " o-rings".

Okay there are no leaks.

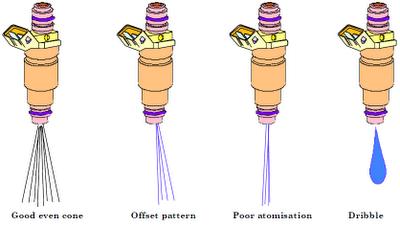

The injector is next checked for a nice spray pattern, while cranking, or if running . Click photo below to see a video of a Chevy TBI running.

If the pattern is bad, the injector needs service.

Note the conical pattern, see the this photo for other patterns.

If the injector is dead, then that is caused by many things, all easy to discover, with simple tests. ( Fuel pressure must be, at least 30PSI, or clogged injector , or dead injector (coil open or jammed) or ECU inputs wrong and last a bad ECU)

The TBI injector above must click (heard) each time the ECU fires it., if not?, then the injector is jammed, or there is no injection pulses or the ECU is blocking injections for up to 5 reasons ,see #2-6 here)

The Injector only needs 2 things to squirt correctly, minimum fuel pressure and the 2.5 mS pulses (about).

If fuel pressure is too high, say near 55-60 PSI, the pump regulator is bad, stuck closed, this will cause flooding or very rich running conditions.

The Injector coil (inside ) 2 pins must read near 1 ohm, (never 10 , never infinity ohms) Using any resistance lowest range scale of any multimeter DMM. etc.

The Injector needs to pass the NOID light test., using any NOID test lamp. (pro tools or DIY lamp, or scope) (this test proves the ECU is firing the injector and that the ECU is not injecting full time, even just key on)

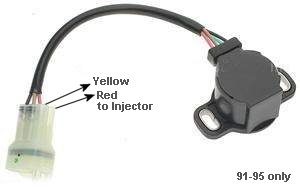

The TBI ECU has 2 driver wires that directly drive the above TBI single INJECTOR.

If either TBI driver wire fails to pulse , the injector will not flow correctly!

If the NOID is dead, we next must check 3 other input failures to the ECU that cause , injector CUT. (cut fuel) (I'll not dwell (no pun) on the lack of power to ECU, or its ground. or blown ECU fuse... or a dead main relay...)

- The Tachometer line is dead, this is the igniter line to

the COIL minus pin, if this is dead, the ECU cuts fuel forever.

The ignition suppressor can

be missing too. or Tachometer shorted, or Cruise module shorted.

(killing the brown wire from the suppressor dead.

If the Pin A1 brown wire

is dead,

so will be all injections dead. (The tachometer pin must not be

Dead)

A scope is the only sure way to test this signal seen on

this brown wire.

- The TPS sensor, TP pin, must not be near 4vdc, but near 1v

cranking, if it is near 4v the ECU enters cut

fuel mode to clear

flooding while cranking, (it's a feature of all ECUs' made) The

ECU does NOT pulse the injector in this MODE !

- The CMP cam sensor dead, kills spark and fueling, to

prevent fires. The CMP sensor almost never

fails, but the

connector on the side of the distributor has broken from time to time.

( look at the connector and pins for damage of any kind)

The ECU will not warn you of #2 failing due to its thinking(sic) that you are using super secret unflood mode.

Unlike some TBI Suzuki Swifts and Geo Metro's, this engine injector has no series, Metro injector resistor blocks to fail (a good thing!)

end TBI.

MPI: Fast tests...

The same rules apply here (basics) as the TBI system. (fuel pressure 30 PSI minimum) but they can not be watched with eyeballs.

If all 4 injectors (or 6 on V6) Are dead, and the fuel pressure is at spec, that means the ECU is cutting fuel on purpose. See ways 2 to 6 here)

What's not so nice about the MPI system , multi point injection (4 injectors) is they are hidden from view at all times, and 3 more injectors to fail.

The only clues, about them are gas dripping from exhaust port flanges, or wet or bone dry spark plug tips (and flooding)

The best clue for MPI is the leak down balance test.

The same rules apply to MPI as TBI , good fuel pressure, at Spec, (at factory specifications). The FPR must work correctly and also raise fuel pressure with throttle raised (vacuum drops, fuel pressure rises.)

The NOID lamp tests, all pass for all 4 injectors.

The injector coils read near 10 ohms, 10 ohms not 1 ohm like TBI has.

Same tests for the ECU, to see if there are spark errors or CMP errors, (DTC errors) using the DLC jumper or in 1996+ you need a scan tool.

The TPS voltage is near 1v pin 3(good), and Tachometer signals are not dead. (same 3 rules above) No DTC errors, 41/42 or P03xx DTC errors scanned.

What is more complex here, is doing a leak down test to be sure they do not leak, key on, no start. (covered in the pump test page, called leakdown or residual testing.)

The balance test, will find a weak injector, or dead one. easy. (and one stuck on too)

Keep in mine you can hear all injector click running, with a stethoscope. If they don't click the ECU is bad, wires bad to it, or injector is jammed up, or its coil open/shorted. (the NOID test finds stuck on, or dead injector drive)

There are 3 more injectors to fail, and 3 more ECU injector drivers to burn up in the ECU.

The 12vdc power feed to all injector can be dead.

end fast MPI sections.

Next up?, is the LONG play sections. (full details)

DE-PRESSURIZE FIRST AND READ ALL SAFETY WARNINGS < FIRST ! (use goggles, do not get fuel in your eyes!)

Do not breach (open) the system until you do, what the above link tells you to do. Please, don't get fuel in your eyes.

If fuel pressure is wrong, fix that first, see how here > Do not let a bad Fuel Pump regulator fool you!

The ECU cuts all fueling for these reasons:

- Lost of 12vdc power to the

ECU (IG- coil or "FI" fuses blown) or the ground to the ECU is

cut.

- CMP dead,

- The ignition coil primary igniter side

is dead (or coil it drives is dead at primary side of coil

) or the brown wire to the Tachometer is dead for any reasons. "anti fire protection feature"

- The TPS TP pin (aka,

throttle angle today) is stuck at near 4vdc. (bad) this can be a

cut ground wire to the TPS. This causes permanent wide open

throttle. About 1vdc is normal here.

- Bad wiring, all the above, or bad connections, or shorts to body or other wires. The 8v schematic is a great example of these wires.

- Bad ECU.

In all cases fuel pressure must be in spec. first. (if not, stop and correct that first)

TBI single Injector tests:

All G16A engines have the pump active for 3 seconds at key on (repeats) , but the 1989/90 only pumps fuel cranking (above 10F ambient)

The injector all here, have 10 micron screens, they must not be clogged. (the MPI screens can only be cleaned via back flushing or ultrasonic cleaning.)

- Put your Eyes on the actual injector, see it spray? (click watch it above) (remove the Throttle body air

horn and watch it.

- If the injector dead, check the coil for 1 ohm resistance

(0.8 to 1.2 ohms

is

spec) infinity is bad. A good

DMM meter on the lowest Rx2 range, will show up to 2 ohms due to

inaccuracies of cheap meters, it's a good injector coil.

- To check the Injector Coil for injection driver

signals, I then use my NOID

lamp.

(unplug injector connector and insert the NOID lamp in the place

of the injector) (see all 4 way to make up a NOID lamp)

- NOID lamp. must be out keyon, then flash cranking or seem to just be a yellow dim glow, as the photo 1 shows. This test is by no means 100% definitive. (for $1 lamp) A scope works 100% ,every time.

- The NOID lamp.works, (we

already checked fuel pressure is ok) so the

Injector is bad. if the coil is open (infinity or even 5 ohms its bad,

new injector time) Or the injector is clogged, clean it now.

- The NOID lamp. fails., so I

check the 6 item list again before replacing ECU.

- If the scope shows flat line on either RED or Yellow

wires, the ECU is bad. (or broken or shorted wires to here)

- If the injector is weak, and the fuel pressure good and the Red line pulse is over 2.5mS cranking, the injector is CLOGGED.

- If the injector floods and line pressure is at near 30 and

not near 50 PSI, then the ECU might be in BACKUP mode; Or the ECT reads

-40F all day long. (not in Alaska ?) If in failsafe mode, and ECT

reads wrong, it will flood.

- Fuel pressure at 50-60PSI (or over

spec.) is pump no in shunt mode (dead

headed pump; is real name) or the PFR return line pinched FPR to

tank line or the FPR is

stuck closed (its just a bad FPR.

- Same

tests, but the injectors can not be seen with your eyeballs. (sparks

tips wet or dry?, helps) . Are one of the exhaust ports leaking raw

fuel at the exhaust header flange? (if say #2 port leaks fuel then the

injector is stuck open#2)

- The MPI coil ohm test now is now about

10 ohms

using Rx20 range on the DMM and

all 4 read the SAME,

if not ? that injector is bad. They should all 4 read the

same ohms, , not one at 0, 20 or up to infinity ohms.

- Do the NOID lamp test (4

ways to do it, including a real scope) If all injectors show a

dead noid, that means the ECU is cutting fuel in one of

5 ways, (2-6) or you lost 12vdc Power to the injector power

bus , it's a daisy chain feed.

- If NOID fails , on just 1 line it's a bad ECU or the wire

between them is bad.

- If all test pass here, the only solution is the much harder balance test, a pressure gauge is mandatory. A $20 tool at HARBOR FRIGHT (pun)

- The fuel filter is new, the tool is attached to the filter

test port.(or fuel rail , is best for

MPI)

Any time the engine runs poorly, I check this. (and FPR regulation)

The injection rates, fail for the same reason, a bad Fuel Pump regulator , it must work and regulate right; test it !

All injectors must click and can be heard running easy, but is near impossible to hear this,on any cranking engine ! (I have a sonic hand tool, that can do this)

Or use 9vdc transistor radio battery across the MPI injector pins (never TBI) (smoke detector bat.). Listen for the licks as you attach battery wires. No clicks? is a jammed/bad injector.

The best tool I have and use is this tool that is SONIC ! (can reach very hard to reach V6 injectors easy)

On a running engine MPI injector clicking sounds must be equal. Any stethoscope you can hear this sound,

You can use a $5 Harbor Freight tool to hear them live , idling.

The below text goes into great details all tests, leakdown tests, flow tests, balance, tests. etc...

If and injector is dead, the NOID flashes and coil is good, and the pressure is good. The injector is bad.(or just clogged, it does have tiny bucket cage screens inside, that usually take backflushing to get clean in a PRO Injector Shop.)

One other way to prove any injector is dead is by doing the injector balance test.

Leaking injectors must be addressed first. (can cause a fire)

DETAILS, lots of DETAILS:

See a DUANE Video doing it:

HERE IS HOW AN INJECTOR WORKS.

The 8v , TBI car has a single injector and can be observed , by looking down the Throttle body bore. (air horn)

The MPI Quad Injectors, take more careful testing.

MPI

MPI  TBI Throttle body Injection.

TBI Throttle body Injection.In General:

Before suspecting Injector trouble, make sure fuel pressure is running at factory specification.( about 30 psi)

Guessing or doing squirt and dribble tests for the pump operation, are useless. Injector require a minimum pressure just to fire.

Some injectors just leak if minimum pressures, are not maintained, these injectors use the pressure to even close properly!

Can you hear the fuel pump buzz for 3 seconds at each key on? If not check out pump and its power source.

or see my Fast pump test page.

Rules, hints and facts:

- Low fuel pressure

(below 30psi) will defeat

any injector in the EFI system. Crank the engine to see if you

get pressure, many cars do not make full fuel pressure until cranked or

for sure running.

- The MPI ECU the injectors are all HOT keyon and the ECU grounds them to fire them (about 3mS pulses; never full on)

- The TBI

ECU has a ECU

driver for both sides of the injector , and is never HOT full time

or at keyon.

Both injector pins are PULSED on the TBI !

- Do not hot wire any TBI injector to test it, or burn up its internal coil , the MPI can be hot wired, under very careful conditions.

- Make sure car does

start with test fuel, before condemning the

injector(s).

- Do not condemn an injector, if the Diagnostic jumper test, while cranking shows code 41 or 42 ! (ignition fail) [P0335 or P0340 in 1996 and newer cars, USA]

- Do not blame an injector if cylinder compression is BAD. OR THE CAM BELT OR CHAIN HAS SLIPPED TIME.

- If the ECU will not Glow the CEL lamp at key on or flash code 12 or others, then the lamp is bad or, ECU is dead. {fuses blown sure}

- spare

- MPI injector leaks (and TBI) can be discovered, by watching fuel pressure drop as you key off the ignition, this is a leak down test.

- The TBI only needs EYES on the injector to see what it is doing. (pull the air horn, look for leaking key on 3 times, then for injections cranking.

- Be real sure engine is not flooded, look at the spark plug tips to discover this fact. Black and fuel soaked wet are flooding.

- Bad gas makes injector clog, or fuel just won't burn, bad gas is the top cause of injector failure. Put only fresh clean fuel in the tank.

- Bad injection can be caused by many a thing, . Send them out for cleaning, if you suspect clogging. Clean them for $22 each.

- Injectors are fuel cooled (coils need it, do not operate them dry. They are also fuel lubricated. (same as the fuel pump)

- New Injectors are too

expensive, get them rebuilt or exchange them cheap. See my buy parts page.

Tests: (basics on injection)

MPI means multi point injection , or 4 injectors. TBI is single. Throttle Body Injection.

The TBI is more simple and MPI tests include 3 more injectors and can not be seen injecting like the easy TBI injector

At this point, the system has good fuel pressure, good spark, test fuel runs car and it motor stops running, when test fuel is expended.

A technician at this point does not know if the problem is , ECU, injector or fuel pressure bad, and what fails is random!

On the TBI : (using the logic of simple tests to harder)

I unplug the Injector connector and check the injector coil first. 1 ohm , good ! On a MPI the same and get 10 ohms (good) times 4.

Never hot wire any TBI injector with 12vdc, or you will burn up the coil inside.

(use an injector tester or pulser , on the 16-valves , many folks use a 9v transistor battery to test the injector )

On the TBI (unique it is) I pull the air horn (see hidden screws under horn black plastic cover?)

The TBI motor runs great with no top air horn, (unlike any MPI)

At this point, many tech.'s with and TBI just look at the injector with their EYES ! " I do this first" on no starts.

The TBI injector can be viewed for SQUIRTING while cranking , just by looking down the Air horn of the Throttle body. (on MPI this is impossible)

The fuel squirts happen at the cadence of the CMP sensor. during cranking and running.

If it don't inject, you have , bad fuel pressure, bad ECU, inputs to ECU bad (TBI ECU, pin A1 dead , tachometer dead, and or TPS pin B stuck at 4v not 2v) or a bad injector.

If it don't inject, time to do the NOID lamp Test , NOW.

If the NOID test fails follow the NOID link above.

All injectors can be heard with a cheap mechanics stethoscope or an electronic sonic tester. (a rubber tube to ear?)

There is a tool that both can listen to the injector and flash and LED or pickup stray magnetic fields and flash and LED, this is just more NOID action proof and in no way proves

fuel flows.!

Compare each injector for equal sounds with a stethoscope (MPI) and see that they are not dead , not clicking.

With an o-scope one can see the signals and see the valve coil kick back (EMF) and that all 4 injectors, look the same (MPI).

A stuck injector can be seen with a scope.! (back EMF profile checks)

Testing injectors using advance tools is a complex topic but if must know , here is a Great page on topic "INSIDE THE WAVE ?".

For sure a scope is the best tool for working injectors or any PWM signals.

You have already check the injector coil resistances, and they pass muster.

If the NOID passes. then check fuel pressure and for injectors leaks and leak down failures.

The TBI can be checked for leaks (looking with eyes, after pressurizing the fuel lines (key on 3 times) and then checking for dribbling at the 2 o-rings , it must not leak.

MPI drop tests (leaks)? All fuel pressure checks (x8 test) are here.

If the pressure drops too fast, then the pumps check valve is bad, or the injectors leak. If the fuel pressure drops below 25Psi from 34, in 1 min. there is a problem.

If the drop test fails you could plug the fuel line to the RAIL and repeat the test to see if the leak is in the TANK or in the RAIL. (gage at filter)

If the leak is in the RAIL?, then block the FPR regulator return line, still fails?, then one of the injectors IS leaking.

The Fuel pressure tests can all be done at the fuel filter test port (bung) on the fuel banjo bolt, see 10mm screw? that is it.

IF fuel pressure is 60psi the filter is bad, it must be near 30'ish.

A clogged filter not only kills good fuel pumps but cause this test to read bad. The test port in on the input side of the filter.!

This ends my fast injector test section.

Safety first:

| Work Out doors and conduct

all tests away from buildings , people and valuables. (park away

from valuables and people and pets) Have a Fire-Extinguisher at hand rated for fuel. Class B rated and Foam is best. NEVER USE WATER. Park on concrete /asphalt , not on dry grass area. No smoking or flames of any kind near by, including gas fired water heaters !!! Or Space heaters.! No bug zappers, either. They are the Worst of the Worst. Wear long sleeve shirt and no plastic clothing of any kind. COTTON is best. Sock Hat and goggles too. Lock up kids and pets. Having a friend to hold the Fire Extinguisher is very handy. ( 2 extinguisher are best, if one turns out to be defective, then you are in trouble , not next to car but back a ways, so you have a clear path to it, under any event.) Always have a helper and always tell him/her what to do, if a flame happens. A large wool /cotton/ blanket or canvas can be really handy, if a flame breaks out. All people that work around gas have seen this happen, so if you are not up to this risk please stop now, and get the car serviced by a ASE professional. |

Proceed

at your own risk.

Proceed

at your own risk. You have 2 choices, you can take the risk or pay someone else? to take it.

Parts: Have a complete set of injector seals , ready: Sidekick 1.6L 92-96-- Suzuki P/N: 15716-58BT0

SEAL SOURCES AND P/N?

See my seals sources page here.

See my injector P/N and sources here.

The TBI Throttle body injection system , Single point injector ,what ever you call it , It is a single INJECTOR , hidden under the below plastic lid.

NO SMOKING and wearing goggles and a sock hat.:

BEGIN TBI G16A (SPI/TBI) 8 valve INJECTION TESTS: (spark is good, fuel pressure is 34psi , minimum!)

I will cover all ways this single injector can fail in this segment. (all fuses good, CEL on keyon, and runs on test fuel)

You may arrive here ,with a dead or weak or intermittent injector or one that leaks. (dribbles) ( most folks come here, when test fuel runs the engine but not the injector)

The Throttle Body Injector is easy to test. ( there is only one injector ,and is observable operating) Your engine may run on test fuel , until it's consumed.

You need hand tools for the horn pipe pull (air horn exposed below) a DMM, and a fuel pressure gage last (please de-pressurized first)

The top of the main air tube (TB to Air cleaner) has a plastic cover hiding the AIR HORN STUDS, remove this piece. , FIRST to see screw tops.

The TBI runs perfectly with no air tube. unlike any MPI G16B engine.

Remove the main induction , pipe from the TB air horn studs and any other mounts to the left holding said large pipe. (left is drivers perspective)

Despite rumors, using a hose to your year, you can hear the injector fire, cranking, I can't nor can friends... the starter is way too noisy. (special tools excepted)

The Throttle body "TB" is now fully exposed and the TB air horn is open and exposed like this photo shows.

The 89/90 looks similar but the ISC has no air tube or water tubes.

Do NOT REMOVE THE rounded gray plastic part with 2 tiny screws above the actual INJECTOR or said injector will fly in the air and shoot gas all over you.

Tests: Begin the Dribble tests: (all these tests below are a waste of time (just step 1 to 3) if fuel pressure is not at 30 PSI !)

Step 1: key on 3-5 times (builds pressure to 30'ish) no cranking, you might see a tiny squirt, this is the prime PULSE. if no squirt ,that is okay !

Hint: the prime pulse each keyon, is for purging air only.

GOOD, no leaking injector or cracked o-rings surrounding said injector.... proceed to step 2.

The good, the bad and the ugly The key on , no crank check , must not dribble. and cranking must not dribble either. (the balance test can find problems here)

Step 2: While doing #1 above Key off, and look for fuel dribbling off the end of the injector, Dribbling is a bad injector or a bad set of o-rings on same.

Yes, there are 2 rings that can leak and dribble ,so can the injector it self if bad.

The ECU injection drivers can fail too, and cause full time leakage or injection, just key on. (a bad ECU)

Pull the Injector connector, 91'+ years share the TPS connector, so pull it (it has locks do not force it) if this pull stops the leaks, the ECU is bad. (sorry !)

THE INJECTION TEST:

Step 3: Crank the engine, see the injector squirts over and over as you crank, look deep down and see a shower on to the butterfly plate below.

Nice Injections?, yes?, then ok ECU is working. jump to check 4 below.

No Injections ? , then ECU is bad, bad wiring to Injector or TPS. , no fuel pressure 30PSI minimum, or TPS is falsely signally W.0.T at pin B

or a dead Tachometer.

There only these reasons for no injections.

- No fuel pressure? (check that last, to avoid the fuel bath) 30 PSI is needed. (do last to avoid fuel exposer )

- TPS PIN B

signals wrongly?. over 3.5vdc cuts fuel, the

TP pin. (not signaling W.O.T, it must not signal that) (this is a live

connected test !)

- No Spark at the 4 spark plugs? (engine runs great on test fuel so , actual spark is good , so skip this step.)

- ECU senses Tachometer

pin A1 signal is dead ?, 89-95 IS

the dash tacho is dead?, in

the dash? , that is the reason for no injections. BINGO ! got DTC 41 cranking? or

code 42?

- GOOD NOID test? A Bad

injector. (clogged, or coil

open) {dribbling or bad seals on the injector are all bad, correct that

pronto} or very low fuel pressure.

- A Bad ECU, if the Tacho pin is good and the TPS pin is good and the NOID is dead. IT IS A Bad ECU. (inputs good outputs bad) BINGO.

- In all cases of ECU , EFI troubleshooting wires can fail or

connectors/connections can corrode and fail too.

- This fact above (connections) is A GIVEN BACKGROUND FACT for

ALL ELECTRICAL WORK. (check continuity and insulation)

Be sure to Crank for 3-5 seconds with the Diagnostic jumper planted in the DLC next to the battery. (see code 41s flash out?)

This jumper is harmless, leave it in place until the car runs perfectly (intermittent are common on old cars!)

See TBI advanced NOID testing here.

See how the driver pulses, really matter

STEP 4: On a Running TBI engine, look at the pattern, does it look as a nice cone spray or is it squirting side to side or some strange way. yes?, Injector is clogged.

NOID TESTS ARE GOOD !

Weak injections or a odd distorted spray pattern? A dead injector and NOID test passed ? and the 1 ohm test passes?

The filter test port 6mm (M6x1.00p) (banjo) shows 30 PSI cranking or running.? Good clean fuel? no water in fuel? No rust in fuel?

All pump and reg tests pass here.

THEN:

Depressure the system next:

5: Remove the Injector and clean the screens. (10 micron size) (blast them with CARB cleaner.) or send it out to witchhunter.com. $19 clean and test. ( and flow data report!)

Witchhunter sends it back with 2 hard to find, injector O-rings , too. Most 1 ohm (passed) good injectors come back working., very few, are not serviceable.

Keep in mind the ECU cuts fuel for only 2 reasons: (a dead NOID )

1: WOT ,wide open throttle cranking (magic un-flooding mode of ECU) TPS pin B above 3.5v it must be 0 to 2v max.

and

2: Loss of spark read back (dead tachometer , see that?, on the ECU Brown wire pin or a ( missing Ignition suppressor)

That was easy , no?

How to find Injector seals.

Your engine now runs. HIGH FIVES ! hooray. !

See the MPI NOID page now.

See TBI NOID testing.

Begin G16B MPI tests: 92-98 USA.

There are may ways to for MPI Injections to fail. Keep an open mind, a dead fuel pump? , weak pressure, fuel filter clogged, FPR bad.

Low fuel pressure, dead pump or weak pump.

Sure, if the fuel rail is dry, the pump is dead, or ECU is not closeing the pump relay?, for some reason.

All 3 ways for the injector to fail times 4.

You might be here, due to 1 injector not clicking or one injector, or while unplugged, causes no RPM drop, because pulling each injector plug one at a time and found one cylinder dead, (check compression and spark here carefully, now...)

or one exhaust port is dead cold.? Bad fuel, clogging up my injectors?

You are here because fuel pressure is perfect (over 30PSI, but not over 50) and all fuses in the car are good. There are 3 ECU /EFI fuses, IGcoil., FI and Dome.

You have perfect fuel pressure and the filter on the car is fresh and new.

There are 2 tests. one is called balance testing, and the first is leak down. (if leakdown fails, blance can not be checked at all)

The MPI injectors have a ganged 12vdc power bus, at the rail power pins (x4) to each injector and measures good at 12-15 vdc key on and cranking.

(only MPI has a hot power rail , never does any TBI motor ! )

On MPI cars the Injectors can go dead, leak, clog up and dribble . If they do , the ECU goes crazy, due to 02 sensor seeing false excess oxygen. (from misfiring)

Do the injector click tests.x4 (listen for the clicks on all 4 injectors) If one injector fails to click , check the coil ohms for about 10 ohms , not: zero, not infinity. (all 4 should read the same ohms)

If the ohms tests (resistance ) passes then do the NOID check.

The NOID lamp test, will be used to check Injector signals from the ECU. (the inputs wrong to ECU can in fact, stop injections, totally)

A DSO or Oscilloscope excels at injector testing, I will not elaborate here on that topic but , it can find sluggish injectors, and many other weaknesses.

The NOID is a useful tool. ( if it shows no pulses cranking , then the ECU is bad or the ECU thinks there is no spark or the TPS is signaling WOT , full time)

If the engine runs you can listen to them with a stethoscope or a rubber-hose, to your ear. (equal sounds a must) click,click,click....

You can measure exhaust header tubes with an IR thermo pyro test gun, to see if any cylinders are dead cold or weak (lower temp). ( all must be close to the same temperature, no cold ports.)

You can unplug injector connectors on a running engine, to see if RPM drops. if not?, the Injector is dead, or spark is dead.(or worse).

You may suspect your Injectors are clogged, or dripping(leaking) or weak or dead. Looking is impossible on MPI, but leak down/power balance tests work great.

(using a tiny camera probe cable sent past the throttle valve deeply, one can key on see them leak. (getting to each port , will be not easy)

If all 4 injectors are dead, the ECU is thinking you have no spark or the TPS is stuck at wide open throttle (TPS fail).

If one injector fails to click and the coil checks out at 10 ohms (about) , this can be jammed injector, or bad ECU injector driver (if other 3 work).

If the injector wires check out okay (inspected end to end and continuity test pass), then the ECU is bad.

Injector fails:

A dead injector

(clogged , burn open coil, jammed,or dribbling ) , will cause no RPM change when you unplug it.

If you are sure the injector is bad, many people Pro's and DIY, just send them to witch hunter.com and all is well.

New Injectors are very expensive and old ones can usually be repaired. for about 20 bucks, each. Most can be cleaned, recovered. (and balanced)

See my rebuild table for restored injectors.

You are very sure one or more injectors are not squirting properly. (or are dibbling and making morning starts , hard and black smoke )

Dribbling is what injectors do , when power is not applied, and this injector floods the engine . It will also cause IDLE misfire. (and hot engine restarts, very very hard)

Clogged injectors are easy to find, because this spark plug TIPS are dry, at all times.

The leaking injector tests are NEXT: (DIY, with almost no tools and no Gauges in shop)

The Injector leaks on the MPI engine tests and then the dead injector test

Aka: The dribble test.

(the best test for this uses a gauge and is called by Suzuki the Residual test, or a real leak down test.)

First off , this test can not be done to any cylinder with dead spark, or very low compression, because gross misfiring causes flooding.

- On

a dead cold engine, parked overnight, (plugs pulled now, are the spark

plug tips wet (yes?, then the injectors are leaking) 1 or more .

- On same cold engine (parked long time), key on 3 times,

don't start it or crank it , and see if the pistons tops go

soaking wet in fuel.? bingo, leaking injectors. (a bore scope camera

works great here, a $30 tool now)

- If the above passes. We can do a hot test next, Engine hot. (stop engine, remove all spark plugs, and keep looking in the spark plug holes for liquid fuel, showing up on top of the pistons (again, a bore camera works great here)

- Running the

engine and looking at spark tips and seeing fuel raw there, can be bad

spark or very low compression on the wet cylinder, so is not a true

definitive clue to leaking injectors

- Time to do a NOID test?

- Remove spark plugs on hot or cold engine, even a no start engine.

- Crank for 5 seconds.

- All 4 piston tops must be wet with fuel. All 4 show signs of flooding, If not , the dry hole is a dead injector. If all 4 are dry the ECU has halted injection on purpose, (fuse blown? IG-COIL or "FI") or the 6 ways.

- Time to do a NOID test.

The G16B MPI PRO methods, of Pressure Balance test: Don't forget to review Duane's tests, he covers all this and more.

The FSM covers this:

Each test is covered in the FREE 1996 FSM. Volume 2, chapter 6E3-C2 page 12 covers keyon and idle pressure (skips, wide open throttle tests) then page 24 shows the balance test. the rule of 1.5psi difference drop injector to injector variance, is spec.

Injector Power Balance test: (do not attempt this test if the fuel pump residual test fails, that is, the RAIL don't hold pressure steady, key off.)

You need an injector Pulse tester, a fuel pressure gauge and a rail test port adapter. (using a gage at the filter banjo at tank, is hard to see as you work a injectors by hand)

This is the best way, the factory wayor the ASE way.

- Unplug all Injectors. (electric conn.)

- Connect an INJ Pulse tester (some. use a std 9vdc smoke detector battery ) to the injector under test. See warnings on how to fire the injector manually.

- Connect Pressure gauge to the Rail adapter.

- Key on , no start, , repeat on and off keying, until pressure stabilizes. Note pressure is about 35psi , if it don't hold steady, one injector is leaking. Go to dribble test above.

- Key off, note pressure, is it holding, if it is ? proceed, if not ? then the Residual test is failing, for reasons, the check valve in the fuel pump could be rusted and bad or one injector is leaking. or FPR is stuck wide open.

- Activate

test pulser (or 9v battery to the injector coil- DIY

methods.....) The

injector should fire and the pressure should drop fast. If not the

injector has issues.

- Repeat all steps above for

each injector. Take note of the rate (seconds to hit 0) that each

injector leaks

down. If one injector is slow, then it is clogged or

internally jammed up.

- If any do not droop on application of pulser or 9v battery , then they are dead, and might still be cleanable. (always do the coil ohm test first, as open coils is a bad injector , they are DEAD for ever, buy a new or rebuild injector now.)

One trick is to block the return line of the FPR regulator and key on , key off. this will hold the pressure steady. (if it does the FPR is bad)

I pinch the return like at FPR, and pressure goes to 50PSI + keyon, I then turn key off, if the pressure drops now, the injector is leaking or the check valve in the pump is bad.

I have no easy way to test the pump check ball (valve) But if the 5 checks DIY above pass above. then the check valve is bad in the pump.

MPI: Power Balance test 2: (say you suspect a weak injector ?)

(running test and is tricky, you must defeat the ECU idle controls)

This test is like a spark plug shunt balance test. This test is for advanced mechanics, using idle Speed, over ride tricks. "the ECU will want to fight you"

- Hook up a tachometer and the fuel pressure gauge mentioned

above. Hot engine. It must be hot, or the

idlespeeds will vary as engine heats up, making this test impossible to

do.

- Unplug the IAC

electric idle AIR controller at its plug. ( this kills

automatic idle

controls ,a steady idle needed, and you don't want the ISC

fighting you now.)

- Start the engine and keep it going. (find a way to

get a steady idle , by shimming the throttle stop screw or?)

Attempt to get a steady idle no matter how much the engine shakes.

- Write down this idle speed, after getting the idle

steady at 800 to 1000 RPM. (shim the throttle someway)

- Unplug the first (any order) fuel injector , just one at a time , never more than 1.

- Note the RPM drop? If any?

(no

drop means the cylinder is

dead, keep an open mind, it can be many things , not just the

injector bad, wires and ECU driver can be bad.) See of all

cylinders drop RPM equally, if not, it is a weak injector (maybe)

- If it doesn't drop RPM the cylinder is dead "compression

bad" ,

the spark is bad

or the injector is dead. (a bad head gasket , fouled spark plug,

fuel wet

plug or antifreeze fouled, check all these things)

- Repeat for each injector and expect similar results from

each injector. I good engine and injectors all drop RPM with a

pulled injector harness connector., and the drop would be equal for

each.

If the dead cylinder is perfect in all ways , it might be the injector. SWAP THEM. and repeat the test. Swap a dead injector for any of the others. Check the coil ohms, for about 10 ohms, not ever infinity.

( Ohm test the injector coil then , NOID test it and then listen for the clicks again with a stethoscope. , If these test prove good , then send these injector out for cleaning or proceed to the next test.

Do not forget to swap INJECTORS, TO SEE IF PROBLEM FOLLOWS THE INJECTOR !

Complaint?, "My oil pan oil is full of Liquid gasoline, or the exhaust flange is dripping raw fuel "

- You

did not crank a dead engine for 1 full hour, right? only a

minute

max cranking

, or it may flood, if spark is bad, and ECU thinks spark is good

(it can) then it will flood. (the ECU only sees primary

side of spark) (a bad spark plug wire?)

- What it is wrong, is the Injector 1 or more injectors are

stuck on. (for many reasons)

- What we do, is the INJECTOR residual test (leak down test) or MPI here .

- The causes are,

injector bad and stuck on, ECU bad if only 1 injector

leaks, Injector wire shorted to ground. If the leak down

test fails and then still leaks with the injector unplugged, that is a

bad injector.

In rough terms,

it takes the retina 50 milliseconds at least to integrate information.

Then a minimum of 100 ms for the brain to integrate. And more like 300

to 500 ms to integrate "consciously" as an act of attentive awareness.

Read more: http://www.physicsforums.com

Read more: http://www.physicsforums.com

In rough terms,

it takes the retina 50 milliseconds at least to integrate information.

Then a minimum of 100 ms for the brain to integrate. And more like 300

to 500 ms to integrate "consciously" as an act of attentive awareness.

Read more: http://www.physicsforums.com

Read more: http://www.physicsforums.com

In rough terms,

it takes the retina 50 milliseconds at least to integrate information.

Then a minimum of 100 ms for the brain to integrate. And more like 300

to 500 ms to integrate "consciously" as an act of attentive awareness.

Read more: http://www.physicsforums.com

Read more: http://www.physicsforums.com

In rough terms,

it takes the retina 50 milliseconds at least to integrate information.

Then a minimum of 100 ms for the brain to integrate. And more like 300

to 500 ms to integrate "consciously" as an act of attentive awareness.

Read more: http://www.physicsforums.com

Read more: http://www.physicsforums.com

Killing spark: (note 2)

Pull the single HV center coil wire. (on 96+ pull all 4 HV wires at Dizzy cap, mark them first 1,2,3,4, don't lose firing order, on HV wire ends.)

Front is #1 cylinder on RWD cars.

Pull all COP, connectors. 1.8L and newer cars. (coil over spark plugs) coils. or COPS. 1.8L 2.0L and V6 here in USA use COPS.

Keep in mind the ECU see's spark "read-back" and if it "thinks" spark is gone it cuts all fuel. (all ECUs do this, by law)

I don't want it to do that, I want it to think it's cranking and starting ,and me seeing it mess up.

A FUN VIDEO:

I do not advocate cleaning injectors for Squats and Giggles ,but if they are dirty or unbalanced then by all means clean them.

See it here:

http://www.youtube.com/watch?v=DUPqrgZdIU8&feature=related

Having injectors out of balance can rob power from the engine. This is because one cylinder is weak and robs power from the others.

It is like have a team of horses and 1 in on drugs or lame.

Worse is a dead injector that lets oxygen leak past valves (gross misfire) and the O2 rails lean, then the ECU goes rich as a pig. WRONGLY!

This last statement is why MPI motors, can be a hair puller.

Good Luck to you.

CLEANING INJECTORS : (IN MY OPINION !) Some considerations....

A Great Service co. SEND THEM OUT:

Injectors cleaned in Washington state, at witchhunters.com about $20 bucks each.

I'd never run "SeeFlome"(sic) , it's just PALE oil. why mess up a good 02 oxygen sensor and CAT, with that STUFF?

The TECHRON has the BEEF ! See the Benzine and Xylene? , that's the POWERFUL solvent , missing in most cleaners. Sure, costs more, but is MORE.

Hell, just run Chevron fuel, and be happy.

I really do not like any additives to my fuel or oil. ( I never mix chemistries , not me , not unless crazy or desperate) Desperate can happen, far afield.! No shame !

I run with , "out of the bottle {jug}" engine oil and stock island pump fuel.

"Some do no harm"? sure, like "HEET" (tm). but others are not safe at all to mix, and all car manufactures warranty's show "void if used". Ever wonder why? "Damage"

The truth is , there are no limits on the contents of any Snake oil (can be anything in there...)

If using any oil additive , "is this bottle of snake oil (additive) safe to use, in my Mobile 1 synthetic oil, or or (FILL IN THE blank here), of the vast brands and grades of oil?)

Not even the Mobile 1 engineer can answer that, why do you think you can.?

The same idea applies to my fuel.

Additives in fuel? , I'd limit myself to , Ethanol, methanol, and Cheveron Techron.(benzines + A Very good product) (read the products MSDS sheet to see what it is, first, then decide.

I never add OIL to my gasoline, sorry, will not. (except my 2 stroke, weed wacker, LOL) Many additives are mostly just oil or Stoddard solvent, either useless or bad. (toss a coin?)

TBI:

Here is my TBI Hunter injector report. All flow rates are there , and is a SUZUKI lil' secret , 111 CC/minute

Rockauto.com has both injectors new, and rebuilt , do not confuse MPI with TBI injectors, when they list both on a TBI page ! ed.

They have and excuse, that is SUZUKI uses the same engine VIN code for both engines, one of the worst WTF ideas,ever?, (GM /GEO corrects this blunder....with VIN Code 6 & U and a RPO tag with Engine codes...)

The auto stores that don't check VIN ( engine code) sell you the wrong parts half the time !, or 2/3's if 1.8L (the 1.8L has its own VIN code, ! so no excuses for those blunders.)

You get the wrong parts because SUZUKI , dang-me, uses the same VIN for TWO ENGINES, and is really a royal pain in the ash can, that ! but 1/2 the parts stores correct this by asking, TBI/MPI? but some ask for KV or KC, (V = MPI)

The hardest thing in the world is buying injector seals kits that fit. (wow)

Please conduct any fuel tests, at your own risk.

No smoking please, read the safety first section above.

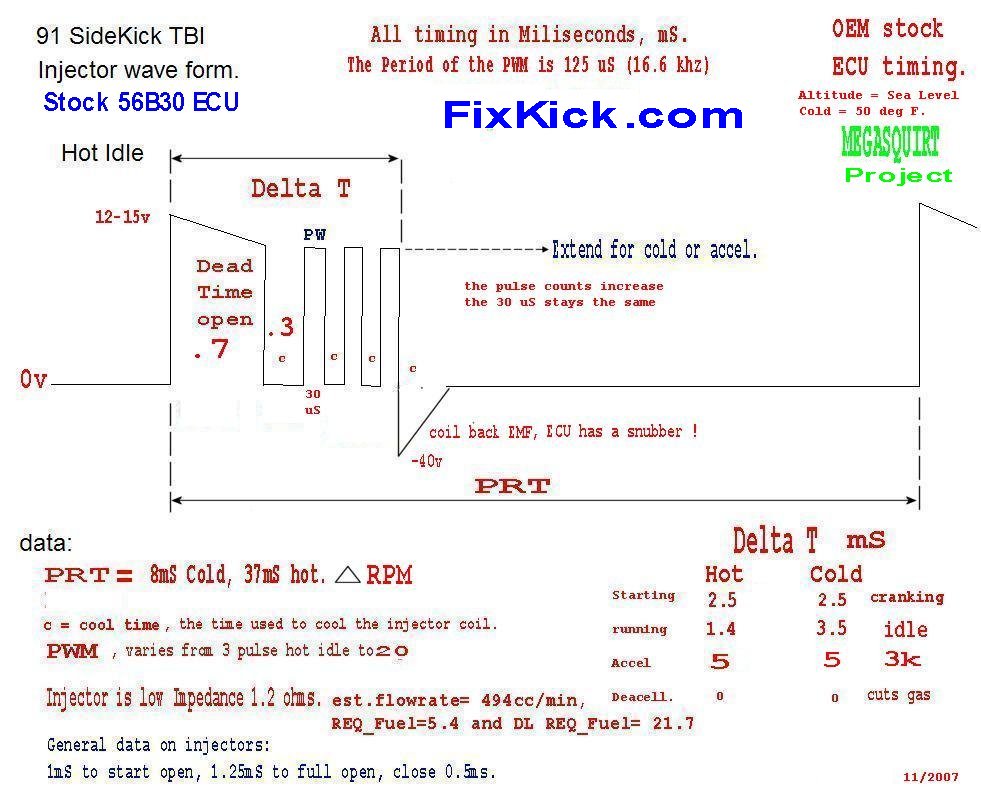

More facts,? Here is my 8 valve TBI injector drawing of my scope views, "integrated for clarity"

You can see the ECU modulating the injector (PW) to keep the coil inside cool.

The Delta "T" is the total injection time. (true) dead time is that time the injector takes to wake up, that is the delays from inertia and magnetic build time and the spring inside.

A scope works the best, but a duty cycle meter (mode on a Fluke 88 ) may read wrong, but on the Fluke they have a DUTY CYCLE average feature, that works good.

Keep in mind on the 8 valve, the low side driver can fail (short), and this will make the injector stay on too long, and is totally missed using any NOID lamp.

This reading below is Transverse connected, across the RED and Yellow injector leads.

To fully test the drivers you must scope 3 ways, Red to ground, yellow to ground and las transverse (pin to pin) , below.

There are only 3 ways to check this, NOID, SCOPE or DUTY-CYCLE METER.

At hot idle the duty meter might read. 4% (1.4/37) and rise to 15% at 3000 RPM (in neutral /park) up hill , far more. with 1000 pounds of luggage ? (I use a scope, any scope can do this)

Many Duty meters, only work on steady Pulse (same each hit) signals, and may get totally confused digitizing that 16khz noise ! Some expensive Fluke meters can do this.

There is a free (design) MPG gauge that connects here, and does read Delta T minus the dead time. You could use this gauge to diagnose fuel injection rates.

The Fluke meter averages this signals and shows the PW chopper rates as a tad lower PW. on a cheaper meter , it shows nothing or shows True delta T. (luck of the draw for sure)

The below is off a real scope, 100mhz. A 1991 TBI. the 30 uS chop is the injector cooling technique, used by the ECU , logic.

PRT = Pulse Repetition time. The PW might hit 22mS up hills. (not tried) "Pulse Width"

Injector

pulses are about 2.5 milliseconds long, minimum

Injector

pulses are about 2.5 milliseconds long, minimumOn the MPI engine, we check that the 12vdc power rail to the injectors is not bouncing, (scope) (running) (looking for corroded injector wires, pins and harness pins)

Then each injector has a single ECU grounding driver, (transistor discrete) that pulses to ground and looks just like the above, (modulated too)

The ECU fires the injector on the MPI by grounding it for 2-5 mS. cranked.

(I never do this (chicken), I built my own injector pulser box. (dual 555 timers or a PIC processor in a box (programmed )) But others rave about it... so.... here....

The MPI injector is 10 ohms, use any resistance meter to check them, all must read the same. Do not use this on any TBI injector.

We do this , with the fuel rail charged at 30 PSI (about) then key off and see the pressure hold, first then... touch bettery leads to the injector pins (unplugged for sure)

Then we connect this battery and see how many seconds the fuel rail pressure drops to zero, with battery attached. (called the injector balance testing)

If the times are all the same then all flows are assumed to be good. (in some rare cases, all 4 injectors were 1/2 clogged)

(the leak down test (injector all unplugged) must be passing first. obviously)

ALL 4 injectors must inject equally, or it is clogged. (equal time, to drop, is equal flow rates) but this battery will drain fast.

The injector can be heard to click now. (even with car key in pocket) If not clicking, the coil is open or injector jammed.

It can find dead injectors easy.

The best tool for this job is an injector pulser box $120 (tool), but the below is safe to use. (the battery will not last long, use it for 1 or 2 seconds, or so only per injector)

A 10 ohm coil can be burned up easy, of you don't watch out. This weak battery prevents damage to the coil. (internal battery resistance protects coil) { I'd not use a Lithium battery here}

Tools: Sure you need tools.:

At the least ,

- Fuel pressure gauge. Seen at all HarborFreight tools. and

at any autostore on earth.(cheap set has the 6mm Suzuki hose that fits

the fuel filter)

- Any DMM meter , even the $10 walfart meter

works, for sure. (sold just about everywhere, Sears,

autostores. Northern tools. etc)

- No need to mention hand tools, spanners, wrenches, screw drivers. etc.

- If G16B MPI engine, the fuel rail adapter by

Autometer, is crème de la crème (sold

at summitracing) and allows you to connect any USA NPT gauge. 60psi or

80 psi. (makes balance testing childs play)

- Eye protection, and a fire extinguisher.

- A hand operated, vacuum pump, with vacuum gauge built-in. seen at Harbor Freight, they have a nice brass one.. cheap. A must for FPR testing.

- The schematics here show which pins are which, on 4 different year ECU's. 1989-96'

- This is nice too , and for sure on V6

engines. (any V engine)

Buzz words?, Jargon, and this:

ECU/ECM/PCM is the EFI injection brain or the Fuel injection controller, prior to 1991 (USA) this controller does not generate or CONTROL spark in ANY way shape or form. (the 89/90 does monitor spark and does cut fuel if spark dies.

EFI means electronic fuel injection

The MPI G16B , Multi-Point Injection, or TBI G16A Throttle Body Injection Systems.

Injector. This injects fuel into the ports or throttle body, ports means, the InTAKE valve ports.

FP regulator or fuel pump reg. or regulator is that device, the keeps fuel pressure correct for all THROTTLE angles and all ALTITUDES. The TBI and MPI, work totally different.

CARB, means the old technology (style) Fuel system. (gone now, from about 1987 to present) Carburetor (US)

NOID, is a simple light bulb to check injector signals, it's not too good but finds dead signals or stuck on, easy.

PSI , pounds per square inch, GRINGO pressure. no one else on earth uses this. But I uses what the book says. The FSM book,

FSM , factory service manual.

OHMS, (ohms laws and ohms is a unit of resistance, we use meter any meter to measure resistance and is presented in OHMS , we can check continuity for 0 ohms or infinity for open. (we'd say "OHM it out dude"

MPI is 16valve head, TBI is the 8valve head. (The TBI is also called SPI for single point injection) MPI means multipoint injection (common rail)

PWM, the injector is pulsed, it's is never full on. PWM is the technique of Pulse Width Modulation. The PWM modulation also cools the injector as does fuel flowing through it.

1 mS, is one millisecond, or 1/1000th of a second, the cranking injector pulse width on my engine is 2.5 mS.

RPM , revolution per minute, is how fast the engine spins, and is displayed on the DASH on most 4WD Suzuki's

W.O.T means wide open throttle , Smokey and the Bandit, calls it PEDAL to THE METAL.

Duty meter, is a meter or scope that can measure, Duty cycle , the ratio of on to off. in Percentage.

The stock cars, ISC controller is set to 50% DUTY hot normal 800 RPM Idle, some expensive meters can do Injectors. ( I use a scope to measure PWM signals of any kind)

JARGON:

rev.18 . . 4-8-13 , 6-16-2014 and 4-1-2015, added tools and fast testing on top. exported NOID page.