This engine is and under stroked J20 engine. (a different crankshaft) (see this text file on motor facts)

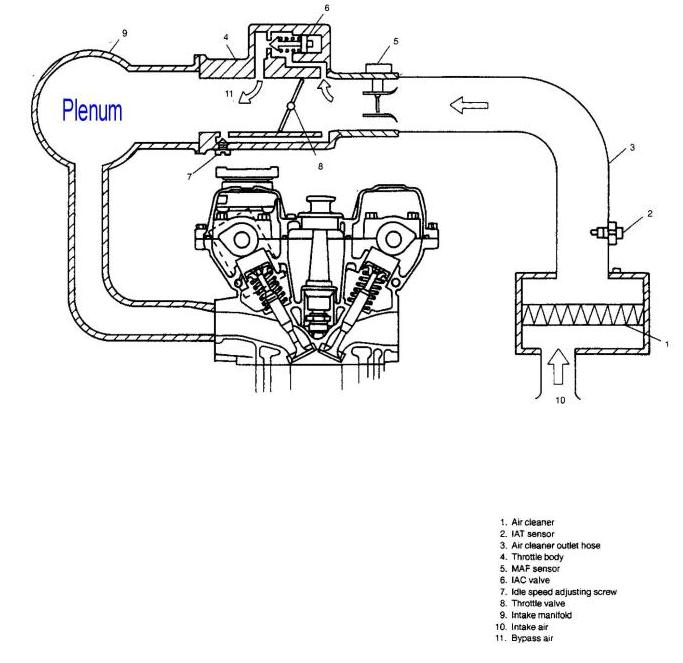

The engine looks similar to this J20 set of parts.(< ignore the MAF location seen here in .pdf)

Cleaners, I use only brand "CRC MAF" cleaner on all devices containing plastic, (ISC, EGR, etc)

As with all OBD2 cars, you can in fact do a full scan with any $50 scan tool and see if the motor or EFI is sick, that is bad sensors. or dead closed loop at idle.

If the motor can't hold closed loop and goes way lean , the idle will drop, and surge (hunt) all lean motors do that, not just this J18.

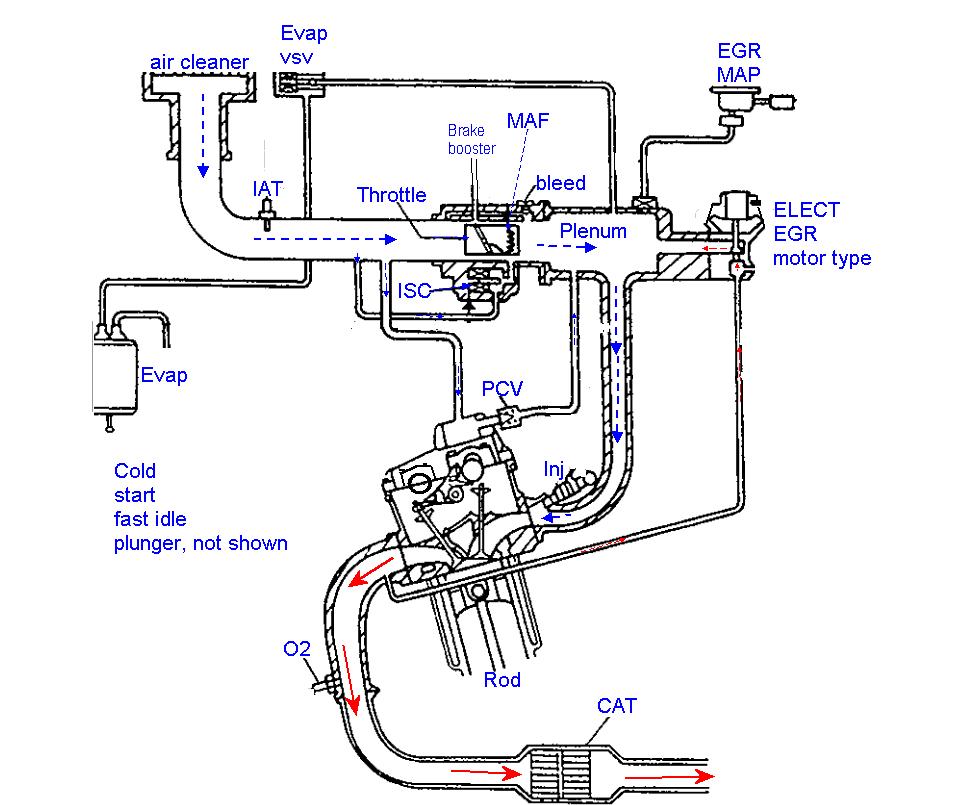

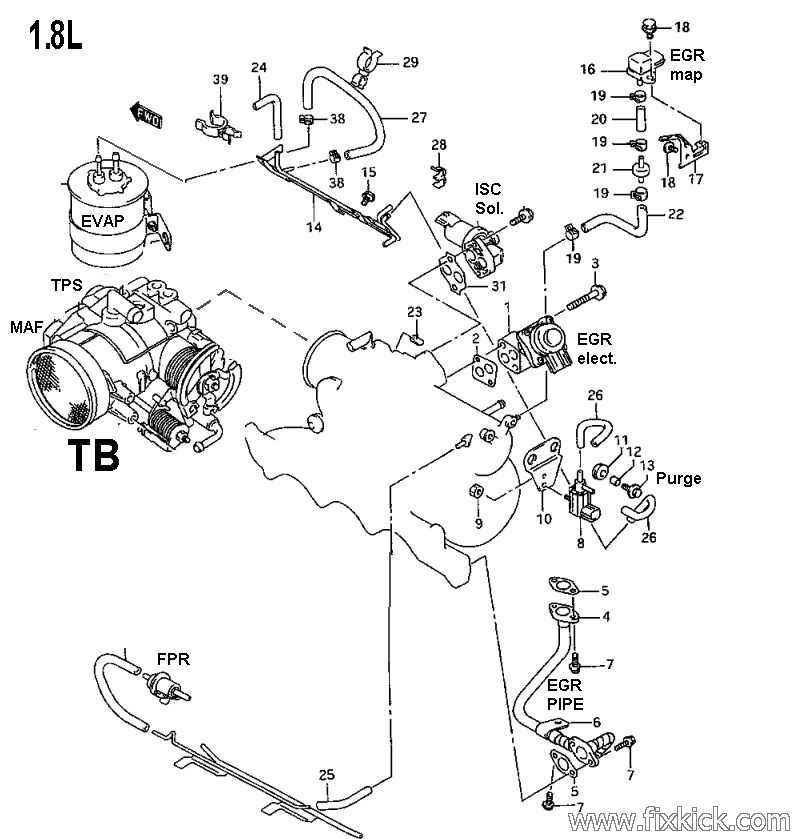

The 1.8L has the MAF sensor (air flow sensor or meter) located not in the air cleaner but on the side of the TB (throttle body) so air leaks up front of this point don't cause bad AFR (lean) like on G16B motors.

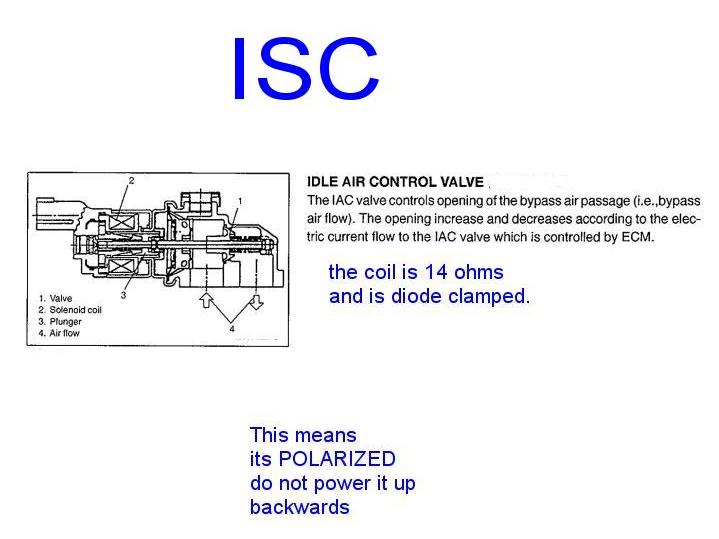

The ISC is moved to the right side of the plenum (drivers perspective) just in front of that pesky EGR main valve. (the 1.8L has just one EGR part to mess up)

Suzuki added a Diode clamp to the ISC coil to protect the ECU, try not to burn it up, doing hot wire tests. (FSM covers that step clearly)

The lower limit on compression test (cylinder) is 170PSI, spec. is 199 PSI.

As with all suzuki's if the gas cap is missing the vacuum breaker?, the fuel pump will stall and power drops and the engine stalls, even at idle if ambient temperatures drop.

This page is steeped in Jargon. , about 30 terms.

If the engine runs bad, all this is just a wasted effort.

Engine, misfiring, bogging , flooding, shaking at 800 rpm hot, lean engine, too rich, spark plugs fouling, etc..

if it runs ok, next we can do these steps.

After OBD2 scanning the PCM.

First make sure the CEL lamp is on , at key on , and goes out running, if not, correct those issues, first.

Low idle and stumbling, is most likely claused (skipped the 50k mile service, huh) the EGR stuck and leaking exhaust in the intake (plenum) at idle. clean it and service it.

The 1.8L TPS has no idle switch, but when the TP pin goes to 0.5v , (± 0.15v) < Calib.

You get idle controls, (a very simple rule here) pin 2 gray. (this is the only calibration on the TPS,)

The idle bleed screw on top of the TB , just like the 1.6L (under a plastic cap) to set idle to 800 HOT.

As with all EFI systems, air leaks to the plenum , regardless of source will kill idle controls , beyond a tiny tiny leak. On this engine plenum air leaks cause too fast idle cold ,and low idle hot (due to lean bogging).

Air leaks here, are un-metered air, that is, the MAF never measured this illegal leak!, so fuel is not added to match it and the AFR goes lean (Air fuel Ratio). Simple as that....

The idle System schematics:

See here for full EFI system view.

Motor good, spark good: (is the predicate) not in limphome mode (use a scan tool or guess wrong!)

Leaks and such.

- Scan the PCM, fix all DTCs first seen there. The CEL does not glow for all ERRORS and even less in CANADA.

- Throttle cables slack must be 2 to 7mm (spec) measured at

the accel. pedal. with hot motor, IAC plunger retacted.

- ALL leaks to the Plenum are bad news in this motor, causes lean air fuel mixtures and low idle.

- Inspect all vacuum hoses connected to the plenum, for cracks or hoses missing, fell off, or routed wrong (open hood , look up see vacuum map, check that first)

- Pinch all the lines, if idle changes, that path is faultly. (do not pinch the PCV, just physically inpect that hose to the Plenum.

- Make sure the injector cushion seals are not cracked, if they are, they suck air like crazy ( I use propane gas near all suspected leaks, idling to see if RPM changes, lacking a smoke machine)

- The EGR must be closed at idle. (clean it )

- Make sure the MAF reads 3 to 50 gr/sec using a scan tool, gun the engine see 50grams. flow. if the MAF is dead, the ECU runs in limphome mode, a mode that shuts down idle controls.

- The 1.8L FSM states, that a bad VSS can also , evoke

limphome mode.(while driving)

- Block the brake booster hose (do not drive like that) just see if the hose leaks, I do a vacuum hand pump vacuum leak down test on the booster.

- Bad gaskets under the EGR MAP, ISC, EGR or Injectors will

all cause bad idle or lean idle. (as will all plenum gaskets failing or injector cushion seals)

- Any hose connected to the plenum not mention yet, that to

must not leak air.

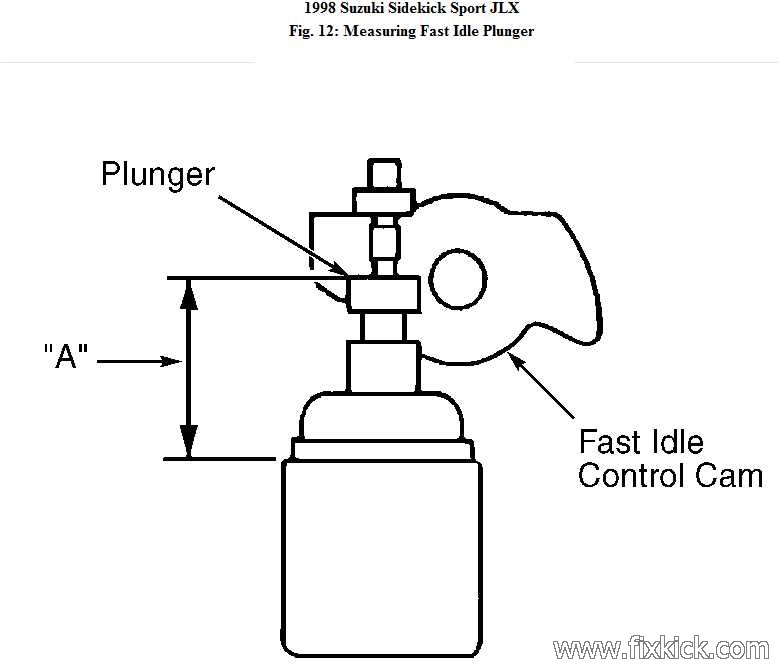

The 96-98 1.8L SPORT DOHC Throttle body has a cold start plunger device (thermal). see photo below. Make sure the PLUNGER extends out 1 inch , below 77F and holds the throttle open (use penetrating oil on it and grease the linkage.) Lack of air starting will make starting hard. and a very slow cold idle and some flooding. If this devices sticks open hot, the idle will never be 800 RPM. it will be real fast , 1500 or so... |

At this juncture we know what? Good motor, good spark, no air leaks, EGR not stuck open, plunger is retracted above coolant temperature 154F.

We now attack the other idle devices.

- The throttle plate is stuck open, it

must not be open at all, it must be 99% closed. (look for gunk

under the plate blocking it or some silly pervious owner playing with

the throttle stop screw. (correct this now)

- Someone fiddled the Hot idle speed air bleed screw on the as seen below? , then try to raise/lower idle.? to 800 RPM hot, no accessories on. If you can't, there are air leaks if CW seated, the idle is above 800.

- If idle is still wrong, and no air leaks found , then ISC must be bad/dirty. (the FSM offers 2 tests for the ISC) see below for that.... The ISC is and electric ECU controlled solenoid air valve.

The FSM ISC checks.

The FSM states, this:

You can unplug it and measure the coil with any ohm meter, if it reads below 14 Ohms , reverse the test leads, and try again, if now 14 ohms (or near) its a good coil , if it reads infinity its always bad.

Unplug the ISC , running the idle must drop at least 300rpm if not , its jammed up. clean it.

Now the tricky part, in the FSM.

They have you hot wire (apply 12vdc ) to the solenoid coil (for sure disconnected, never hot wire any wire to any ECU)

But the 1.8L ISC has a diode clamp inside, that must not be blown up.

FSM quote on this tricky test.

The ISC has 2 pins, and is 14 ohm coil inside, unplug it and idle drops, say 300 RPM , ISC sits in front of the EGR motor driven (main EGR valve) Rigth side of the Plenum camber.

The ISC can be hot wired, but has a diode clamp in side; if connected backwards it blows up (see FSM warning)

To hot wire the ISC, Ground ISC pin 1 (lt.-Grn-Blk) and put +12vdc to pin 2 Blu-Blk and idle will go real high. (read carefully)

Suzuki calls this the idle speed control valve. (ISC) It works just like the G16B engine. (with an added diode)

FYI:

ISC coil , some books show a reading as low a 8.6 ohms and upper value of 10.6, others just show 14 ohms.

Do not hot wire it for more than 30seconds at a time. letting it cool for 2 minutes before second attempts.

set hot idle here, screw it in to lower idle to 800 RPM

If the idle bleed screw above, is dead acting?(you spinning it cw/ccw) or weak, but turns, you have very bad plenum air leaks. (or motor AFR is super lean)

THE IAC PLUNGER, is a 100% water coolant activated device. (simular in action to a coolant thermostat using a wax pellet inside (expands fast when heated))

This part below IAC, can not be serviced, except cleaning it? and silent prayer. (over night soak with carb cleaner? )

This IAC plunger , the cold start fast idle device. (below)

The spec. for this device is: (spec. means, factory peformance specifacations...)

The 1.8 Liter works in the same ways as the G16B , has just an ISC (soleniod ) and this plunger device.(IAC water heated)

The "A" dimension is 1.048 to 1.078" @ 25deg C or 77F and fully retracts off cam at 126 to 154deg F.

It opens only for cold starts, then retracts the throttle. That cam below is the throttle valve shaft.

http://www.fixkick.com/IDLE-AIR/J18-idle.html

http://www.fixkick.com/IDLE-AIR/J18-idle.htmlThe 1.8L Idle bleed (hot idle set) screw. (below)

irst make sure the CEL lamp is on , at

key on , and goes out

running, if not, correct those

issues, first. (redundant to

link marked "Dream", at top of page)

irst make sure the CEL lamp is on , at

key on , and goes out

running, if not, correct those

issues, first. (redundant to

link marked "Dream", at top of page)

Happy Trails to all !

The Air supplies to the induction system must work correctly and there must be no illegal air leaks, cracks, breaches ,below the Throttle plate on the 1.8L

rev 2 1-21-2013