How to time the distributor, ( aka: The Dizzy!)

Suzuki Sidekicks or Geo Trackers VIN “U”, 1991 to 1995. 8 Valves TBI

If your motor is a 16valve motor or Tracker VIN “6”. Jump to the 16v procedure page.

The page is long, because is shows how to do this from a disassembled engine and how to correct the 10 crazy ways, of doing it all wrong.

How to install, the removed dizzy, fast.

Fast track, no mad PO’s, no slipped timing belts, a daily driver. (we do this, after every tune up)

Assumptions!

Fast, fine adjustment list:

1: A Hot motor (180f degr. minimum) running at idle.

2: Connect Strobe timing light to #1 spark lead

3: Idle at 800 RPM (if not set it now) (TB idle bleed screw)

4: Set the Freeze jumper. (a paper clip) conn. just in front of the battery.

At, Jumper D to C to freeze timing.

Check timing?, now, at 800 RPM idle.

5: Point that Strobe light at the timing scale and see it at, or adjust it to, 8 Degree’s Before TDC (left side of zero scale mark) (see your hood sticker or exact timing)

if just tad off (1deg?) then adjust distributor base, if way off? then the timing belt has slipped, if true, do not touch the distributor yet, fix belt first..

The 60k tune up is the avoidance of belt slips.

If way off?. do the Tbelt sneak-a-peek check.

The below covers every possible way to mess up spark, over 10 ways… or you rebuilding the engine and head.

This pages assumes you know how to use a strobe type ignition timing light, and that you know, the Dizzy spins Clock wise and the crank spins Clock wise (looking at pulley)

And that the markes are clear.

You are here because your:

- Ignition timing is a tad off. like 5 º or so. Just do my fine tuned dynamic, Timing Light section, below.

- Tming is way off or as much as, 180º off. Just do the Course or Static timing test, (someone spun or removed your distributor?)

IF your cam timing belt stripped, then you must correct that first.

If car runs pretty good, then jump to the FINE TUNE procedure, HERE.

There are 2 timing procedures. Coarse, sometimes called Static and then the fine tuned method.

The worse case method is, install the Distributor physically, and clamp it down using the coarse section below.

The coarse adjustment will be about 5 degrees ± accurate when done, and the car will start and run pretty good.

Later, you get a timing light and set the timing exactly.

The coarse adjustment: ( the adjustment done,before the final final fine dynamic timing procedure, last)

This procedure is done not running using only you eyes and is called Static timing.

Optional step:

Consider replacing both the Distributor O-Rings on all high mileage Kicks, before doing this procedure, using Silicone grease. ( or leaks can happen)

The Main Housing to the Head O-ring, loves, to crack and then leak oil all over the back of the engine and down to the exhaust pipe.

WARNING: If your motor is a 16valve motor,Go to the 16v procedure.

Do not read the Haynes books on this procedure they mix up the 8v and 16v motors in a toxic soup of dis-information.

If someone did the following to your distributor you need to do the Static timing procedure, if the motor runs, use the dynamic procedure.

- Removed the distributor for any reason, use Static method below. (valve job, new head gasket? or?)

- Loosened the distribuotor and spun it willy nilly and car don’t run right then start with static method. Tell them to go to school on EFI.

- Some goofy guy inserted your distributor at TDC and the rotor falls between 2 tower positions, no matter what you do then do static method.

- Some one looked at the Haynes and layed the wires down backwards. Sigh.

A running engine:

If you are just replacing cap or wires, then just swap one wire at a time or mark every cap port and each wire with a tag.

1, 2, 3,… Done!

Worse case, it is best to mark everything for most Distributor work:

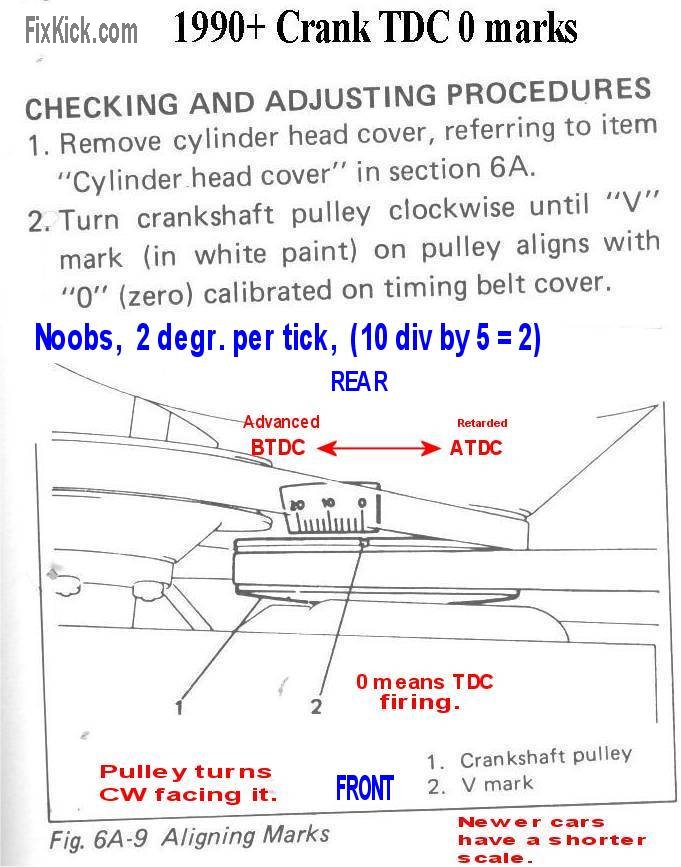

Set the Crank to TDC 0 deg. Cam at TDC #1 cylinder firing, and all #1 Valve lifters are loose (all #1 cylinder valves closed fully).

(blow air into #1 cylinder spark plug hole with any new rubber tube with lips, if you can’t blow, then the valves are closed. YOU are ready)

The same trick can be done with a cylinder compression gauge (as the FSM says to do).

| PreStage: Engine tear down,new head, new distributor, or new Distributor o-rings? then PAINT some marks: Lay down 4 marks: You must mark at least mark #1 wire. and the cap position for #1 cylinder. On the cap, the casing and inside the base plate. Like this.(some 8V caps can be installed backwards, but not my 91′. ) One last mark, put the cap onto the Distributor and mark #1 on the cap and a #1 slash on the Distributor side, just below #1 cap terminal post. Then one inside on the dust plate. Last mark the Distributor base bolt center line, on the outer base flange. ( doing all this can assure 1 degree accuracy on reinsertion of the Distributor later)Later, this Distributor rotor rim mark will be used to get the Rotor pointer aligned correctly. Some rotors can be installed 3 ways, buy a rotor that prevents this bull. Buy a NGK, or Bosch or Denso, Beck, Delco, or other good rotor. |

If someone timed the distributor to the 1pm or 4pm or 7pm location then you are on your own, if you wish to do that too.

HV= High Voltage wires.

ALL STEPS: (worse case, Valve Cover attached) (OEM method)

If you know the distrirbutor has not been removed then jump to step 14:

- Begin crude static ignition timing setting procedure.

- CAM timing is NOT OFF!!! if off, this procedure is a waste of time and effort. CAM DRIVES the Distributor.

- At this time the Distributor is pre-staged and maked, as per the above box.

- Set the crank shaft to #1 firing position 0 Degree mark (see cam cover gage?) by either using a compression gage or removing the valve cover and looking at #1 rockers for being loose ( you did set the valve lash, right?) Both the valves of #1 MUST BE CLOSED, if not Rotate crank 1 more turn, CW (facing rear). Use a socket wrench on the crank end [17mm]. I recommend putting a Compression gage on #1 and watching it, as #1 comes to TDC ( you will see a high reading, if not, 1 more turn CW on the crank, ok?) [FYI: the valves are closed when the tappets adjusters are NOT touching the valve stems, in fact they are loose ] One can take a simple spare new rubber hose and blow air into the number 1 spark plug hole,to discover, if all the #1 valves are closed. (I use my lips, no big deal, just dont suck)

- (this is very simple to do, no new valve gasket needed, and is almost a free tool ) if your cheeks puff out, then #1 is on the firing stroke and this is EXACTLY what you want. If air blows in easy,then you are on exhaust stroke, so please rotate the crank 180 Degree’s again. Repeat, this blow test. Ah, #1 firing at last.

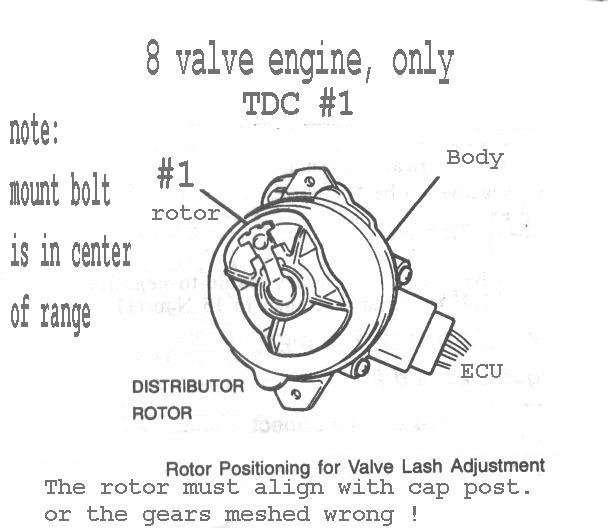

- Ok, the prestaged Distributor is in your hand. Put the rotor about 1 quarter turn before 11pm (11 o-clock)

- We will place the Distributor into it home, next, as shown in photo, below.

- Pour 1 teaspoon of oil down into the Distributor base (I assume it will be dry?, into the Distributor base, where that Dizzy bottome end gear goes.)

- Insert the Distributor turned a 1/4 turn CW from 11pm, #1 post (anticipating the action of a curved Distributor gear)

- Push the Distributor into its home and notice the rotor has moved to the CCW and comes to the final resting place, as the photos shows. < TRICKY huh?

- Repeat this until the base mount adjusting clamp bolt is in the MIDDLE of its range.(bolt loose) (at 0 degrees crank pulley indicator).

- See OEM 8V written procedure. Keep inserting the Distributor, so wire #1 Cap position aligns perfectly with the Rotor pointer AND the Bolt on the Distributor clamp is perfectly in the center of its slot area. This finishes Course or static Distributor timing.

- Having put paint marks on the Distributor out side case for #1 plug wire really helps. Clearly marking 11pm for the rotor.

- The rotor metal tip is now aligned pefectly with the #1 cap tower terminal! TDC #1 FIRING.

- Tighten the Distributor clamp bolt. 5ft/lbs. or so. (we will move it later with the dynamic timing setting procedure below.)

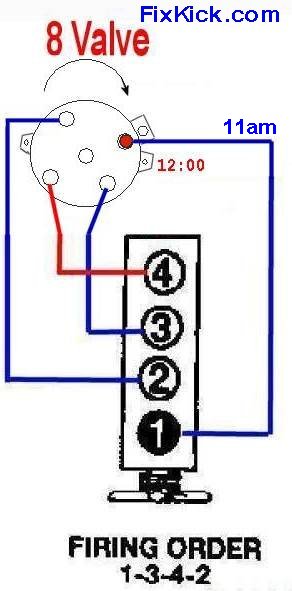

- Put back your cap and wires per below ordering, and car will start, be sure to use the correct wire order and rotor direction per below photos.

- The is a CW spinning rotor. Ignore all other books to the contrary (the Haynes is wrongl the FSM is proof!)

- Start the engine, and proceed to the next fine tuning procedure, below.

This act is standard procedure for all cars with a Distributor, that is gear driven.

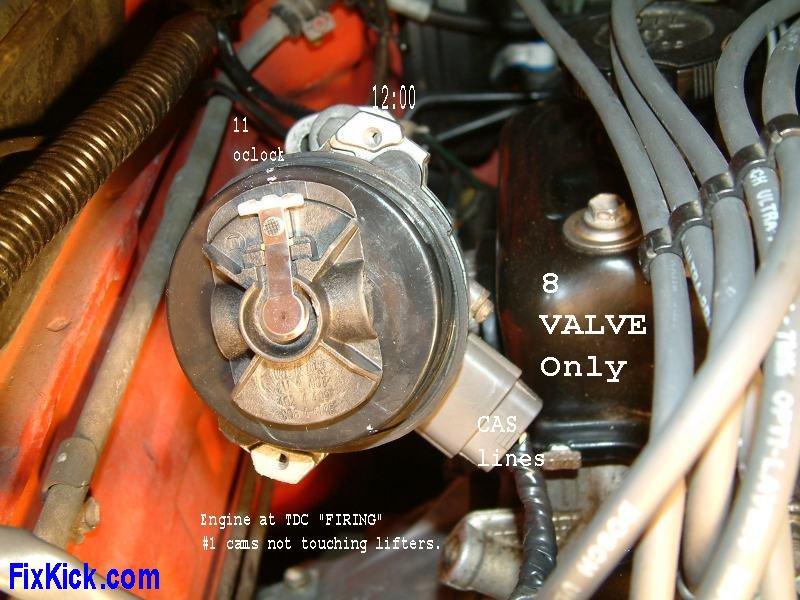

Here is an actual photo of a working Distributor in my 91 SideKick below Parked at TDC 0 degrees, #1 firing!

#1 cylinder firing on the compression stroke TDC = 0 degrees. ( can’t get much clearer photo, huh?)

Some parallax distortion, due to the firewall, being in the way of camera.

The BELOW, IS For a 8-Valve engine only. Photo 1:

The above is for 8v only, with clock wise rotation, Firing order is 1,3,4,2. 11pm is cylinder #1

The Proper Ignition Setup.

Clamp bolt is straight up. The Clamp bolt is the most important, reference point.

Drawing 1: (8v only )

If you did the procedure correct above, the car will start.

If not, check your work carefully.

THE FINE TUNE, TIMING SETTING Procedure:

After a tune up, I make sure the advance can walk off the timing scale, over 3000 RPM (mine goes to 40d BTDC) “Strobed!”

If it can not do that, the ECU is stuck in LIMPHOME MODE.

Also Known as : DYNAMIC Ignition timing procedures.

You need an electronic strobe timing light. (buy, barrow or rent one).

Before connecting your timing light: (look up, the timing values, which can very by year)

Set the this diagnostic Ignition FREEZE jumper now.

Preconditionals:

- Run the Engine until fully hot. ( 180F minimum COOLANT, and near a 800 RPM IDLE)

- A/C off, Head lights Off, defroster off, FAN off, all accesories off, except the IGNITION.

- Set the Freeze jumper per above link. ( you may need to stop and restart motor )

- This Action tells the ECU to freeze the Ignition timing. “Otherwise, if it bounces like crazy” See comments at the end for Bouncing issues.

- Set the Idle to 800 RPM HOT via the Throttle body Air horn bleed screw, here.

- Connect the timing light to #1 spark and point it at the crank damper pulley and the lower front Timing belt cover.

If the timing Feeze fails?, then read this section carefully

+

Connect the timing light power wire clips to the battery, red to red,black to black.

Clamp the Timing light,inductive clip to #1 (FRONT) spark plug high voltage wire. (the sparkwire).

Using a electronic timing light set your timing by moving the Distributor base just a tad. Set it to the mfg, specifications.

Again, if the timing wiggles by itself, the ECU diagnostic jumper in front of the battery has the jumper set wrong, or other input to ECU is wrong.

- The Distributor has a clamp bolt, loosen it a tad, rotate the Distributor just a little and the timing marks on the Crank pulley will move in relation to the Timing belt cover. there is a tiny scale there. 10||||5||||0 (hard to see black plastic ) Before TDC, is to the left). See it?

- Paint the timing marks with “Liquid Paper (® )” the Crank and the 8 degree hash mark.(as appropriate)

- Move the Distributor until you reach the below timing value and then set the Distributor base clamp tight.

- You Distributor is now perfectly timed.

- Lock the Distributor clamp down to, about 6 ft/lbs.

- done., remove the jumper!

Spec. History:

Timing is 8 deg. BTDC ( before top dead center) [ early Kicks ]

In 1996 the Timing dropped to 5 Deg. BTDC, up to year 2000.

RPM is 750- 850 starting in 1996 to 1998

RPM is 700-800 1999 to 2000

BTDC = Before Top Dead Center (firing, NOT exhausting )

Supporting Photos: (OEM method) 3 more alignments can function, but this is the official way, from Suzuki.,

Drawing 2: This is the factory setting. (FSM actual )

The Freeze Jumper does not work, my timing keeps jumping like crazy. The ECU sees a FAULT.

The ECU normally bounces timing all over the place, at idle, this allows better fine tune of idle speed and best economy, (ECU brains that so well)

We freeze it so we can see the true STATIC timing. If it fails to freeze, here is why.

The problem is real and common.

The following failures will cause this problem:

- TPS switch is bad or not closed at idle. (simple TPS calibration is easy) set it for 300 ohms or less. A COMMON FAIL.

- The ENGINE is not HOT, the themostat is bad 180F is the spec temperature of the coolant or Hotter.

- The A/C switch is signaling High Idle falsely. (turn off the A/C or repair the switch as appropriate, the A/C lamp MUST BE OFF)

- You Automatic Park/neutral switch is failure, signaling IN GEAR, falsely ( theory).

- You RPM is not close enough to 800 RPM to make ECU happy ( fact but how far off can cause freeze to fail is unknown).

- ECU is faulting, forcing Limphome or BackUp mode, no idle controls in this mode. (first repair all ECU input devices.)

- You have Accessories on, turn them ALL off, A/C, Fan, defrost, AUDIO stuff all off. NO ELECTRICAL LOADS, besides Ignition!

- The CEL, Check engine lamp is on. Repair the car first before trying to fine tune the Ignition timing.

- Power steering high idle switch is signaling PS pump overload, falsely. (bad pressure switch) [rare]

More photos for 8v.

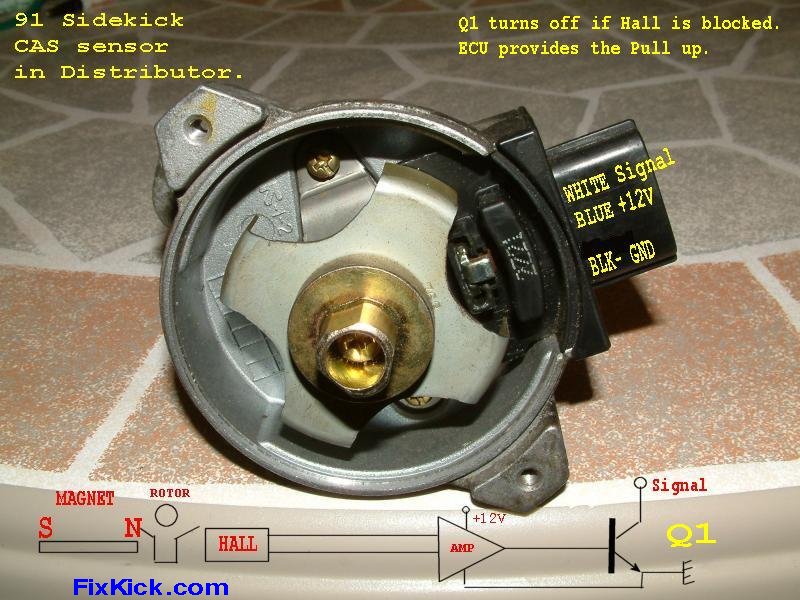

The CMP is the precursor to spark, it is the drummer boy that starts all spark creation and injection timing.

Some times Cam Position sensor or Cam Angle sensor.

If the CAP rotor is installed wrongly, using 2 of the 3 ways in error, the below 4 Star Hall reluctor will fail. See why?

The SUZUKI spec rotors can not be installed wrong, If your ROTOR does, it’s China NoNAME JUNK. Get rid of this tripe.

Photo 2: This 8v valve G16A engine sensor almost never fails. It produces a 5v square wave.

The actual CMP HALL sensor

The actual CMP HALL sensor

Drawing 2: the spark timing scale.

Drawing 2: the spark timing scale.

Fast Dizzy planting 8v. (for 89/90 see here)

(firing order is 1,3,4,2 on all 4 cylinder kicks, #1 is front)

There are 4 ways to time the distributor, the below is the FACTORY way. (all 4 ways work, but I’m not covering all ways)

You are here, because all timing was lost, for the Dizzy (Distributor)

Factoid 1: The engine fires every 180 degrees of crank rotation. CW is normal rotation facing rear of car. CW means CLOCK WISE.

This section, is a short version of this: (the below, is short, as is possible)

- Set engine to TDC 0 degress #1 firing, the valves on #1 (front) cylinder must be loose, that is, lash is loose, if not? turn the crank 360degress CW, See mark 2 above, at 0?

- Are you at DTC #1 firing? now? good. if not repeat #1 until it is.

- Drop the dizzy down its hole, with cap off and rotor present (no China clone job rotors allowed, use the real one) and note the rotor location.

- The rotor spins, in your hand, as you do the drop. This is normal for all helix spiral gears, what you do, is anticipate the rate of the rotor movement, and make the rotor land on 11 AM.

- See drawings 1 mine, and drawing 2 (factory) this is the correct location. NOW, lock down the dizzy base screw.

- Next, mark the cap so that #1 is marked on the cap aligned to rotor tip, then lay down high voltage HV spark wires seen in Drawing #1

- Connect coil HV lead, to center the cap center terminal.

- The engine will now start and run, last step is timing with a strobe light.

Factoid 2: If in number one, you don’t want to remove the valve cover to watch the valve action, you can remove spark plug #1 and blow into #1 and if can’t blow, it’s firing on #1 (the blow test )

Yes, use a CLEAN hose and lips to do that.

RELATED:

O-Ring data: see Oring sources and part numbers here.

Assumptions: (PO = Previous Owners)

- Cam is timed correctly, if not, this whole page is useless.

- The Dizzy gear is not put on upside down or 180 degresses off. (PO hacking?)

- The CAM gear rear is not indexed wrong, some are press on gears there an index mark here. (PO hacking?)

- Someone put a POS China knock off Rotor on the Dizzy and it fits on 3 ways, SORRY that is NOT STOCK, no stock rotor does that, FACT! BOSCH FITS, for SURE.

- The HV wires are not laid down backwards, reading the GM (Geo) and Haynes/Chiltons books, all get this wrong. for 22 years in a row and no edits YET. (Suzuki real books are all correct)

- Valve lash set to spec, so you can see the gap there, and see that #1 is firing. If not, FAIL you will. (2 ways, timed wrong, and if it did run, you get to burn the valves top a crisp)

- The infamous, crank cog is not sheared.

- You used the freeze jumper, per the book and here.

- There is spark is great, out of the Ignition (induction) Coil. “the Mr. Tesla magic”

- Cap and rotor not carbon tracked.

- HV spark wires dead, open or insulation long ago, failed, No spark plug wires on any engine last the life of ANY engine. period. It’s called a tuneup.

- Spark plugs fresh, not black as an ace of spades.

I’m sure I missed, something…

i started with car overheating bypassed heater core, replaced timing belt ,both belts and pullys, water pump then alternator {belt to tight). then new wires,cap rotor..cranks but no start 1992 geo tracker made in canada..HELP.

ACTS LIKE TIMING OR NO FUEL GOING THREW .SMELL GAS THO