In order of easy fixes to harder. duty cycle calibration can cure this problem or make it worse or can be impossible to do.

The ISC , idle speed controller (has 2 wire connector) opens to increase air supply RPM and closes to reduce air supply and RPM , the ECU does this, the ISC is just and electric SLAVE AIR VALVE.

The ECU is hard coded for 800 HOT RPM and 1000 in ECU fast IDLE mode. This page covers getting the 800 RPM back, HOT. If the fast idle pins are wrong, see here for correct voltages.

This page, below assume the engine runs perfectly, because if it does not , IDLE controls go out of control on poorly running engines. (for any reasons)

Engine Power loss or low engine RPM are usually weak engines, are covered here.

Power loss is low rpm , the page below, is for excessive RPM , that is the idle speeds are too high HOT. (hot means 180F or more holding steady, and not doing this Frigid failure thing!)

On a good running engine with high rpm the root causes (macro) are:

- Air leaks (vacuum hoses cracked), or stuck open air valves. ISC or IAC thermal valve failure or TV valve (throttle valve or its cables) stuck open or some unscrewed the idle bleed "DUTY" screw 8 turns.

- Or ISC dead. (ECU runs the ISC and the ECU can in fact decide the not control idle, at 800RPM, it can be in fast IDLE mode (1000RPM) or in failsafe mode, (see Engine power loss page above for failsafe causes)

- The ISC is dead because the ECU sees the TPS idle switch is open, (not calibrated of hacked by the unknowing)

- The scan tool shows idle Duty Cycle is out of whack or out of control. (or you attempt to set duty cycle and you can not attain 50%)

- The ISC can just get dirty and stick. (just clean it)

- The 8v engine all illegal (breaches)air leaks to the plenum

can and will cause high RPM, too high, The 16 value engine (tricky) can

go both ways, if a pure air leak? it goes lean, if it's a metered

air leak it races too fast.(can)

More Evidence? A fully Hot engine. (most of the below, show idle speeds too fast or hunts or surges)

- A "real" scan tool shows duty cycle and RPM out of control? (duty , no accessories on, is set to 50% DUTY hot, must be near 800 RPM hot) ( given ! NO DTC errors set or seen ! if yes, work those errors first.)

- Does the real scan tool show parameter #2 at

1000 rpm?, that is because fast idle is in force (demanded by inputs to

ECU) << OBD1 example. Means one IDLE up pin is set

ACTIVE. (fix this first)

- Idle regulation failure (speed varies) means an out of

control

idle speeds.

(under all accessory loads, Head lights and blower in same time, holds

800 RPM) if not?, it's OUT OF CONTROL.

- Not at spec. 750 to 850 RPM?, if higher or lower is "out

of

control" Hot. (A/C on or P/S overload is 1000 rpm hot

idle

normal.

called "Idle up"to the ECU. (89/90' have more ECU

idle up modes at and odd 920 RPM)

- ECT viewed with a SCAN

tool , must not read 140f , (a bad Thermostat!);

I can also use my Pyro heat gun to

see this FAILURE MODE or the

CLASSIC missing

rubber ring on

the STAT rim)

- RPM fails to hold 800 RPM when you select DRIVE

(on

the shifter) , that means it's (ISC) Out of control. (or the Drive wire

to ECU is cut or shorted)

- The scan tool shows O²closed

loop failure at idle?, this needs to be corrected first way before idle speeds matter, see power loss link above.

- Idle control is but one of many major EFI Servos. fueling rates, spark rates (advance etc) and last is idle, if the others are all off spec, idle is the least of your engines problems.

- See

Hoses cracked (vacuum hoses)? or fell off, or misrouted, or clogged up?

(inspections do work) (fuel leaking from the

FPR nipple? the FPR is BAD.)

- The correct duty cycle reading from the meter or scan tool

is 50%,

- The idle speed can hunt or surge ( not lean surge) the SUZUKI early ECU's have a software (firmware) bug, that will hunt the ISC when the ECU gets confused. (a truly bad act and is dangerous to allow) Pulling the ISC wire connector, will end this hunt.

- This

bug happens when anyan air leak causes a huge fast idle speed, and the

ECU sees that wrong(RPM sensors) and closes the ISC, then sees

that it can not attain 800 RPM ,and "should freeze there", but on early

ECU it resets, and repeats endlessly. (yes, that is A BUG!)

All years, a list of common failures:

- All

vacuum leaks for any reasons, are top cause. (hoses or diaphragms and

gaskets and seals) (remember that that 16v engine air leaks can case

low RPM (due to lean Air fuel mixtures))

- The engine is not really hot. Hot

is 180F or more ( legal thermostat markings are 180,192,195ºF) If not

hot?, the IAC valve will stay open

(the IAC is thermally

operated) and RPM extreme. The

IAC

water tubes most not be blocked in any way!

- Throttle

cables set way too tight, they must be

set loose

! TV is set to 10 mm loose (play or slack)

is the spec. stated in the real FSM book.(up

to 3 cables if transmission is A/T and with cruise option)The A/T page

in the FSM covers this, fully. page 7A-20

- The Throttle valve (TV) plate

not blocked

open by gunk on the underside. Clean it , and your cured.

- or the throttle body stop screw was fiddled by the "BAD GUY", on all 1991 and newer car. ( The cure is here, and is "NOT specified by Suzuki"; this is a hack to un-hack the bad guys bad deeds!

- Gaskets/seals bad (10 or more) or vacuum hoses missing,

cracked or connected

up wrong, not connected on one end (inspect them, find them) (injector

cushions on 16v leaking air?)

- The MPI main induction pipe (huge) aluminum or mix of

that

and plastic has seals, if any fail on 16v MPI engine, the engine

will go lean and idle controls may idle fail.

(due to unmetered air flow sneaking past

the MAF sensor!)

- Any Slave Diaphragms cracked (Brake booster leaks, or FPR or 8v Dashpot (DP) leaks. (The Dashpot is the fast

cold

start vacuum servo, with diaphragm inside)

- VSV valves leaking. (to

EGR or EVAP, DP) (vsv means vacuum

solenoid valve) (at idle, they are all off, if not?, fix that hard

failure first.)

- Is the ISC is just dirty? and sticking

so clean it? or the wires to it,

fell off?, or are corroded in its connector (cut ,damaged, mangled, or

frayed? wires) then fix that? first?.

- (EGR or ISC base gasket cracked, or missing?) EGR casings cracked, the 1996+ has 2 more EGR gaskets on that right side stainless steel side winder tube; do that leak air?

- Someone fiddled the bleed screw. to 8 turns out.?

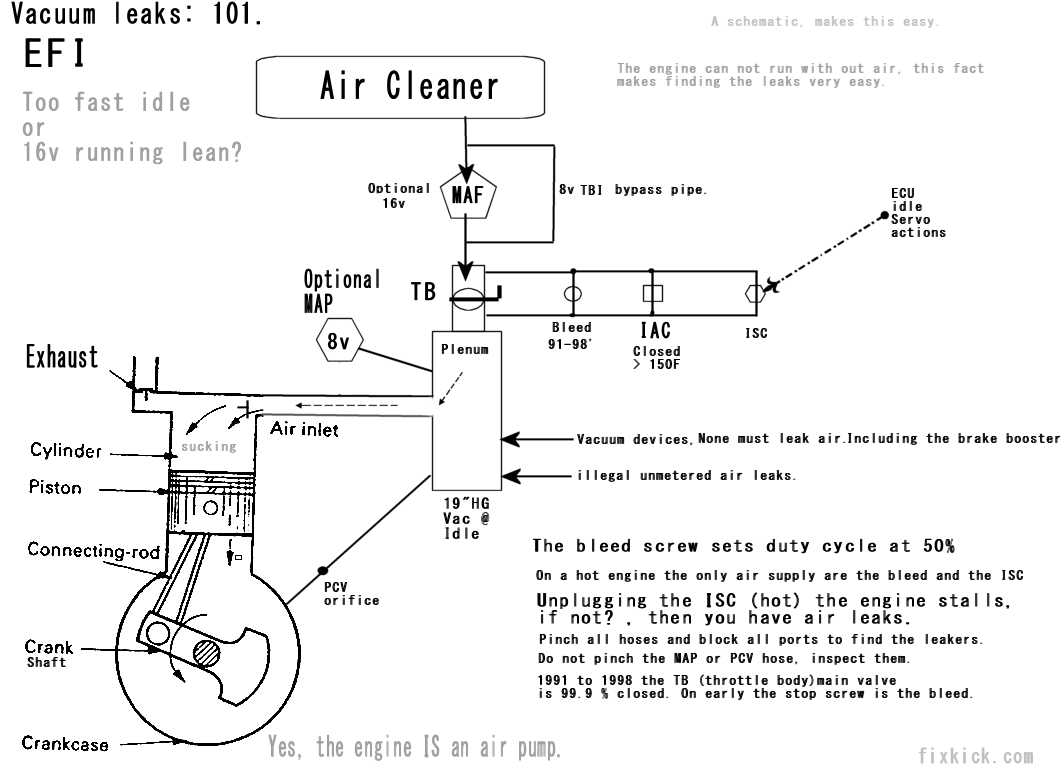

HOW to find all Vacuum air leaks on all G16s: (How to find them all)

(The natural plenum vacuum is at 20" inches HG {0.68 bar} a hard steady vacuum at idle and Aristotle said, “Nature abhors a vacuum.” on earth ,think how this works against you. )

The intake air plenum just loves to find air leaks and fail.

Normal conditions: (no leaker's)

If you have a high idle speed , we pinch the ISC air hose (the 91'+ has 3 hoses, 1 is cool , and 2 are hot (water) Pinch this cool air hose 100% the Idle must drop to about 400 RPM , or even stall. (only the bleed screw supplies air now) the RPM is the total of Bleed opening and all leaks, now.

This test above is the most powerful tool in your arsenal... to find vacuum leaks. (any)

The other trick is to defeat the ISC and see say 400 rpm, and then raise it via the bleed screw (400 is too low to do accurate testing) and then with idle near 700-800 do hose pinch testing now, if a hose pinch changes RPM, then it leaks.(fix that and recalibrate DUTY )

TO FIND AIR LEAKS, the best method is to defeat the ISC controls, or it may fight you during your testing. (aka vacuum leaks) (eg, you pinch a hose and the ISC hides the effect from you?)

I do the ISC defeat 3 ways: (or taking the ISC OFF LINE, killing it)

- The 2 ways, Pinch the ISC air hose, or unplug it. if

one acts

different (yes, that is a test too) then the ISC leaks air, if

yes, replace it or calibrate the ISC 5mm end screw, so it just tops

leaking air....)

- Defeat it by Turning the TPS body (base screws

loose) until the idle switch

goes to 5v, this UN-DOES the TPS

calibration , so the above

for me works better. (less collateral damage)

- In all 3 ways, the idle speed is controlled by me alone, and I can find air leaks 10x more easy, not fighting the ISC servo software actions, in the ECU, doing my long detailed , pinch tests (etc.)

| The 2 early years (pre -91')

have no ISC fresh

air hose to pinch, nor can you unplug the 2 wires to it

easy. (rule 1: setting duty cycle , destroys TPS

calibration these 2 years) (so I remove the ISC and use a solid gasket blocking all air in the ISC, The ISC wires share the TPS wires, so you can just unplug this connector. To do the pinch tests, I do that, and then turn the TV stop screw CW for good idle speed, (400 is not good "misfiring", closer to 800 good) then I pinch 89/.90 hoses looking for RPM drops. If you cure the leaks?, then the below linked pages puts the ISC back in to calibration. (TPS calibration is last, after duty cycle.) The 89/90 is very tricky to set up. See 2nd link below for why. 1989-90 only: Photo: Turn the Throttle stop screw, CCW until the (steps) duty cycle meter shows 50%? or set it to 50% now. ISC back on line... sure..! , |

DUTY what? (it sets the center point of ISC command authority) to 50%

Duty cycle calibration is covered here 1991 to 1998

1989/90 has not bleed screw so DUTY is set differently using this procedure.

If you can not reach 50% duty-cycle then you have gross vacuum leaks. (or ISC is just dirty or it leaks all by itself, needs re-calibration) (what I do is blow in the ISC tube and turn the 5mm until it's almost leak free.;it will leak a tiny tiny bit, let it) < my hacking....

Duty screw or BLEED screw: (keep in mind, the idle switch and failsafe mode, both can kill the ISC dead "software dead kills the ISC dead")

The 1991 and newer cars, have a Throttle body bleed screw, 8v TBI on front of Throttle body,

The 1992_ MPI 16valve, MPI is on top of TB, both engines bleed screws are hidden by black rubber caps (unless lost). (remove it)

end duty back to leaks...

HOT idle is out of control:

Say we now know, we have abnormal air leaks, a.k.a. Vacuum leaks. For sure, only where remains to be known. (some are easy and some can be confounding to find.)

The best way to find leaks is to defeat the ISC per above.

Some leaks only show up under higher plenum vacuum levels....

The 89/90 ISC must be removed blocked and tested , replaced with blocked passages (air) using a solid gasket made by hand behind the ISC mounts. (or defeat the TPS idle switch mentioned above )

Example1: More examples here

ISC Defeated:

In all cases, not 89/90' years, unplug the ISC or pinch it's air hose running, the engine many stall now, turn the bleed CCW, fully open or turn it until you get a nice RPM say 800? (too slow causes misfire, too fast is annoying) "you are on control now !"

If it stalls, then open the bleed fully or use a hot right foot cranking action, by that I mean add some throttle say 5% to start the engine, as there is NO AIR now to start. (very little or none)

So use 5% throttle ok, it starts. now, but may take more air to keep it running.... (use the BLEED to do that). (on the 89/98 turn the throttle stop screw CW)

Okay now the air flow is all a factor of BLEED + air leaks. (our goal is to find the leaks) use the bleed to get a comfortable engine RPM. (400 to 700 is too low, try for above 700)

Now the JOB, is to the pinch all hoses 1 by 1, (never the 8v MAP hose) any RPM changes are vacuum leaks found. "yell bingo" Fix that with a new hose, or find what leaks on the end of that hose and replace that. (PCV does leak a bit but never the hoses)

That is hard proof of an air leak.

Stop the engine, (key off)

Next, try blocking the brake booster, and plug that VAC large hose, with a cork , start the engine again same way, if the rpm is now very low compared to before the cork job., the booster diaphragm is ruptured. ( that means needs a new booster)

Try to keep in mind there can be more than one leak. (some of these cars are 26 years old now, and sure leak bad)

I even spray water on gaskets to see if RPM changes, and use raw propane gas near all sealing points, looking for RPM changes... if yes, it leaks. fix it. (the MPI has 16 places to check , gaskets and seals., more really , I can't count very high , lol)

Engine running ! (examples)

Hard proof of a leaks?

(The ISC defeated with its air hose pinched, or unplugged, wow it still races fast !) NOW !

If you close the bleed screw CW 100% the engine must stall. If not ,you have leaks. (CW = clock wise) << there is no air entering the engine, no engine can run with ZERO AIR supplied. (notice , this IS another test)

Lets say, idle is 1000 RPM. like this. I attempt to turn the bleed down to 800 rpm at least try, get it low as possible. lets say it goes to 700. (we have big leak with ISC and bleed blocked)

If you must restart the engine, with the ISC pinched or unplugged, I use about %5 throttle to start the engine or it MAY FLOOD ! on a new engine it will flood cranked, if there are super huge leaks it might start with no 5% throttle!

Adjust the bleed screw CW to lower RPM if too high now, to a nice idle now (not screaming or best you can).

Then pinch other hoses, 1 by 1 (to find if one is leaking air) RPM changes pinching hoses, means leaks (there), (PCV hose may might cause slight change , inspect this hose for air leaks)

Then pinch all other vacuum hoses. (not water, not huge induction PIPES) and never pinch the MAP hose (8v TBI only has it) hose. (we inspect MAP path very very carefully for damage and leaks)

In this mode RPM will be as you set the bleed, (ISC is off line now) but you can turn the bleed now so the engine runs smooth. and test the hoses.

Lets use 700 RPM as our example, Bleed max CW (screwed in and seated) , a hard failure example.

If the Plenum leaks air the RPM can be anything, I can't predict the flow of a random air leak, but do set the bleed screw to something reasonable for testing. now.

Some times the ISC leaks air and something else too, they add up. (if the ISC hose pinch RPM is not same as ISC unplugged (connector) not the same then the ISC leaks air.(it's bad or needs recalibration.)

Okay ISC is not leaking, I then pinch every hose in the engine (only vacuum hoses) lets say I had set the bleed to 700 rpm, and I find a hose that drops RPM to lower or stalls engine, well that hose is leaking some way.(find it , it's just one hose and a device on the end that can leak)

That is it !, that is all there is to finding air leaks from hoses, or devices on there ends. (next are gaskets , 10-16 gaskets can leak easy)

FYI:

Surging , can not be the ECU doing that (this ECU can cause surges) but not now with the ISC off line(blocked) above. All surging now is lean engine. (on 16v MPI engine , all unmetered air leaks can result a lean burn and surge. (with or with out ISC on line)

The hoses pinch are here vacuum hose and more. < See the X's in this 16v photo ?

The PCV valve can not supply the air needed to run any engine, but its hose leaking sure can. (exception is huge PCV valve someone used, off some Cadillac! engine, dang!, now that is silly to see)

The Fuel pump reg. (FPR) hose the same, inspect it. the 8v can be pinched, the 16v do not pinch it or fuel pressure ROCKETS high. Remove this VAC hose, leaking fuel is a bad FPR, then use a vacuum hand pump on the nipple. (words not ruptured cut off)

The brake booster hose is near impossible to pinch, stop engine, disconnect line cork the Vacuum side. restart, and may take 5% throttle to start. (proof others tried to hid this leak from you)

Flooding, happens on engines with ISC defeated, sure, there is no air to very little , on a good engine like this? so it floods, cranked, so use 5% throttle with right foot to start the engine, the fiddle the bleed to get more RPM !

If you flood the engine, then use 100% throttle cranking to clear the flood. crank at 100% for 3 second, then stop, key off and crank with 5%. now it starts, if it wants to stall still, add BLEED air (turn the bleed screw CCW) (bleed means air bleed duty cycle setting screw)

Okay all hoses seem good and test good, FPR good, VSVs good. no leaks.

The 8v FPR can not leak air to the plenum ever, but can leak fuel and cause horrid effects. The 8v FPR is for altitude only. The 16v FPR is connected to the plenum and is alway suspected of air leaks or fuel leaks, and 10x that after 20 long hard years of service.

The ISC test is easy,(if cleaned, the RPM stays the same with ISC unplugged or with its hose pinched, if it stays the same RPM , then the ISC does no leak air, other wise yes, it does leak air.(It can be recalibrate, gently with the 5mm Allen screw) CW a tad....

All tests pass above. (easy leaks)

Now harder to find leaks: (#1 way)

The IAC thermal valve, tests: Some IAC's leak air, hot and are BAD, some leak, because the coolant line is clogged (easy fix that)

Warning, do not run engine with MAF defeated or its PIPING system breached in any way shape or form. (or FAILSAFE mode rears it's ugly head)

The MPI 16v IAC intake port is a slot, we pack it in clay, to test.

The TBI 8v IAC port is here, seen with arrow, we pack that in clay, to test..

Lets say my defected ISC is still in force.(still testing)

and I have the Bleed set to say about 800rpm or with the bleed closed, it way be faster RPM, (can be what ever the leaks allow, the IAC flows METERED AIR ONLY (any flowing now via IAC will cause engine to scream hot)

I then block the IAC input port and put back my MAIN PIPING.. (it's ok to run the 8v with the main piping left off , testing, just don't let it suck in your glasses.... LOL)

I restart the engine and BAM , idle drops, way lower (or stalls) proving the IAC is BAD, easy huh? (or the water path to it , can be blocked, and was not really at 180F was it.??? sure not.)

IAC testing, the Alternate way #2: is to use bench testing. (just like you see how folks testing thermostats... no different at all , not really)

A Spare TB gasket in hand, (or buy raw gasket material from NAPA stores etc. and cut your own with an exacto knife, saving a fortune and 2 weeks delays from Exacto(tm)...etc...

The pan of hot water to test, you submerge the IAC in a pan of about 180F water (best) , then with a hose to your lips, check the air flow through the IAC ports. it must be blocked, (it closes a 150f and stays closed above that temperature)

Hint: closing the bleed screw 100 % can help testing here.

The 8v body I blow into its top air horn vent see in TBI 8v link above.

The 16v body I blow into the hole on the back side of the TB flange. seen here, on the right , see that brown stain, and red arrow this is the IAC air injection point, I blow here, cold and can blow easy, then at 150F I can't blow here.... )

Get the Tbody hot (IAC) then blow in that hole using any rubber hose, so you don't burn your lips, and wear gloves (garden gloves work great) Yes, it can be bench tested!

OKAY , the IAC is GOOD: (DON'T LEAK HOT)

We are now at the point, that we must have other air leaks. (unknown? as of yet) Those "DAG Gummed", Gaskets leak.

The 10 gaskets horrors. The 8v TB loves to leak here, due to the old hard center body gasket cracking then sucking in under normal engine vacuum.<< a hopeless case for idle controls. (can invade the bleed/ISC paths)

Bad gaskets under throttle body ? The slide show shows the kits?

The 16v has like 10 gaskets that can fail. . (head to intake manifold, and its tunnels to upper plenum. , TB base gasket, 4 injector cushion seals. , ISC base gasket, EGR base gaskets and on 1996 , 2 more EGR steel gaskets,) and more.

Manifold air leaks. somewhere. you have.

Finding it may take the usage of a smoke machine.? (Please Google this test, it take large skills sets, to know what leaks and which things must not..! even the tail pipe on the car will leak smoke, and all VSVs key off, will leak..)

The below shows a generic engine and some paths to leak air in to the Plenum by any means. The plenum is under a hard 19-20'inches Hg vacuum.

I check every possible way that air can leak to the plenum. (as you can see, it has lots of possible ways. Including some bad guy (1991+) touching the idle stop screw. or TB cables set too tight.

I spray water on all gaskets points, and seals, idling, (with ISC defeated so I can hear idle speed change) if it does change, that POINT leaks air.

I can play raw propane gas over on all those same points, and same deal, RPM changes, its got air leaks. (using a simple shop small propane torch; not lit) Be safe avoid liquid fuel tests here.

The lil' shop of horrors !

This TB or IAC or ISC can have freeze or ICE damage deep inside those parts somewhere and sucking air, in a place I can't go. ( found it by blocking the bottom IAC PORT AT BASE OF TB FLANGE.) ( very hard to detect this type of failure)

On 2 cars, both TBI the owner blocked the main TB air horn with his palm. engine still runs, now tell me how it can run with zero air.... It must not is the only answer. Doing so on a good engine, causes painful red ring on palm....so.... do so with great care, and use gloves.

The 8v TB (throttle body) has a large number of way to fail.... too many.....grrrrrrrrr

The 8v needs to have no leaks near X here.

The 8v bottom gasket MUST block these 5 small holes if not, it will fail !

The 8v gasket set must use the correct gaskets, seen here.

The 8v IAC sucks are at the IAC input port must not flow air , above 150F (blow with a hose to lips on this port on hot engine(the below photo is horn off to show failure paths more easy) see "IAC sucks here" below photo.

The 16v is almost a fail proof TB, just removable IAC goes bad sometimes or gunk under its TV fly plate (cleans off easy)?

The below is the wild and woolly TBI body base (8v) and loves to suck in that old hard brittle center gasket causing both the ISC to fail, two ways, the bleed path is now breached and the ISC output path. both fails cause ISC to fail, so a DOUBLE fail one part bad. (not found on 16v TB)

the old TB's have issues. gaskets bad,

and IAC on right leaking, or that white screw messed with.

the old TB's have issues. gaskets bad,

and IAC on right leaking, or that white screw messed with.To prove the IAC is leaking air above normal 180F hot engine, I deposit clay in the IAC "sucks here hole" .< (live testing) (Clay or putty , or electricians mastic putty)

If the 8v IAC leaks air hot, then the IAC under the words MIKUNI corp. is bad. (and can not be replaced, you buy a whole Throttle body to get this part working)

As you can clearly see, the TV is 99.9% closed with Dash pot removed. IT MUST BE CLOSED that much. (1991+) 8v and 16v. The 89/90 is a different animal. the bleed valve is missing.. and duty cycle is set at the no touch screw , those 2 years only.

MPI?

The 16v engine IAC can be removed (yah the screws love to seize). (finding one is no picnic, I had to buy a used good TB to fix mine,,,, hope you can find one easy) Suzuki sells them (if in stock) for over $1200 (or ? your next unborn male child?)

The whole induction system slide show is here. The 1989/90 ISC Secrets.

Other related parts are here.

I'm not doing cold engine idle speeds, the IAC does that and is about 1500 RPM cold, (move to Alaska and might be tad more) Testing the IAC (thermal air valve) is easy. (pan of hot water or blocking the air feed hole, to prove it's leaking & open cold !)

Air facts and theories: These data help when trouble shooting , lots of examples... are best...

See this test for air leaks?

Fact 1: Then engine can not start or run with zero air supplied. (EG on a hot engine, ISC hose is pinched closed with bleed screw , screwed CW in closed.) The IAC is closed hot. (the bleed screw is not nearly enough air to start and engine)

Fact 2: If the hot engine, you block (pinch closed) only the ISC air hose, the engine stalls or runs super slow as some really good engines, can. 400 RPM even. Do not remove hoses. This act defeats the ISC 100% even if IT leaks air, (bad)

If I was to only pinch the ISC air hose, and the RPM was like below, this is what I'd thank and do. (hot engine)? The ISC defeated also kills idle speed regulation that can hide leaks, we don't want to hide leaks ,while testing.

- RPM 400 , good. Calibrate the Duty cycle

now. I thank all is good. (no leaks)

- RPM 900 bad, you do have an air leak, so I next close

(CW) the Bleed screw (CW) now, does RPM drop below, 850 RPM to at

least 700 or lower is best, then the ISC duty

cycle can be set to run like this, do so...

- RPM 1200 or more, I'd thank closed the bleed, ok its 1100

now , I am sure we have air leaks here,(plenum)

or the IAC is stuck open hot. Lots and lots of paths for leaks to

happen, all cover on this 1 page.

- RPM 1200 and bleed drops it to 600, so I do the duty cycle calibration, now.

- I closed the bleed and the hose pinch (ISC) and RPM is 900 and more, you have gross air leaks. find them.

- Keep in mind at all times, if the leaks add up to over 700 rpm, (400 is my goal) that the ISC will not work right ever. (might every other day) and will not regulate the speeds under all conditions and for sure not in DRIVE (shifted ) or under FULL alternator loading (it uses 1.5 HP)

- Keep in mind , the ECU has 2 idle up pins, A/c on, and P/s overload that sets speed to 1000 RPM but not now, I have that defeated here. (the 89/90 has more idle up pins)

Fact 3: when the ISC is blocked, and worse bleed set to zero, The engine (sold new) will never ever crank and start, there is no air supply , so if this happens, use 5% throttle (hot foot it) and it WILL START I promise.

If this happens add bleed air, CCW (3 turns works) to get the engine started and get RPM up higher, (near 800, or 500 or 600 or 700 RPM so can test for air leaks.

On the other hand, if it starts easy and runs fast, there are huge leaks on this engine, plenum.

That is the best I can do with examples. hope it helps someone...

Fact 4: A new car, has only 2 air supplies, on a hot engine, ISC and bleed. just 2, all others are ILLEGAL air leaks. (illegal means , unwanted and catastrophic air leaks, not spec)

For the 89/90 car, change the word bleed to throttle stop screw, and CCW lowers idle now (opposite of 91+ bleed screw cars)

CW = clockwise

CCW , counter CW

Last of all (or first?) Is that ECU inputs can be wrong !, and idle controls can go off line, or not regulate.

Lack of air 101: (or too much)

The engine is and air pump, and when cranking only has about 3" inches, Hg ( 0.1 bar) vacuum and air supply. (weak it is)

On a cold engine the IAC is wide open and the the ECU sees its start pin, go high (12v) and then opens the ISC wide to add more air. (why?the MPI engine the MAP is useless for cranking as is the map sensor with 0.1 bar vacuum)

This means when cranking the engine, the ECU uses tables , guess at fuel rates, (yes, I said guess, after all the silly thing can't measure it , like it does running)

The ECU uses a table for cold and hot. (at least) and has known air flow rates, based on IAC open cod and IAC closed hot. (the ECU reads the ECT and knows the cold air flow, using ECT/IAC profiling.)

When the engine is hot, the IAC is closed, and if not, fueling rates will be wrong, in this case lean. (if the ECT reads wrong, all is lost here... a hopeless case.... if ever there was...)

Once started the MAF (or map) goes online (good air flows now), and like magic, the ECU now can read (or calculate ) true air flows (mass air flow) and inject correctly, based on true exact air flow facts!

As you can see, if the 2 air valves fail the ECU will computer fueling wrong. (it's is blind 2 both class failures)

There are 2 other errors here, fundamental. (not bad parts counts, but modes of failure with AIR)

abnormal metered air leaks. ( on both MPI or TBI engine, the idle races too fast ) ISC lost control, <<< examples IAC/ISC stuck open, bleed screw backed out 100%, TV valve stop screw molested. (not many)

and unmetered air leaks. (MPI goes lean, or TBI runs perfect but will race) <<< over 15 ways to have this, cracked hoses, and bad gaskets and cracked diaphragms. (or leaks in that huge top induction pipe, on MPI engines only)

On your TBI engine?, try to pull a vacuum hose running, hot, see it race? "scream" That is the MAP sensor detecting that leak and adding fuel perfectly to your leak, with FULL Horse power . (pinching hoses now finds leaks, RPM drops)

The MPI never do that. or risk lean run engine damage. (can overheat engine head poppet valves easy)

If the MPI was very rich and you caused an unmetered leak, it will race too (but that is now 2 failure modes at once,! )

As you can see, air leaks can cause hard starting (IAC stuck open hot engine ) and lean starting can be hard to pull off.

Lack of starting air, causes flooding , just like a clogged air filter would do...

The IAC stuck open will cause a huge hot IDLE RPM , over 3000 RPM. Keep in mind the IAC can fail 1/2 open. (failures have no laws, it does what the heck it wants, fate or rust , decay , entropy , whatever...)

The ISC must work too, cranking, if it is stuck closed the engine floods, cranking and wants to stall , if you start it with 5% throttle action with right foot.

Once started the ISC must work correctly, it keeps idle (hot) at 800 RPM, if you unplug it (2 wires) , it will close 100% and idle falls like a brink, all good engines, I checked this on , it falls to about "400 RPM". or stalls.

IAC is a thermal air valve (closes at 150F (65C) if not big trouble you have..

ISC is the electromagnetic , air solenoid valve. (or idle speed regulator device hot) it has other uses running besides that.

Best tool to have is the DUTY meter. that really does work (many don't I've tried them...) The $400 FLUKE(tm) meter does work but is $$$$ serious cash.

WORKS 100%

The MST-2800B (ebay) see in last photo here.

Set the dial to DUTY

Connect the 2 leads to the ISC pins (back probed) hot engine, accessories off. turn bleed for 50% done. (use back probing needles, at idle.)

See my scope match this fine $25 tool.

ECU pins that can upset idle speeds: (with real FSM pages linked)

My schematics pages and ECU pages cover which pins. (the ECU is a computer and inputs set wrong can upset any ECU in ANY CAR)

Scan tool shows no live or stored DTC errors.

Flash codes are 12. 12= I'm ok but gee I'm (ECU brain) too dumb these years to really say.....or know...

8 Valve TBI engine:

(The G16a 8v TBI pin outs and voltages are all stated here)

The G16a full pin voltage list PDF is here. (best list in one file)

16 valve engine MPI G16B 1992-1995 ECU. (as seen here and the logic rules. off my ECU + critical pins page) Page1 and Page2

KEY idle fail PINS: 16v Gen1 years. G16B. MPI engine 92-95.

A2 in wrong state (means not at 0volts.) per the linked page,

A6, on DLC pin, bad at 0v, 12v is good."test switch term" i call it timing freeze. test jumper lift in place? or wire is shorted to body of car.

A17, jumper Diagnosis left in the connector? 0v wrong. or shorted to car body.

A18 , idle switch is closed.? 0volts? DC.

A19 , P/S overload, 0v = fail

A22 , tells the ECU that you are in shift selection drive.12v now is a lie. 0v is correct. if at 12v the ECU uses a very powerful idle up duty cycle.

B7 , Throttle angle near about 1vdc

B8, MAF not hear about 1.7 to 2vdc?

B9 = 0.65v (means 180F temps now hot engine) higher is bad.

B20, (it's a fast moving 02 signal, and if way off voltage or stuck, the engine can go rich or lean, a scan tool shows it working or not...(or any scope) and when swinging fast is called closed loop.

B21 is IAT, I think this is not important here. what is ? 1-2v or so, depends on air temperatures. Some years MPI engines have no IAT at all. (1992 !)

Thats it for ECU , inputs that can lie and cause problems with idle controls.

A test for induction air leaks:

Test Conditions.

ISC defeated (off line) test, Pinched ISC hose or unplugged ISC elect. connector. (do both to see both have same RPM? if not the ISC leaks) Title, Bleed data.

This is just data from one G16b 16v engine.

BLEED screw data: from open fully 8 turns CCW and then closed fully CW.(stalls)

HOT engine, (IAC is closed hot) I did the IAC leak test first,. proving that it is 100% closed at 180F. (if not the below always fails)

ISC off line.

data: "empirical evidence" (IAC CLOSED, ISC CLOSED)

bleed screw settings: (we do this to find air leaks!) (only the bleed is or only air supply below) A Test: (using the worst tachometer ever made, the cluster gauge is a toy) This is not scientific due to this fact, but is real world testing... (no quality tools in shop)

0 turns engine will not start, nor stay running, unless you use a hot right foot to start it (5% throttle) (engine has zero air now) then once started, removing said foot, stalls it again, but you keep it running all day , with a happy right foot. (called "Feathering" by many)

1 turns out, We got 100 RPM and stalls. (the dash meter is inaccurate below 500 rpm so this number should say 100-500) Engine shakes. (and may take hot foot actions)

2 turns= 300 ( runs but might stall, and most engines will shake,(shake means misfiring seen and heard). 300 is too slow for most engines to run right. (some will run at 400 rpm and shake)

3T= 600 rpm (runs) (in all cases the throttle foot might take 5% throttle get a start to happen.

3-3/4T = 800 rpm (great place to do pinch testing of hoses, etc.

4T = 1000 rpm

8T turns nets 1500 RPM (the test is best done , starting from here, and screwing the bleed down, counting turns and results an the stalls rpm noted) It amazes me the bleed has this much range of authority.

I believe this test engine above shows no illegal air leaks, because we can stall it with the bleed screw easy. (but oddly the person doing this test can get DUTY below 57%)

( above was not done with a real digital accurate tachometer, only the factory dash "toy grade" tachometer, mostly it is useless to use for accurate engine diagnosis. ) I do find it effective in most case, how ever...

YMMV ! your motor may vary.....

rev 11 ++++ 3-9-2015 12-4-2015, major REDUX1, one page, with only some links to dutycycle calibration, steps by year generations. Gen1,2,3. and pinch testing. , water spray tests, propane gas tests.(full PPE)