1.6L and 1.8L < see the Sport now.

Sloppy shifter? < first things first !

Can't even shift with keys in your pocket?

Can't hit all gears. (feel it?) Shifter is floppy, like a dogs tail?

If you can't actually shift the gears , first and foremost. replace the 2 plastic SUZUKI parts shown in this PARTS PHOTO Part ID 19 and 27 (click)

No aftermarket maker ,makes these plastic shifter parts.

The aftermarket makers, do not make 5 speed parts. (only clutches, cables, bearings , and sychro rings, no pedals are made, no gears, no cases

THE CABLE DON'T LAST FOREVER: ( all ugly photo's are from OWNER abuse, cracked firewall, and broken clutch pedal or it's shaft ) Slide show here?

Always, replace the clutch cable first, for $23 before ever condemning expensive parts and huge 4 to 8 hour labor charge on 4wd .

The cable goes bad INSIDE (channel groving it and jamming it) where YOU CAN NOT SEE IT. Get it out of there, now and save a bundle.

Or learn old school Harely cable lubing ways.....

See Diagnosis here, See how to drive with a bad clutch here. See causes of Noise here.

All my comments are 100 % USA/ and Canada.

Other countries use different parts or at different years,. and different non OEM parts, sold in your country.!

My page has secrets, not disclosed in any book, FSM or Suzuki shop manual.

Never skip checking the quality of GL4 Gear lube in the tranny or the proper level? (not looking like tar sands? in Canada?)

Hints:

The reverse gear is the "Canary bird" (coal miners rule) that grinds at the slightest amount of clutch drag. (REV gear, is a non synchromeshed gear )

The synchro's job is only to overcome the inertia of the disengaged free running, input shaft pinion.

The synchro can not hide a bad dragging clutch disc, not at all. (or a seizing fly pilot bearing)

There is 80-95HP there, fighting the poor little brass synchro ring. "yes, it will torture it to death too" if you ignore it.

Clutches, can drag or slip, or chatter, and even make noises.

Set the free play first, then make sure Reverse don't grind. ( a bad clutch cable, can cause, gear grinding as you shift)

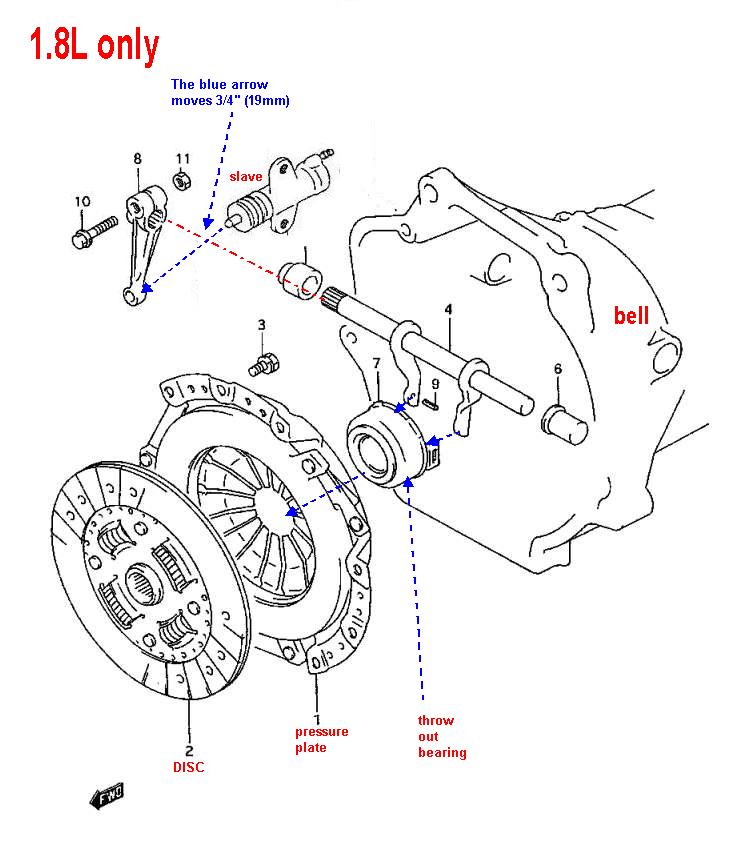

The 1.8L J18 Sport has an autoadjusting slave cylinder. (hydraulic) as does all our 1999 + Vitara's

ACTUAL CLUTCH FAILURE Section:

The Clutch: 1.6L (8v shown, but 16v looks same) This is a new Exidy clutch. A good brand, as is LUK. Do not buy a fleabay $50 clutch kit. (China C4)

The SQUAWKS : (problems, issues, complaints, or symptoms)

The cable is NEW and adjusted before below:. The below, are all bad clutches, except the last 2

- Grinding in all 6 gears.

(this is a dragging disc or bad flywheel pilot bearing.)? Reverse

is a gear and must not grind, shifted not moving.

- Clutch slippage under loads, the more, load the more slip.? {disc worn to rivets, oil soaked, or media missing chunks}

- Selecting any gear, is near impossible. called BALKING, , and if I brute forced, it into gear (don't) it grinds.? Is clutch Drag.

- The disc Drags for

ANY REASON? Car jerks as you release the clutch.? (or chatters

just before)

- Car likes to move in 1st/Rev gear, with clutch pedal, to floor.? parked? (aka. dragging clutch)

- Clutch chatters, on

release/or engagements. (a bad disc or warped/cracked pressure

plate, oil

soaked)? or damaged flywheel face.

- Makes noise. (if you only get noise with tiny pressure on the clutch pedal, that is a bad throw out bearing)?

- Smokes? (it's slipping and smoking or oil soaked ( 2 seals to check !)

- Grinding in one gear (1st to 2nd or 3rd to 2nd can be a bad synchro ring. 2nd is high wear synchronizer. (a town car, this wears first)

- The front box pilots

shaft spline can be galled or abraided so bad, the disc internal

spline, sticks. Replace the shaft (sold at Suzuki only).

- Bad Transmission input bearing causing

clutch failure or the seal on same leaking GL4 (gear lube) on to DISC.

The transmission is a "constant gear mesh box" but the dogs do the lockup, the dogs are synchro dogs (top center in view).

It's purpose, is to allow shifting when the tranny input shaft is at a lower RPM. ( in a race car we delete this part, and double clutch.)

A bad clutch, is any part failing in side the BELL HOUSING. Clutch action related.

NOISE: (causes)

A clutch can in fact fail in one or more ways and make noise (neglect or abuse, are a top causes)

Here is one example of a bad clutch:

Bad throwout bearing, and the DISC has lost a segment of media between rivets and the pressure plate is cracked and to top that off,

the one torque reaction spring in the center of the disc is broken and lastly ,one pressure plate pivot (hinge) is broken off.

This clutch slips and rattles and knocks and bangs, and makes every sound you can imagine and is out of balance.

Seen it! (in fact, caused it racing cars)

The Tranny input shaft has 4 major failures , in its own right, galled spline, front pilot bearing mount wrecked, rear bearing fail or seal.

If the tranny has 20 year old GL4 lube , still in the box and looks like TAR, why are you looking here?

Checks: G16 based cars.

The prerequisite for the below, is to set the clutch free play at the pedal to about 1/2" inch. 12mm

This step is a 15,000 miles FSM and glove box listed Service point. That nobody does, it seems.

Normal clutch wear , decreases this free play calibration ,see video for animation of this clutch (nice).

Allowing zero play to happen, burns up the bearing #6 fast, and eventuully the clutch slips on hills, and then that burns up, a good clutch disc or PP.

PAGE 1 , ITEM ONE , NO LESS ! oops , you forgot now clutch is burned up. Sorry!

Cross section view diagram of a clutch, shows how it moves, as does the video above.

LOGIC (new) Cable clutch only.

- Inspect the mechanical linkage end to end , this is 1st, never last ! Do not skip any portion of the linkage , end to end !

- Look for a broken pedal welds (every millimeter of pedal and pivot)

- Look for a stripped spline or spline shaft welds broken See slide show for Lever splines all other failed parts

- Replace the damaged cable, if it looks bad. (or if 100k miles old) This is a service point. (most cable fails are hidden deep inside)

- Do my secret one inch rule test, below, at the clutch bell housing lever END. (bottom end must move 1 inch with full pedal travel )

- If #1 to 5 fails , stop and correct this serious problem first. (first things first? huh?)

- Keep in mind the PO, (prev. owner) might have been on drugs and set it up all wrong.

- If all the above passes muster, then the clutch is bad, it dont matter why! , it is bad, and which of the 5 parts bad is a moot point, because all will be changed with the kit.

- The below shows tests and reasons for failure. ( the 5th test is only an EYEballs test, which either passes or fails

The many parts that fail.

Clutch disc (worn to the media rivets, and/ or cracked or warped)

Clutch pressure plate ( cracked or warped same with springs inside and spring tip damage)

Clutch throw out bearing ( aka, release bearing, or T/O bearing, or just T/O) is burned up, bad, noisy/seized , or mangled to the extreme.

Clutch flywheel Pilot bearing. (if seized car will move in 1st gear , with clutch disengaged.

The main tranny input shaft spine and end part, can fail too. ( galled, or damaged causing disc to stick)

The tip of the input shaft can be gone, worn down, such that, it dont ride in the bearing any more, this can make clutch chatter. (new shaft or weld and machine are 2 fixes)

The front 2 bearings on the tranny can fail, this is not clutch failure, but is some thing to check , with open BELL. does Pilot shaft wiggle side to side ? yes =bad.

The T/O bearing has an Engagement cross shaft lever and bushings, all can fail, check closely for damage.

The Bell is the Bell housing....

Comments:

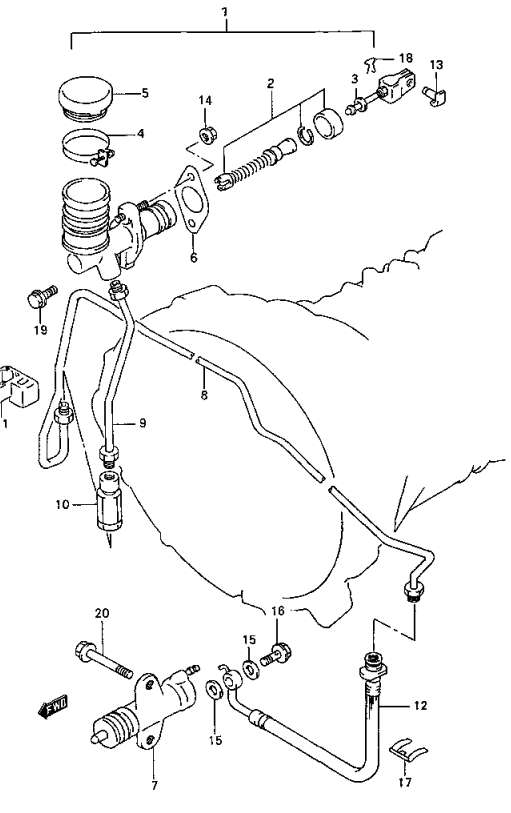

This is my 1.6L 8valve kick engine and new stock clutch. FAST CABLE FINDER:

Below , is the schematic of the whole mechanical clutch system. (pilot bearing and tranny input shaft not shown) [non SPORT 1.8L]

| This goes without saying but we keep

having to repeat this on the forum over and over...... Before replacing any difficult clutch part , always inspect the system that is exposed (in plain view with EYEBALLS). Top side, bottom side and end to end. This applies to all machines, car, boat ,plane,whatever. Look for damage. including road hazard damage. stuff happens. Things rust , break, or get ignored. This applies to the 1.8L hydraulic. clutch linkage too. |

Before condemning any clutch, examine the cable #15 for damage of any kind, the sheath and the actual internal cable at both ends.

Old 150k mile cables do 2 thing , they fray inside where you can't SEE, and worse the wear and inside sheath groove(hidden) that cause the cable to jam ,jerk and snatch.

The cable is cheap and 1 hour labor why do folks assume its good, when in fact it can not be inspected? Replace it FIRST.

No fraying or damage can be allowed . The sheath must not be worn through at any point, of its length.

The cable lasts about 100k miles in the city . and goes bad where no man can see , inside. (internal hidden damage is 90% of the cable fails)

See bottom of this page links for actual adjustments of the clutch. Full procedures.

Set the free pedal Height first then the clutch pedal free play.

The two dimensions below 11-1/8 and 8-1/2 are off my 8v car, and are shown, because I have learned that many people get sold the wrong cable or some piece of Garbage from China. ( there are 3 stock cables sold depending on body type , see last paragraph for Suzuki PN)

Next see my Part 18/19 moves 1.0 inch rule.

( the 1.8L hydraulic. stroke rule is rumored to be 3/4" 0.75" stroke at slave rod)

Mech. Clutch 100%:

Rule ONE, if reverse grinds (it's not a synchro) then its not the tranny bad !!! < FACT !

The acid test. ( no where is this secret told, but here)

1: Free play in cable is set to 1/4-1/2 inch , at clutch pedal. using the nut 19,. (CW from end removes play)

2: Gently move lever 11 (shown upside down below ,sorry, see real here and index mark) until you feel the yoke 5 arms hit the throwout bearing #4.

3: Now have a helper depress the clutch pedal to the floor boards.

4: Did the end of the cable at 18/19 juncture lever 11 tip , move at LEAST 1 inch? if not , then remove all play in step one and repeat step 4.

Yes 1? INCH, and the clutch fails?, then the clutch is bad. Reverse grinding is NEVER A BAD TRANSMISSION. It's NON-Synchro (the canary in the mine)

No ?1 INCH then the cable is bad or the pedal assembly is broken or the cable mounts at 21 or 16 points are cracked , or badly damaged. USE 2 persons to test the clutch.

Bad splines , split shank on part 11 bellow or Drawing B part 21 spline split or pedal cracked.

Keep in mind that at no time, can the outer sheath of the cable, must never actually move, (twitch a tad is ok). Takes 2 persons to do that !!

If the 1 inch rule passes, the clutch is no good. (if you cant shift with zero pedal play, or the clutch slips like crazy , or the tranny grinds ,then the clutch is bad)

If tranny stops grinding in Reverse and now shifts perfectly?, try getting the free play at #1 set correct. ON cable systems, it's hard to feel this play.

Drawing A:

Early car with threaded mount at 21, Nut 19 adjusts free play , never then nuts on bracket 21, 21 is just a MOUNT.

Later cars have a rubber fast mount at 21. (do not mix cables , get the correct cable)

ID. #11 looks upside down, and is a little lie, of the draftman to make drawing compact for parts sales. (only)

Part #18 fits into the bottom of #11 (top here) in the round hole of #11

The 1" inch rule is with 11 slack gone and 11 moves 1" inch for full pedel travel. (my rule)

20mm is about 3/4" free play. Very hard to feel with a bad cable, sure.

External to clutch damage, is big time common.

Drawing B: below: Click image below to see key partnumbers.

Lever 25 below attaches (hooks ) to end of cable shackle at 15/16 bolt above. See slide show?

Typical damage from using a bad cable are:

- Part 25 wrecked. (bent to hell)

- Spline 21 stripped at above or at spline or both.

- Fire wall cracked cable mount.

- Pedal broken. at base of spine shaft 21.

Any weld shop ,worth salt, can fix this damage, why wait for Suzuki's long delays getting this part. 14 days? (from purgatory warehouse)

Welding the pedal break left, @21 is childs play, (to any welder) the spline strip, you could remove part 35 from fire wall, insert the 21 in to 35, and weld on, part 25 using the index punch marks, at at 25 and end of spline!

See the Suzuki official partnumbers for 16 to 31 here.

Special thanks to all people on the Suzuki forum for posting great

failure photos !

Special thanks to all people on the Suzuki forum for posting great

failure photos !